A kind of environment-friendly low-cost sulfamate superplasticizer preparation method

A sulfamate and high-efficiency water reducing agent technology, applied in the field of concrete materials, can solve problems such as high price and environmental pollution, and achieve the effects of saving material costs, improving production environment, and reducing investment in production equipment and factory fixed assets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of environmentally friendly low-cost sulfamate superplasticizer.

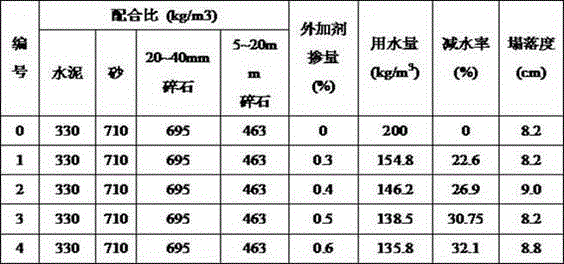

[0024] Accurately weigh 210-215kg of polyphenols and 175-180kg of sodium sulfamate solid into a reaction kettle equipped with a stirrer, thermometer, dropping funnel and reflux condenser, and then add 370-375kg of water. Start the stirrer and stir, so that the solid polyphenol and sodium sulfamate are completely dissolved in water and become a uniform solution. The mixed solution is slowly warmed up to 70-80° C., and the pH value of the reaction system is adjusted to 10-11 with 20% sodium hydroxide solution to keep the solution without insoluble matter. Keep the temperature of the reaction solution at 80°C, slowly add 235-240kg of formaldehyde solution (37% concentration) dropwise, and control the formaldehyde solution to be added within 1 hour. Then the temperature of the solution was raised to 90° C. for 4 hours. After the reaction, a small amount of urea is added to remove a small am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com