Preparation method of sulfonated bisphenol A-formaldehyde condensate superplasticizer

A formaldehyde condensate and high-efficiency water-reducing agent technology, applied in the field of high-efficiency water-reducing agent and production, can solve problems such as human harm and environmental pollution, and achieve the effects of saving material costs, reducing sewage costs, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

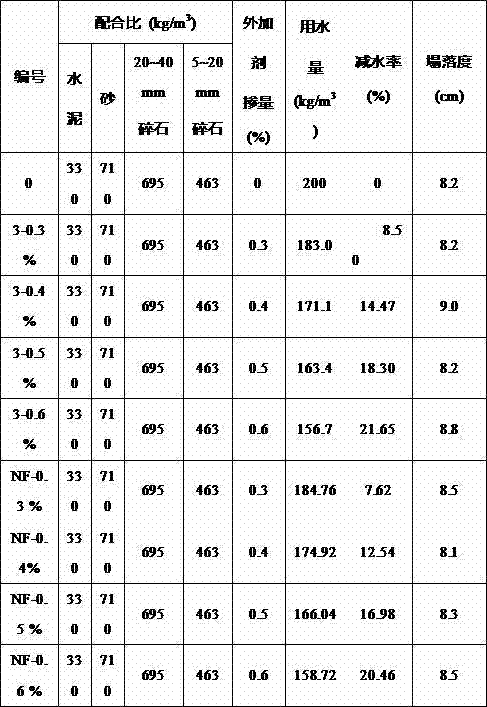

Examples

Embodiment 1

[0019] Weigh 240Kg of bisphenol A, 85Kg of sodium bisulfite and 490Kg of water into a reaction kettle equipped with a stirrer, thermometer, dropping funnel and reflux condenser, start the stirrer, and stir until bisphenol A and sodium bisulfite are completely Dissolve in water to form a uniform solution; dropwise add sodium hydroxide with a mass fraction of 20% to adjust the pH of the solution to 1.5, and raise the temperature to 70°C; maintain the temperature of the solution at 70°C, and slowly add 170Kg mass fraction dropwise while stirring It is a 37% formaldehyde solution, and the formaldehyde solution should be added within 1 hour to avoid gelation caused by too fast formaldehyde drop rate; heat up to 90°C, keep warm for 5 hours, add 20Kg of urea to remove a small amount of formaldehyde in the solution, After the reaction reaches the end point, stop the reaction, cool naturally to room temperature, and mature the product in the reactor for 5 hours to obtain a deep red sulf...

Embodiment 2

[0021] Weigh 250Kg of bisphenol A, 90Kg of sodium bisulfite and 495Kg of water into a reaction kettle with a stirrer, thermometer, dropping funnel and reflux condenser, start the stirrer, and stir until bisphenol A and sodium bisulfite are completely Dissolve in water to form a uniform solution; dropwise add sodium hydroxide with a mass fraction ratio of 20% to adjust the pH value of the solution to 11, and raise the temperature to 70°C; maintain the temperature of the solution at 70°C, and slowly add 175Kg mass fraction dropwise while stirring It is a 37% formaldehyde solution, and the formaldehyde solution should be added within 1 hour to avoid gelation caused by too fast formaldehyde drop rate; heat up to 95°C, keep the temperature for 7 hours, add 30Kg of urea to remove a small amount of formaldehyde in the solution, When the reaction reaches the end point, stop the reaction, cool naturally to room temperature, and mature the product in the reactor for 6 hours to obtain a d...

Embodiment 3

[0023] Weigh 246Kg of bisphenol A, 88Kg of sodium bisulfite and 493Kg of water into a reaction kettle with a stirrer, thermometer, dropping funnel and reflux condenser, start the stirrer, and stir until bisphenol A and sodium bisulfite are completely Dissolve in water to form a uniform solution; dropwise add sodium hydroxide with a mass fraction ratio of 20% to adjust the pH value of the solution to 10.5, and raise the temperature to 70°C; maintain the temperature of the solution at 70°C, and slowly add 173Kg mass fraction dropwise while stirring It is a 37% formaldehyde solution, and the formaldehyde solution should be added within 1 hour to avoid gelation caused by too fast formaldehyde drop rate; heat up to 93°C, keep warm for 6 hours, add 25Kg of urea to remove a small amount of formaldehyde in the solution, When the reaction reaches the end point, stop the reaction, cool naturally to room temperature, and mature the product in the reactor for 6 hours to obtain a deep red s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com