Friction material for magnetically levitated train and preparation method and application thereof

A technology of magnetic levitation trains and friction materials, applied in friction linings, mechanical equipment, transportation and packaging, etc., can solve the problems of large wear, short service life, poor friction coefficient stability, etc., achieve small wear, improve service life, and stable good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

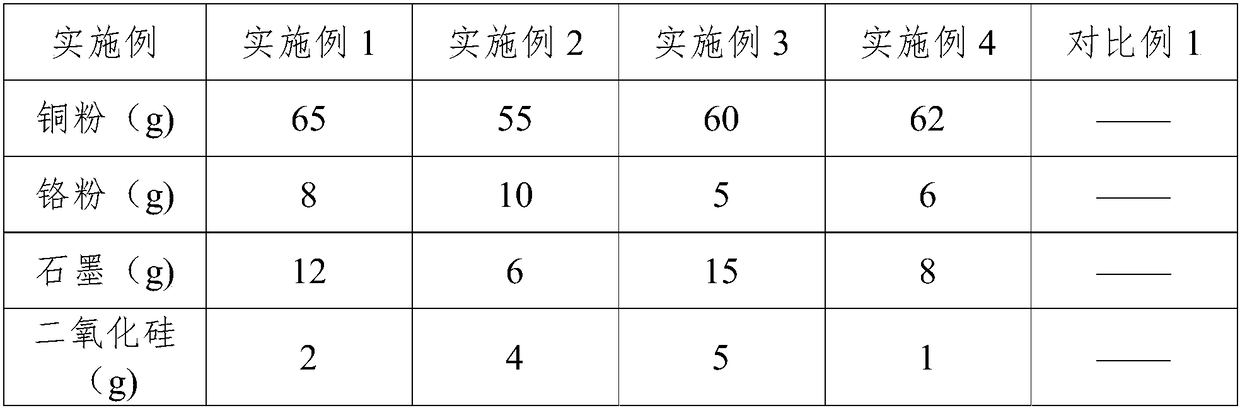

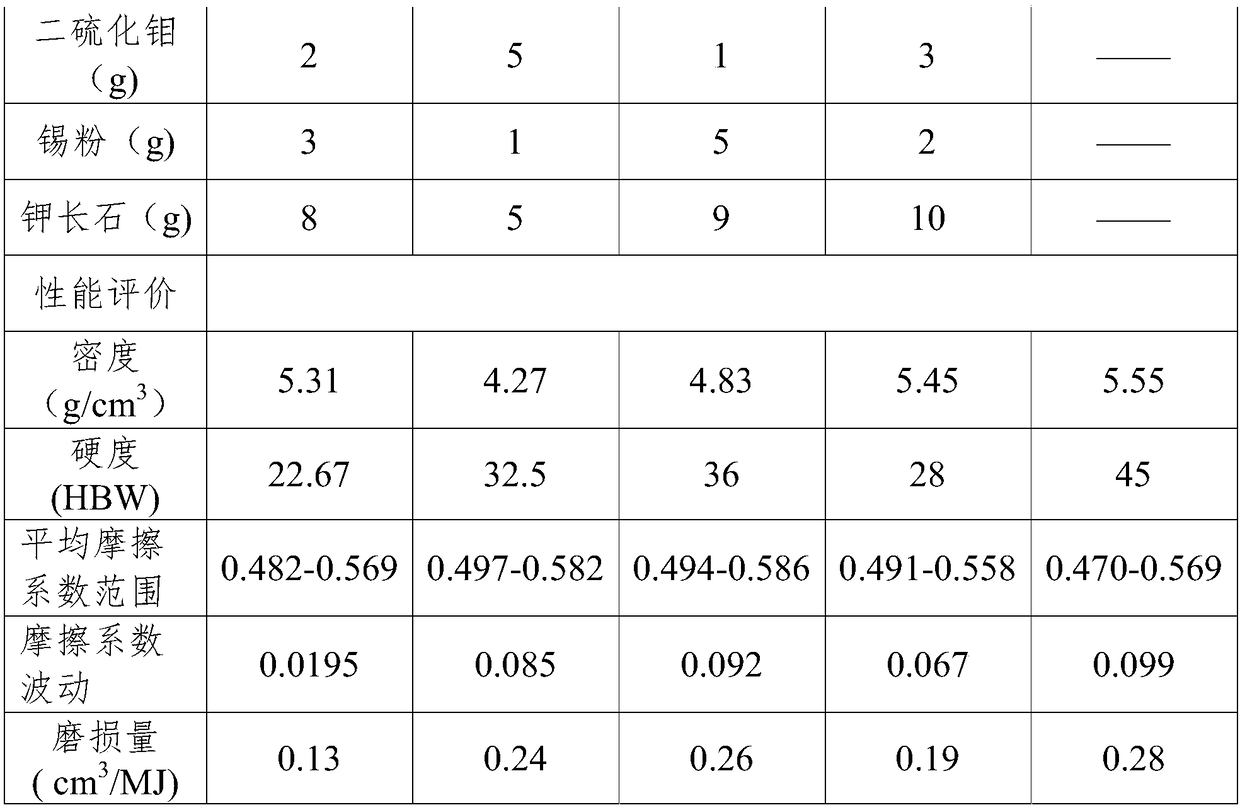

Embodiment 1

[0028] The raw material composition of the friction material is as follows: copper powder 65g, chromium powder 8g, graphite 12g, silicon dioxide 2g, molybdenum disulfide 2g, tin powder 3g, potassium feldspar 8g;

[0029] Add the above-mentioned raw materials into a V-type mixer for mixing, and add 5 g of alcohol with a volume fraction of 10% at the same time, mix the materials for 2 hours, then add them to a hydraulic press for compression molding, the compression pressure is 5 MPa, and the compression time is 5 seconds. After the compression molding, add bell The sintering is carried out in a bell furnace with hydrogen as the protective gas in the bell furnace, the sintering temperature is 860°C, and the sintering time is 3h, and the friction material is made.

Embodiment 2

[0031] The raw material composition of the friction material is as follows: copper powder 55g, chromium powder 10g, graphite 6g, silicon dioxide 4g, molybdenum disulfide 5g, tin powder 1g, potassium feldspar 5g;

[0032] Add the above raw materials into a V-type mixer for mixing, and at the same time add 3.44g of alcohol with a volume fraction of 5%, mix for 2h, then add to a hydraulic press for compression molding, the compression pressure is 6MPa, the compression time is 8s, after compression molding Put it into a bell furnace for sintering. In the bell furnace, hydrogen is used as a protective gas. The sintering temperature is 850°C and the sintering time is 2h to make a friction material.

Embodiment 3

[0034] The raw material composition of the friction material is as follows: copper powder 60g, chromium powder 5g, graphite 15g, silicon dioxide 5g, molybdenum disulfide 1g, tin powder 5g, potassium feldspar 9g;

[0035] Add the above raw materials into a V-type mixer for mixing, and at the same time add 3g of alcohol with a volume fraction of 5%, mix for 2 hours, and then add it to a hydraulic press for compression molding. The compression pressure is 7MPa, and the compression time is 6s. After compression molding, add The sintering is carried out in a bell furnace, where hydrogen is used as a protective gas, the sintering temperature is 900°C, and the sintering time is 2.5h, and the friction material is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com