High temperature-resisting fluid loss agent for drilling fluid and preparation method thereof

A water loss reducing agent and anti-high temperature technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of thick mud cake, easy increase of friction resistance, high relative molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

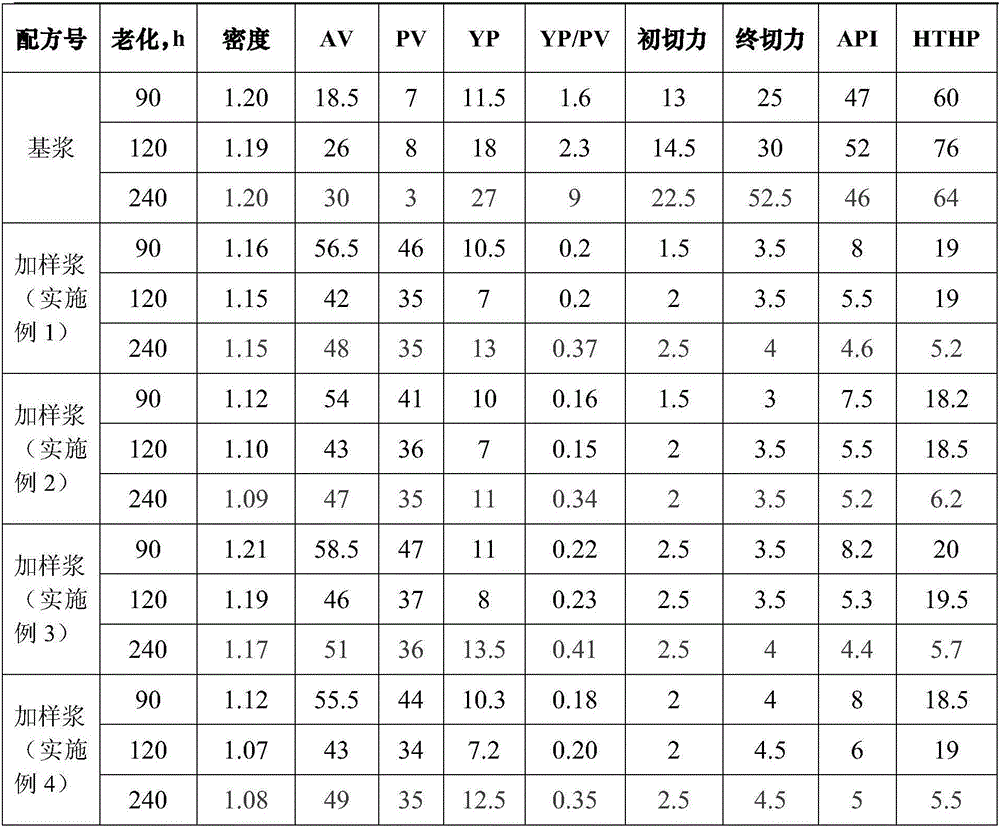

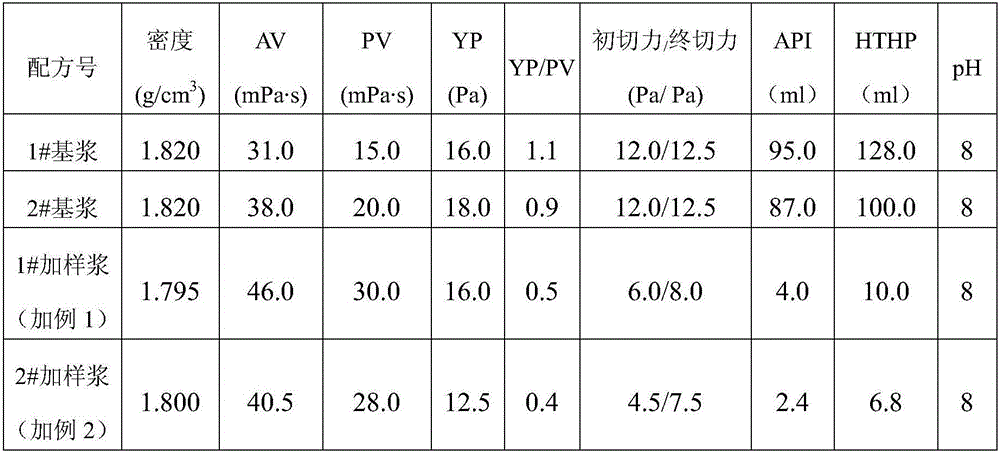

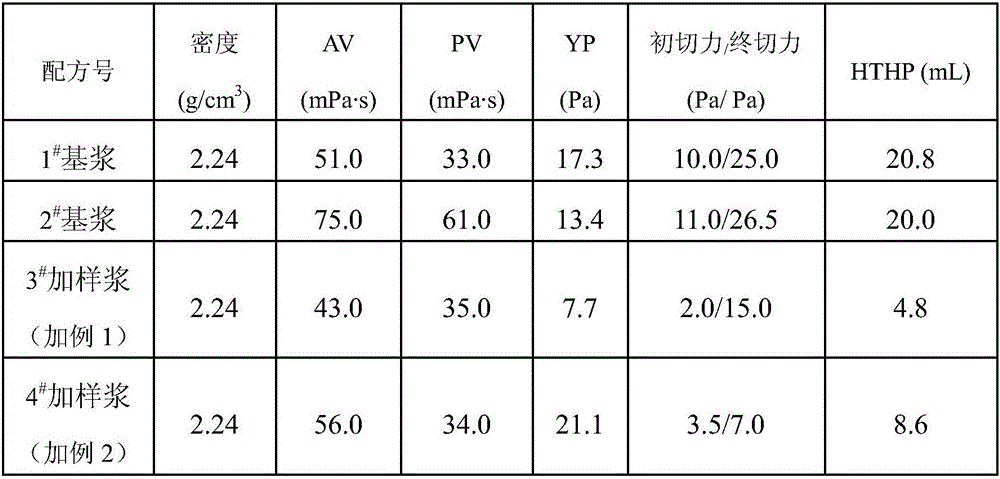

Embodiment 1

[0024] Embodiment 1: prepare each raw material according to the composition ratio: rosin acid 10%; glycerol 8%; sulfonated pitch 30%; cationic starch 10%; temporary plugging agent 10%; high temperature stabilizer 12%; Among them, the cationic starch is composed of starch tertiary amino alkyl ether and quaternary ammonium starch ether at a ratio of 1:1.5, the high temperature stabilizer is composed of sulfonated phenolic resin and sulfonated lignite resin at a ratio of 1:1, and the temporary blocking agent is composed of tertiary ammonium starch ether Butylphenolic vulcanization resin, octylphenolic vulcanization resin, and calcium carbonate are composed according to the ratio of 8:10:5, and the oxygen scavenger is sodium sulfite. Add glycerol to rosin acid, and stir at 170°C for 2 hours, then esterification reaction occurs; then add sulfonated asphalt, cationic starch, temporary plugging agent, high temperature stabilizer, oxygen scavenger, at 120°C Stir and mix, and after 3 h...

Embodiment 2

[0025] Embodiment 2: prepare each raw material according to the component distribution ratio: rosin acid 15%; glycerol 12%; sulfonated pitch 40%; cationic starch 12%; temporary plugging agent 20%; high temperature stabilizer 14%; Cationic starch is composed of starch tertiary amino