Filtering membrane for treating volatile organic compounds

A volatile organic compound and filtration membrane technology, applied in the field of membrane material preparation, can solve the problems of difficult absorption and treatment of VOCs, secondary pollution, and high processing costs, and achieve the effects of good seismic performance, high absorption efficiency and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

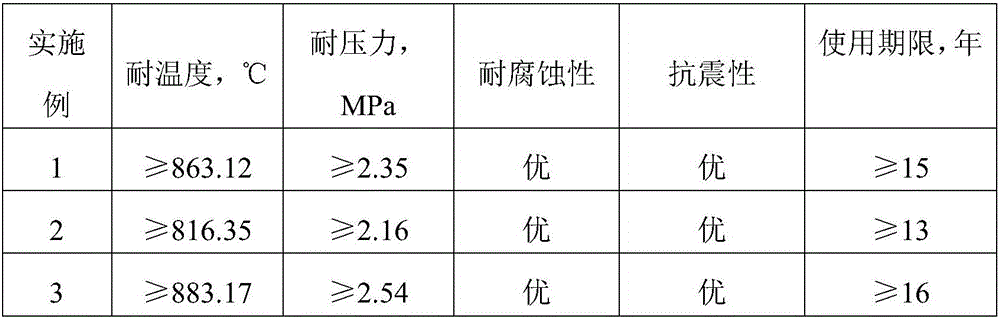

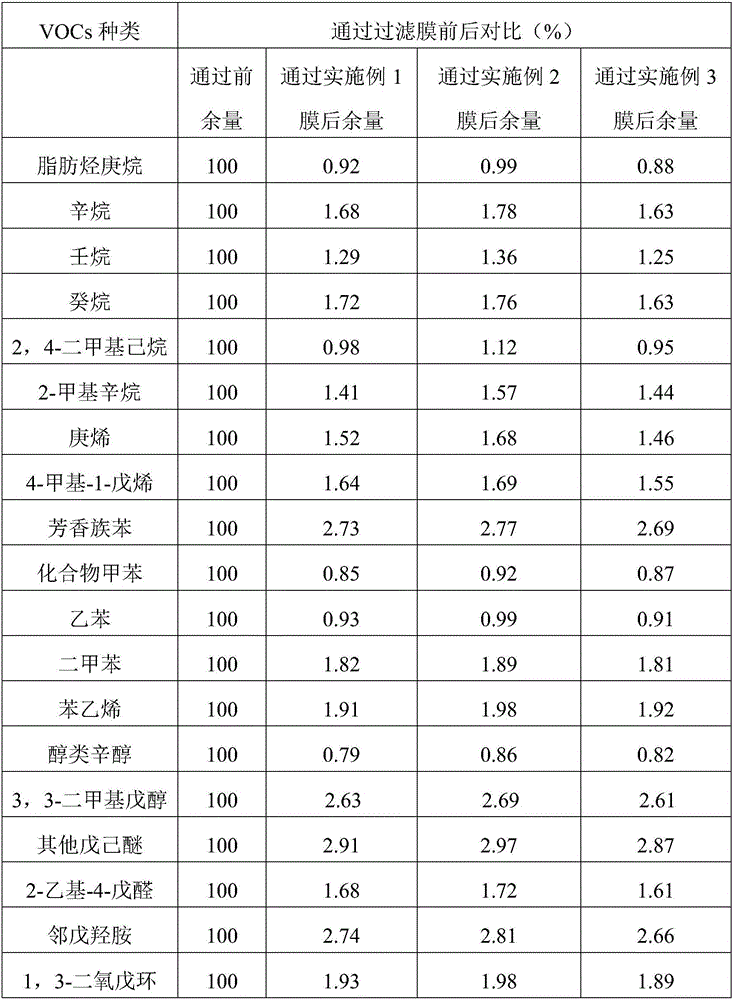

Examples

preparation example Construction

[0033] The preparation method of the filter membrane for controlling volatile organic compounds, comprises the following steps:

[0034] S1: Soak feldspar, quartz, sodium silicate, activated carbon, zeolite, and diatomaceous earth in deionized water to wash off the attached pollutants, then dry them until the water content is ≤1.8%, and then dry the dried feldspar , quartz, sodium silicate, activated carbon, zeolite, diatomaceous earth, carbon fiber, and glass fiber are placed in a nano pulverizer, pulverized at a speed of 400-800r / min for 2-3 hours, and then passed through a sieve to obtain a nano-mixed powder;

[0035] S2: uniformly mixing the nano-mixed powder prepared in step S1 with a catalyst, a crosslinking agent, a tackifier, a plasticizer, a toughening agent, and a stabilizer to prepare a mixture;

[0036] S3: In the laser sintering 3D printer, use the computer to design the three-dimensional file of the film, in which the design aperture is 0.1-0.3nm, the printing la...

Embodiment 1

[0039] A filter membrane for treating volatile organic compounds, which comprises the following raw materials in parts by weight: 60 parts of feldspar, 40 parts of quartz, 15 parts of sodium silicate, 20 parts of activated carbon, 12 parts of zeolite, and 10 parts of diatomaceous earth , 8 parts of carbon fiber, 2.6 parts of glass fiber, 0.5 part of catalyst, 0.78 part of crosslinking agent, 0.4 part of tackifier, 1.2 parts of plasticizer, 1.3 parts of toughening agent, 0.5 part of stabilizer;

[0040] The catalyst comprises stannous octoate;

[0041] Described linking agent is dicumyl peroxide;

[0042] Described tackifier is propyltrimethoxysilane;

[0043] Described plasticizer is citric acid ester;

[0044] Described toughening agent is polypropylene adiene rubber;

[0045] The stabilizer is an organotin stabilizer;

[0046] The preparation method of the filter membrane for filtering and absorbing volatile organic compounds comprises the following steps:

[0047] S1: ...

Embodiment 2

[0051] A filter membrane for treating volatile organic compounds, which comprises the following raw materials in parts by weight: 40 parts of feldspar, 30 parts of quartz, 10 parts of sodium silicate, 16 parts of activated carbon, 10 parts of zeolite, and 8 parts of diatomite , 6 parts of carbon fiber, 2 parts of glass fiber, 0.4 part of catalyst, 0.5 part of crosslinking agent, 0.3 part of tackifier, 0.8 part of plasticizer, 0.9 part of toughening agent, and 0.4 part of stabilizer;

[0052] The catalyst comprises stannous octoate;

[0053] Described linking agent is dicumyl peroxide;

[0054] Described tackifier is propyltrimethoxysilane;

[0055] Described plasticizer is citric acid ester;

[0056] Described toughening agent is polypropylene adiene rubber;

[0057] The stabilizer is an organotin stabilizer;

[0058] The preparation method of the filter membrane for controlling volatile organic compounds, comprises the following steps:

[0059] S1: Soak feldspar, quartz, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com