Preparation method for sulfonated-phenol-formaldehyde resin formed by modifying benzoxazine resin

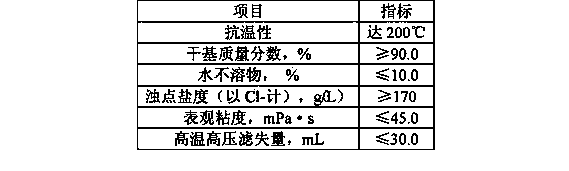

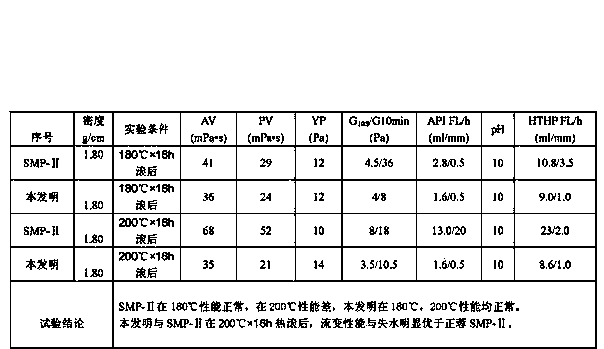

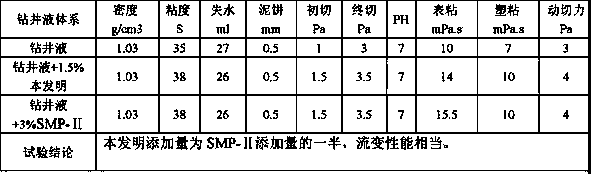

A technology of sulfomethyl phenolic resin and sulfonated phenolic resin, which is applied in the field of preparation of super-concentrated new sulfomethyl phenolic resin SMP-Ⅲ, can solve the problems of not meeting the operation requirements, large amount of addition, high drilling cost, etc. Achieve the effects of good filtration loss, low filtration loss and strong salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A kind of preparation method of sulfomethylphenol-formaldehyde resin modified with benzoxazine resin is as follows:

[0016] (1) Preparation of powder: Grind bisphenol A benzoxazine with a particle size of ≤25mm into a powder with a particle size of 10um-125um for later use;

[0017] (2) Preparation of modified sulfonated phenolic resin agent:

[0018] ① Add 1 mole of phenol and 1 mole of formaldehyde into the reaction kettle with a reflux cooler equipped with a stirrer in sequence, stir at 119°C for 10 minutes, cool down, keep the temperature at 109°C, then add 1 mole of formaldehyde, 0.5 mole of sodium metabisulfite, water 40ml is used as a sulfonating agent, the sulfonating time is 3 hours, and finally 1 mole of formaldehyde is added, and the reaction is refluxed at 97°C-104°C for 3-4 hours;

[0019] ②When the reaction is finished, cool down to 60°C-70°C and discharge to obtain the modified sulfonated phenolic resin agent.

[0020] (3) Put the powder obtained in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com