A kind of preparation method of monocyclic aromatic hydrocarbon type high-efficiency water reducer

A technology of high-efficiency water reducer and single-ring aromatic hydrocarbon, which is applied in the preparation of high-efficiency water reducer and single-ring aromatic type high-efficiency water reducer, and can solve the problem of high price and restriction of large-scale use of AH single-ring aromatic type high-efficiency water reducer , application range limitations and other issues, to achieve the effects of reducing the discharge of toxic substances and strong alkali solutions, improving bleeding performance, optimizing molecular weight and molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

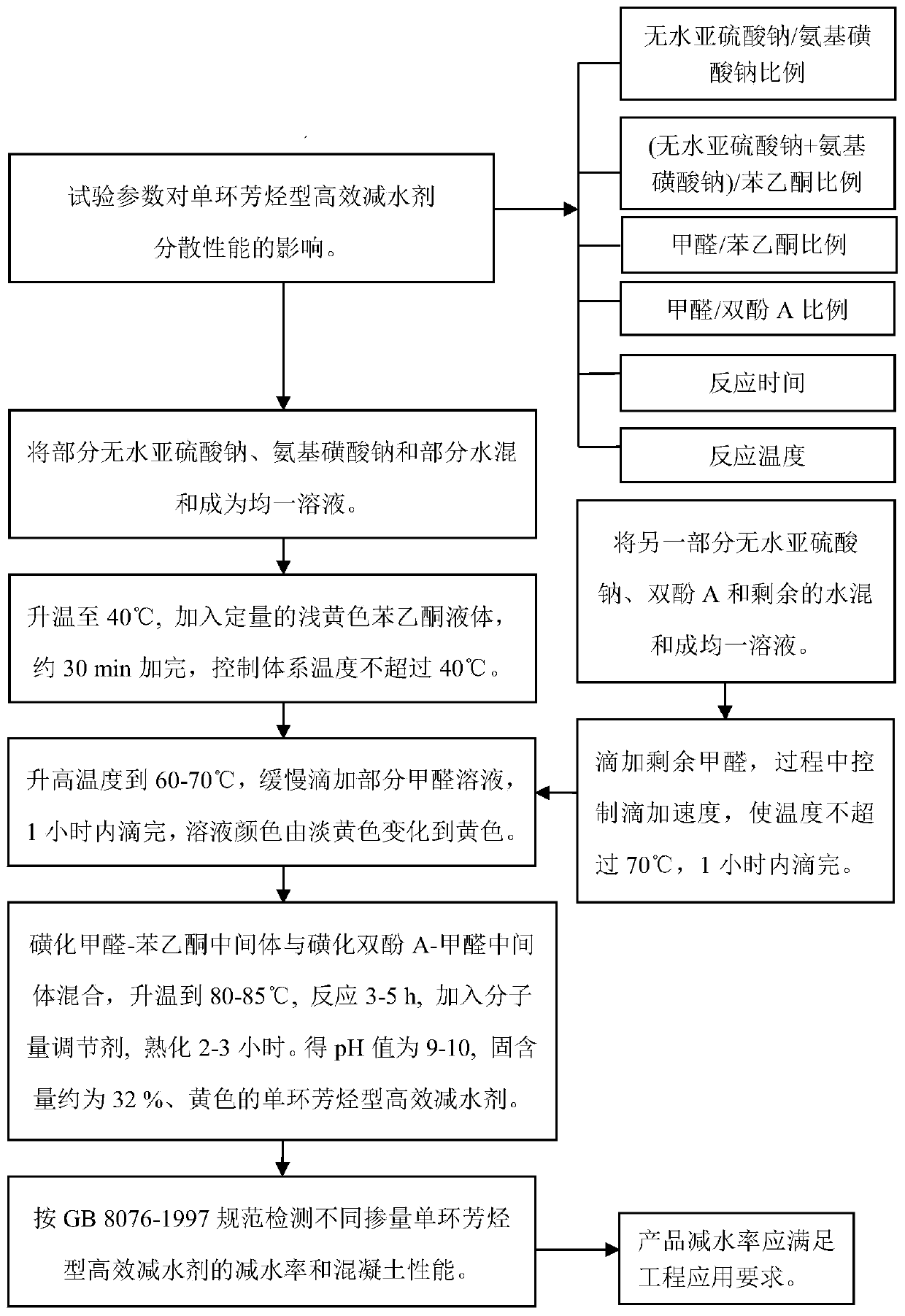

[0033] A method for preparing a monocyclic aromatic hydrocarbon type high-efficiency water reducer, the flow chart is as follows figure 1 shown, including the following steps:

[0034] Step 1, adding a part of anhydrous sodium sulfite and sodium sulfamate into water in sequence according to the mass ratio, stirring and dissolving, raising the temperature to 50°C, so that anhydrous sodium sulfite and sodium sulfamate are completely dissolved in water to form a uniform solution;

[0035] Step 2, continue to stir the solution, reduce the temperature of the solution to 40°C, gradually add acetophenone liquid into the reaction vessel, control the temperature of the system not to exceed 40°C, and complete the addition within 30 minutes;

[0036] Step 3. Raise the temperature of the solution to 60-70°C. Slowly add part of the formaldehyde solution dropwise under rapid stirring to avoid gelation caused by too fast drop rate of formaldehyde. During the entire process of adding formalde...

Embodiment 1

[0043] Weigh 35kg of anhydrous sodium sulfite and 60kg of sodium sulfamate into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, and add 250kg of water. Start the mixer and stir at a certain speed. Raise the temperature to 50°C to completely dissolve anhydrous sodium sulfite and sodium sulfamate in water to form a uniform solution. Continue to stir the solution, reduce the temperature of the solution to 40°C, gradually add 95kg of light yellow oily acetophenone liquid into the reaction vessel, control the system temperature not to exceed 40°C, and finish adding the acetophenone liquid within 30 minutes. Raise the temperature of the solution to 60°C, slowly add 125kg of formaldehyde solution dropwise under rapid stirring, and finish adding the formaldehyde solution dropwise within 1 hour. The color of the solution changes from light yellow to yellow, and sulfonated formaldehyde-benzene Ethanone condensation intermediate. The...

Embodiment 2

[0045] Take by weighing 30kg of anhydrous sodium sulfite and 60kg of sodium sulfamate and put it into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, and add 245kg of water. Start the mixer and stir at a certain speed. Raise the temperature to 50°C to completely dissolve anhydrous sodium sulfite and sodium sulfamate in water to form a uniform solution. Continue to stir the solution, lower the solution temperature to 40°C, gradually add 90-95kg of light yellow oily acetophenone liquid into the reaction vessel, control the system temperature not to exceed 40°C, and add the acetophenone liquid in about 30 minutes. Raise the temperature of the solution to 60°C, slowly add 120kg of formaldehyde solution dropwise under rapid stirring, and drop the formaldehyde solution within 1 hour. The color of the solution changes from light yellow to yellow, and sulfonated formaldehyde-benzene Ethanone condensation intermediate. Then, add 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com