Multi-flue closed connecting bridge pipe for clean coke oven

A closed and clean technology, applied in the field of riser pipes, can solve the problems that the coke cake cannot be uniformly matured, the flow rate adjustment of high temperature liquid cannot be realized, and the temperature drops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

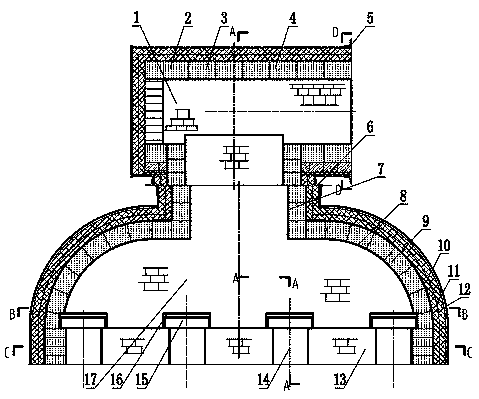

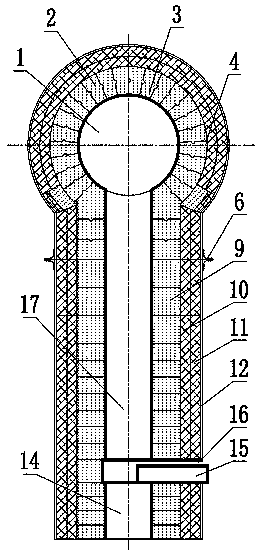

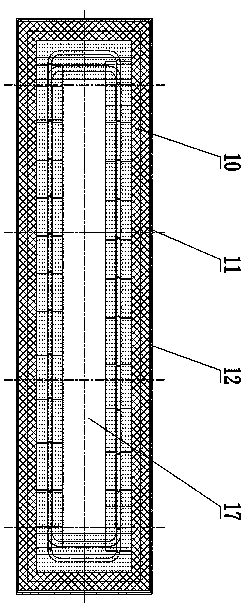

[0021] Such as figure 1 , figure 2 As shown in the clean coke oven multi-flue closed connecting bridge tube, the riser casing 12 of the riser is made of thin steel plates, and the riser includes a riser connection section 7 and a riser diversion section 8, and the riser connection section 7 and the pipe wall of the riser diversion section 8 adopt the same structure, and the pipe walls of the two sections are the riser masonry layer 9, the riser fire-resistant insulation board layer 10, and the riser fire-resistant insulation fiber layer from the inside to the outside. 11 and riser shell 12. The riser masonry layer 9 is made of erosion-resistant mullite bricks, the riser fire-resistant insulation board layer 10 is laid with aluminum silicate fiber board, and the riser pipe fire-resistant insulation fiber layer 11 is filled with aluminum silicate fiber blanket , the fire-resistant and heat-insulating fiber layer can also be a zirconium-containing fiber layer or a calcium sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com