alkyl ether and quaternary ammonium starch ether at a ratio of 1:1.5, the high temperature stabilizer is composed of sulfonated phenolic resin and sulfonated lignite resin at a ratio of 1:1, and the temporary plugging agent is composed of tertiary ammonium starch ether Butylphenolic vulcanization resin, octylphenolic vulcanization resin, and calcium carbonate are composed according to the ratio of 8:10:5, and the oxygen scavenger is sodium sulfite. Add glycerol to rosin acid, and stir at 190°C for 2 hours, then esterification reaction occurs; then add sulfonated asphalt, cationic starch, temporary plugging agent, high temperature stabilizer, oxygen scavenger, Stir and mix, and after 4 hours, a high-...

Embodiment 3

[0026] Embodiment 3: prepare each raw material according to the composition ratio: rosin acid 12%; glycerol 10%; sulfonated pitch 35%; cationic starch 10%; temporary plugging agent 15%; high temperature stabilizer 13%; Among them, the cationic starch is composed of starch tertiary amino alkyl ether and quaternary ammonium starch ether according to 1:1.5, the high temperature stabilizer is composed of sulfonated phenolic resin and sulfonated lignite resin according to 1:1, and the temporary plugging agent is composed of tertiary Butylphenolic vulcanization resin, octylphenolic vulcanization resin, and calcium carbonate are composed according to the ratio of 8:10:5, and the oxygen scavenger is sodium sulfite. Add glycerol to rosin acid, and stir at 180°C for 2 hours, then esterification reaction occurs; then add sulfonated asphalt, cationic starch, temporary plugging agent, high temperature stabilizer, oxygen scavenger, Stir and mix, and after 3 hours, a high-temperature anti-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com