Stabilizer for drilling fluids and preparation method thereof

A stabilizer and drilling fluid technology, applied in the field of drilling, can solve the problems of complex formation pressure system, long open hole in deep well drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

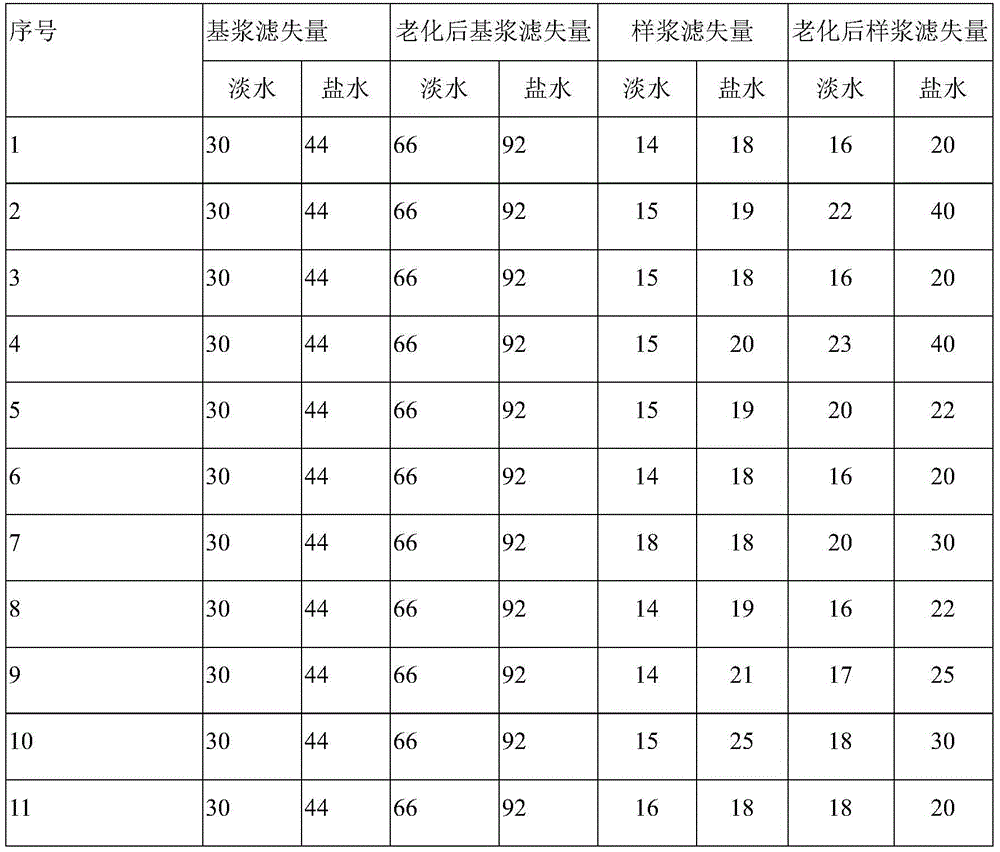

[0039] Get 25 parts by weight of sulfonated lignite resin, 50 parts by weight of sulfonated phenolic resin, 14 parts by weight of high-strength polypropylene fiber, 6 parts by weight of polyethylene glycol, 5 parts by weight of acetone oxime, in the reactor (double helix cone mixer , DSH model, 60 rev / min) and stirred for 1 hour, dried and packaged, the "stabilizer for drilling fluid" can be prepared. Then, under the conditions of fresh water and salt water, the fluid loss of the base slurry, the fluid loss of the base slurry after aging, the fluid loss of the sample slurry, and the fluid loss of the sample slurry after aging were measured. The results are shown in Table 2 below.

Embodiment 2

[0041] Get 25 parts by weight of sulfonated lignite resin, 50 parts by weight of sulfonated phenolic resin, 14 parts by weight of high-strength polypropylene fiber, 6 parts by weight of polyethylene glycol and 1 part by weight of acetone oxime, in the reactor (double helix conical mixer , DSH model, 60 rev / min) and stirred for 1 hour, dried and packaged, the "stabilizer for drilling fluid" can be prepared. Then, the same method as in Example 1 was used to measure the fluid loss of the base slurry, the fluid loss of the base slurry after aging, the fluid loss of the sample slurry, and the fluid loss of the sample slurry after aging. The results are shown in Table 2 below.

Embodiment 3

[0043] Get 25 parts by weight of sulfonated lignite resin, 50 parts by weight of sulfonated phenolic resin, 14 parts by weight of high-strength polypropylene fiber, 6 parts by weight of polyethylene glycol and 10 parts by weight of acetone oxime, in the reactor (double helix cone mixer , DSH model, 60 rev / min) and stirred for 1 hour, dried and packaged, the "stabilizer for drilling fluid" can be prepared. Then, the same method as in Example 1 was used to measure the fluid loss of the base slurry, the fluid loss of the base slurry after aging, the fluid loss of the sample slurry, and the fluid loss of the sample slurry after aging. The results are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com