Preparation method of sulfonated phenolic water-absorbing resin

A technology of water-absorbent resin and sulfonated phenolic resin, which is applied in the field of synthetic polymer water-absorbent resin, can solve problems such as insufficient high-temperature resistance, and achieve good viscoelasticity, compressive strength, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

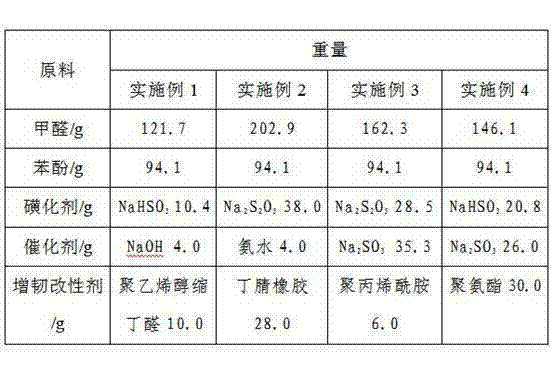

[0006] Add formaldehyde into the reactor equipped with reflux condenser, thermometer and stirrer, then add molten phenol, after stirring evenly, add sulfonating agent, after it is completely dissolved, add catalyst and appropriate amount of water, the reaction temperature is controlled at 50 -60°C, after stirring for 0.5h, the temperature was raised to 100°C, after 1h of reaction, toughening modifier was added, and the reaction was continued for 1-2h. Viscoelastic water-absorbent resin.

[0007] See the following list for specific implementation methods:

[0008]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com