Method for preparing fluid loss agent

A fluid loss reducing agent and solvent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of layered collapse of the fluid loss reducing agent, application limitations, and affecting the performance of the fluid loss reducing agent, etc. The effect of improving the ability to carry cuttings, strong inhibition and tolerance, and the best hole cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

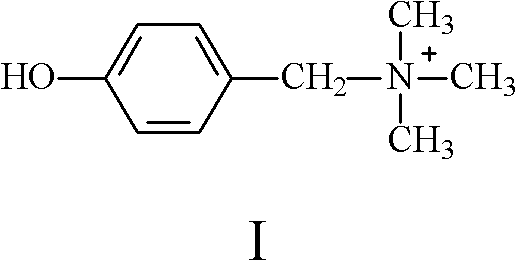

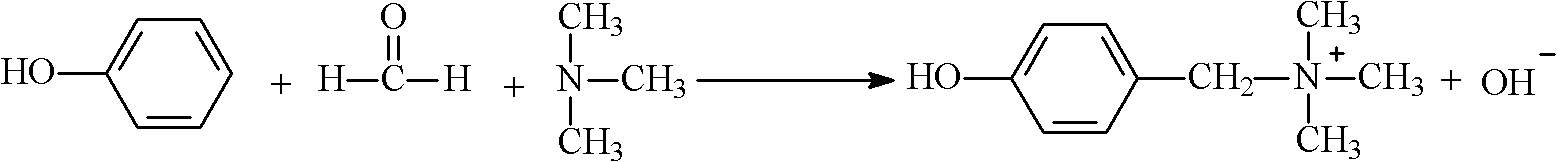

[0027] The invention provides a method for preparing a fluid loss reducer, comprising: a) mixing phenol, sulfuric acid, trimethylamine and a first solvent, and reacting to generate cationic phenol;

[0028] b) mixing and reacting the aqueous alkali solution, lignite, and the second solvent to obtain sodium humate slurry;

[0029] c) mixing the sodium humate slurry with cationic phenol, sodium sulfite, and a third solvent to undergo a polymerization reaction to obtain a fluid loss reducer.

[0030] In the exploration industry such as drilling or petroleum, with the different geological structure and soil composition, it is necessary to use different fluid loss reducers and other methods to improve the ability of the capillary channels in the mud cake formed by drilling fluid and soil, so the reduction The selection of fluid loss agent is very important. In some soils, metal ions such as Mg, Ca, Na, K, and Al are rich in content. Application of water loss agent. The fluid loss...

Embodiment 1

[0041] at 1 # Add 300 kg of water, 300 kg of phenol, 80 kg of trimethylamine and 53 formaldehyde to the reaction kettle, start stirring, slowly add about 13.3 kg of sulfuric acid until the pH value of the reaction solution remains at 6, raise the temperature to 65°C, and react at this temperature for 60 minutes , to obtain a cationized phenol mixture.

[0042] at 2 #Add 2500 kilograms of water and 800 kilograms of lignite to the reaction kettle, start stirring, slowly add 260 kilograms of sodium hydroxide aqueous solution, the mass concentration is 30%, heat up to 70 ° C, and react at this temperature for 30 minutes, and centrifuge to separate the insoluble residue to obtain Sodium humate slurry.

[0043] With stirring, the 2 # Pump the sodium humate slurry obtained in the reaction kettle into the 1# reaction kettle, add 122.7 kg of liquid caustic soda, 305 kg of sodium sulfite, and 746 kg of formaldehyde solution with a mass concentration of 37%, seal the reaction kettle, ...

Embodiment 2

[0060] at 1 # Add 310 kg of water, 310 kg of phenol, 80 kg of trimethylamine and 53 formaldehyde to the reaction kettle, start stirring, slowly add about 13 kg of sulfuric acid until the pH value of the reaction solution remains at 7, raise the temperature to 65°C, and react at this temperature for 60 minutes , to obtain a cationized phenol mixture.

[0061] at 2 # Add 2510 kilograms of water and 780 kilograms of lignite to the reactor, start stirring, slowly add 270 kilograms of sodium hydroxide aqueous solution, the mass concentration is 30%, heat up to 70 ° C, and react at this temperature for 30 minutes, and centrifuge to separate the insoluble residue to obtain Sodium humate slurry.

[0062] With stirring, the 2 # Pump the sodium humate slurry obtained in the reaction kettle into the 1# reaction kettle, add 123 kg of liquid caustic soda, 300 kg of sodium sulfite, and 750 kg of formaldehyde solution with a mass concentration of 37%, seal the reaction kettle, heat up, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com