Method for preparing moisture holding and restoring lotion

A technology for repairing liquid and filtrate, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve problems such as skin irritation and poor water retention, and achieve the purpose of preventing bacterial infection, increasing absorption, and promoting repair. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

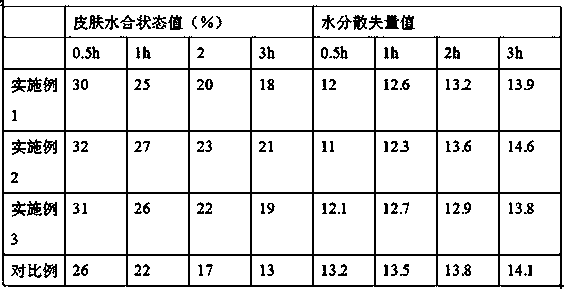

Examples

preparation example Construction

[0029] Preparation method of additive solution:

[0030] A. Mix the mixed plants and 0.3mol / L hydrochloric acid solution in a mass ratio of 4-6:10, soak for 2h, take out the soaked plants, dry, crush, collect the crushed material, and combine the crushed material with 0.5mol / L ethanol solution Mix according to the mass ratio of 1:3~5, perform steam explosion, set the pressure to 1.8MPa, maintain the pressure for 30s, and collect the steam explosion;

[0031] B. Mix the steam explosion material and the solvent according to the mass ratio of 1:3~5, cook for 3h, filter, collect the filtrate, mix the filtrate and the decoloring agent according to the mass ratio of 7:3~5, collect the decolorizing liquid, and concentrate to decolorize 60% of the volume of the liquid, the concentrated liquid and the surfactant are mixed in a mass ratio of 7-9:1 to obtain an additive liquid.

[0032] The mixed plant is a mixture of motherwort and lobelia in a mass ratio of 4-6:5.

[0033] The solvent is made...

Embodiment 1

[0042] The mixed enzyme is a mixture of pepsin and papain at a mass ratio of 6:5.

[0043] The additives are chitosan and urea mixed with a mass ratio of 9:8.

[0044] The auxiliary agent is a mixture of polyglutamic acid and genipin at a mass ratio of 7:1.

[0045] The auxiliary agent is a mixture of Azone and Lanolin in a mass ratio of 2:7.

[0046] Preparation method of additive solution:

[0047] A. Mix the mixed plants and 0.3mol / L hydrochloric acid solution at a mass ratio of 4:10, soak for 2h, take out the soaked plants, dry, crush, collect the crushed material, and mix the crushed material with 0.5mol / L ethanol solution according to mass Mix the ratio 1:3, perform steam explosion, set the pressure to 1.8MPa, maintain the pressure for 30s, and collect the steam explosion;

[0048] B. Mix the steam explosion material and the solvent at a mass ratio of 1:3, cook for 3 hours, filter, collect the filtrate, mix the filtrate and the decolorizing agent at a mass ratio of 7:3 to decolor,...

Embodiment 2

[0059] The mixed enzyme is a mixture of pepsin and papain in a mass ratio of 5:4.

[0060] The additives are chitosan and urea mixed with a mass ratio of 8:8.

[0061] The auxiliary agent is a mixture of polyglutamic acid and genipin at a mass ratio of 7:1.

[0062] The auxiliary agent is a mixture of Azone and Lanolin in a mass ratio of 2:6.

[0063] Preparation method of additive solution:

[0064] A. Mix the mixed plants and 0.3mol / L hydrochloric acid solution at a mass ratio of 5:10, soak for 2h, take out the soaked plants, dry, crush, collect the crushed material, and mix the crushed material with 0.5mol / L ethanol solution according to mass Mix with a ratio of 1:4, perform steam explosion, set the pressure to 1.8MPa, maintain the pressure for 30s, and collect the steam explosion;

[0065] B. Mix the steam explosion material and the solvent according to the mass ratio of 1:4, cook for 3 hours, filter, collect the filtrate, mix the filtrate and the decolorizer according to the mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com