High-elasticity sponge applied to child safety seat and making method of sponge

A child safety seat and sponge technology, applied in the field of high-elastic sponge production, can solve the problems of no sterilization effect, poor use comfort, poor cushioning effect, etc., to prevent caking, increase compression resistance and cushioning performance, and make low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

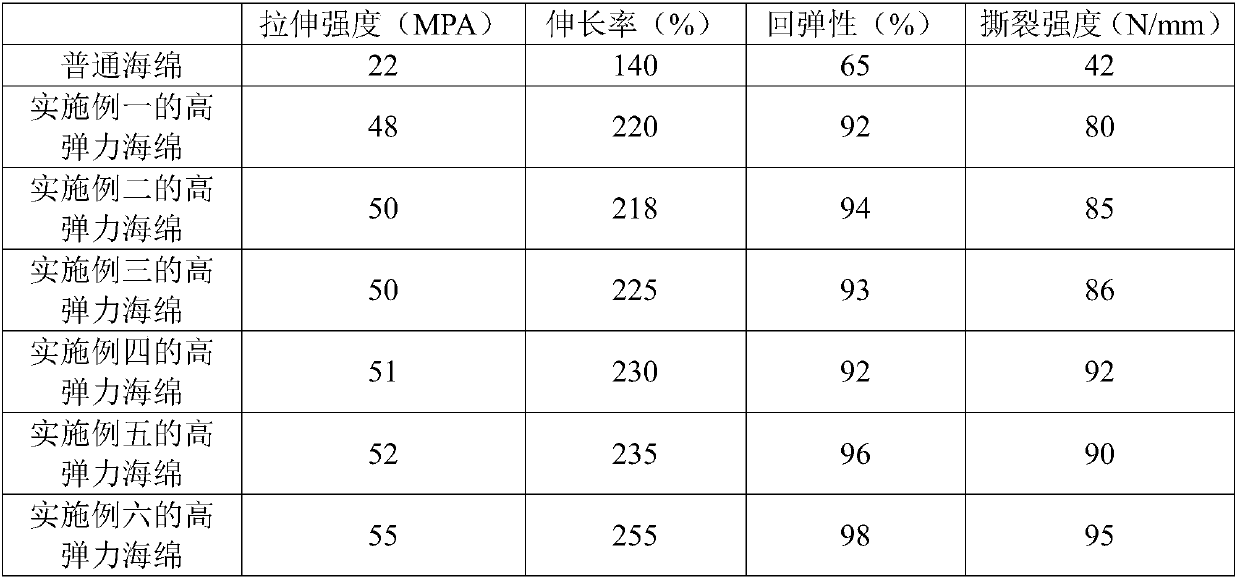

Examples

Embodiment 1

[0018] A high-elasticity sponge applied to child safety seats, consisting of the following components by weight ratio:

[0019] The high elastic sponge components include 40 parts of sponge foam material, 10 parts of activated carbon, 5 parts of carbon cellulose, 4 parts of toluene diisocyanate, 8 parts of polysiloxane, 10 parts of soft foam silicone oil, and 4 parts of chlorinated paraffin in parts by weight. , 3 parts of elastin, 3 parts of rubber thread, 4 parts of latex thread, 3 parts of elastic thread, 15 parts of acrylic glue.

[0020] The production method of this embodiment comprises the following steps: weighing each raw material according to the above-mentioned parts by weight, and making according to the following steps:

[0021] M1: Mix activated carbon, carbon cellulose, toluene diisocyanate, polysiloxane, and soft foam silicone oil and put them into a stirring tank to stir to obtain a mixture A, wherein the stirring rate of the stirring tank is 400 rpm for 15 mi...

Embodiment 2

[0026] A high-elasticity sponge applied to child safety seats, consisting of the following components by weight ratio:

[0027] The high elastic sponge components include 60 parts of sponge foam material, 20 parts of activated carbon, 15 parts of carbon cellulose, 12 parts of toluene diisocyanate, 18 parts of polysiloxane, 20 parts of soft foam silicone oil, and 10 parts of chlorinated paraffin in parts by weight. , 9 parts of elastin, 12 parts of rubber thread, 12 parts of latex thread, 10 parts of elastic thread, and 25 parts of acrylic glue.

[0028] The production method of this embodiment comprises the following steps: weighing each raw material according to the above-mentioned parts by weight, and making according to the following steps:

[0029] M1: Mix activated carbon, carbon cellulose, toluene diisocyanate, polysiloxane, and soft foam silicone oil, and then put them into a stirring tank and stir to obtain a mixture A, wherein the stirring rate of the stirring tank is...

Embodiment 3

[0034] A high-elasticity sponge applied to child safety seats, consisting of the following components by weight ratio:

[0035] The high-elastic sponge components include 45 parts of sponge foam, 12 parts of activated carbon, 7 parts of carbon cellulose, 6 parts of toluene diisocyanate, 9 parts of polysiloxane, 12 parts of soft foam silicone oil, and 6 parts of chlorinated paraffin in parts by weight. , 4 parts of elastin, 5 parts of rubber thread, 5 parts of latex thread, 4 parts of elastic thread, 17 parts of acrylic glue.

[0036] The production method of this embodiment comprises the following steps: weighing each raw material according to the above-mentioned parts by weight, and making according to the following steps:

[0037] M1: Mix activated carbon, carbon cellulose, toluene diisocyanate, polysiloxane, and soft foam silicone oil, and then put them into a stirring tank and stir to obtain a mixture A, wherein the stirring rate of the stirring tank is 500 rpm, and the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com