Preparation method of acid dye color fixing agent

A technology of acid dyes and color-fixing agents, applied in dyeing, textiles and papermaking, etc., can solve the problems of low dyeing rate of reactive dyes, troublesome production, pungent acetic acid smell of color-fixing agents, etc., and achieves easy adjustment and Control, easy adjustment and control, excellent color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of an acid dye fixing agent, specifically comprising the following steps:

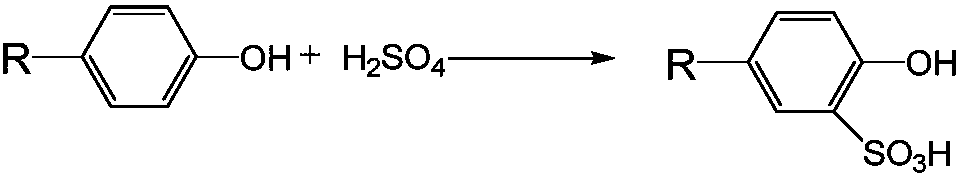

[0030] a. Synthesis of sulfonated phenols: Add metered phenols and concentrated sulfuric acid into a reaction kettle with a stirrer, reflux condenser and thermometer, stir and heat to 110-140°C, and keep warm for 2-3 hours to obtain Brown-red sulfonated phenols, cooled to room temperature, and left to stand for use;

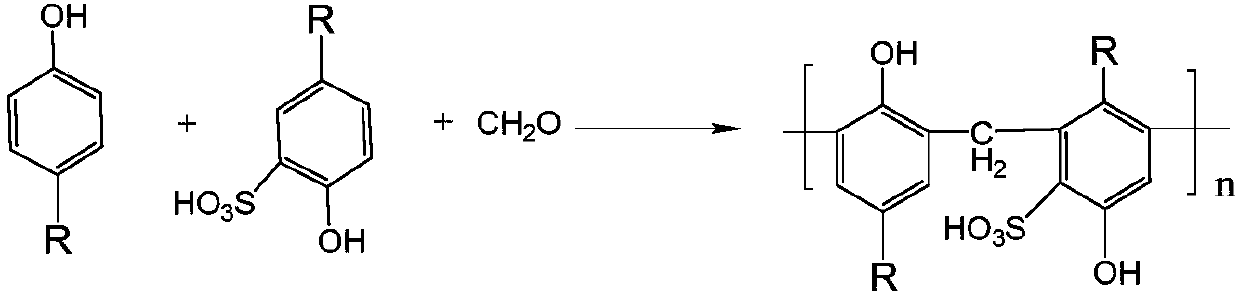

[0031] b, pre-condensed part of phenols: add metered phenols and organic solvent to another reaction kettle with stirrer, reflux condenser and thermometer, stir until completely dissolved and then add metered concentration of 37wt% formaldehyde solution and concentrated sulfuric acid, heat up to 90-100°C, keep warm for 2-3 hours, and cool down to 70-80°C;

[0032] c. Polycondensation color-fixing agent: add the product of step b into the reaction kettle of step a, stir and heat up (there may be solid precipitation at this time), as the reaction progresses, the...

Embodiment 1

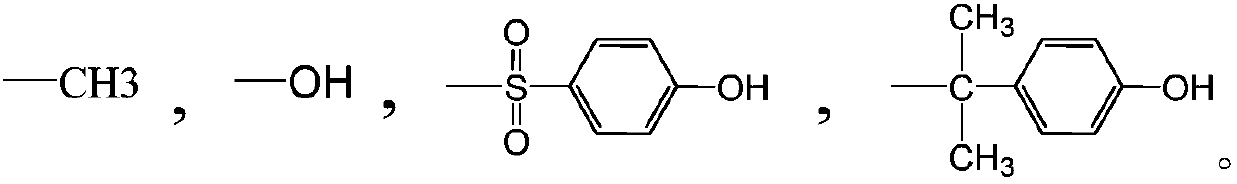

[0035] Add 250g of bisphenol S and 200g of concentrated sulfuric acid into a 2L reaction kettle equipped with a stirrer, reflux condenser and thermometer, heat to 125°C while stirring, keep warm for 3.5 hours to obtain sulfonated bisphenol S, cool to room temperature, and statically put aside;

[0036] Add 140g of bisphenol S and 280g of n-butanol into another 1L reaction kettle with agitator, reflux condenser and thermometer, stir to make it dissolve completely, then add 110g of 37% formaldehyde solution and 20g of concentrated sulfuric acid, and heat up to 100 ℃, keep warm for 2 hours, then cool down to 80℃;

[0037] Pour the product in the second step into the reaction kettle of the first step, stir and heat up (solids will precipitate out at this time), as the reaction progresses, the system gradually becomes transparent and the viscosity increases slowly, keeping the final temperature at 100 React at -105°C for 6 hours, cool down and discharge.

Embodiment 2

[0039] Add 250g of bisphenol S and 200g of concentrated sulfuric acid into a 2L reaction kettle equipped with a stirrer, reflux condenser and thermometer, heat to 120°C while stirring, keep warm for 3 hours to obtain sulfonated bisphenol S, cool to room temperature, and statically put aside;

[0040] Add 160g of bisphenol S and 300g of n-butanol into another 1L reaction kettle with a stirrer, reflux condenser and thermometer, stir to make it completely dissolve, then add 120g of 37% formaldehyde solution and 20g of concentrated sulfuric acid, and heat up to 100 ℃, keep warm for 2 hours, then cool down to 80℃;

[0041] Pour the product in the second step into the reaction kettle of the first step, stir and heat up (solids will precipitate out at this time), as the reaction progresses, the system gradually becomes transparent and the viscosity increases slowly, keeping the final temperature at 100 React at -105°C for 5 hours, cool down and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com