Structure support system for ultrahigh one-storied factory

A technology of structural support and system, applied in building components, building structure, earthquake resistance, etc., can solve the problems of limitation, span change, unable to provide safe and reliable support, etc., to achieve strong collapse resistance, reasonable structure, ensure shear The effect of force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

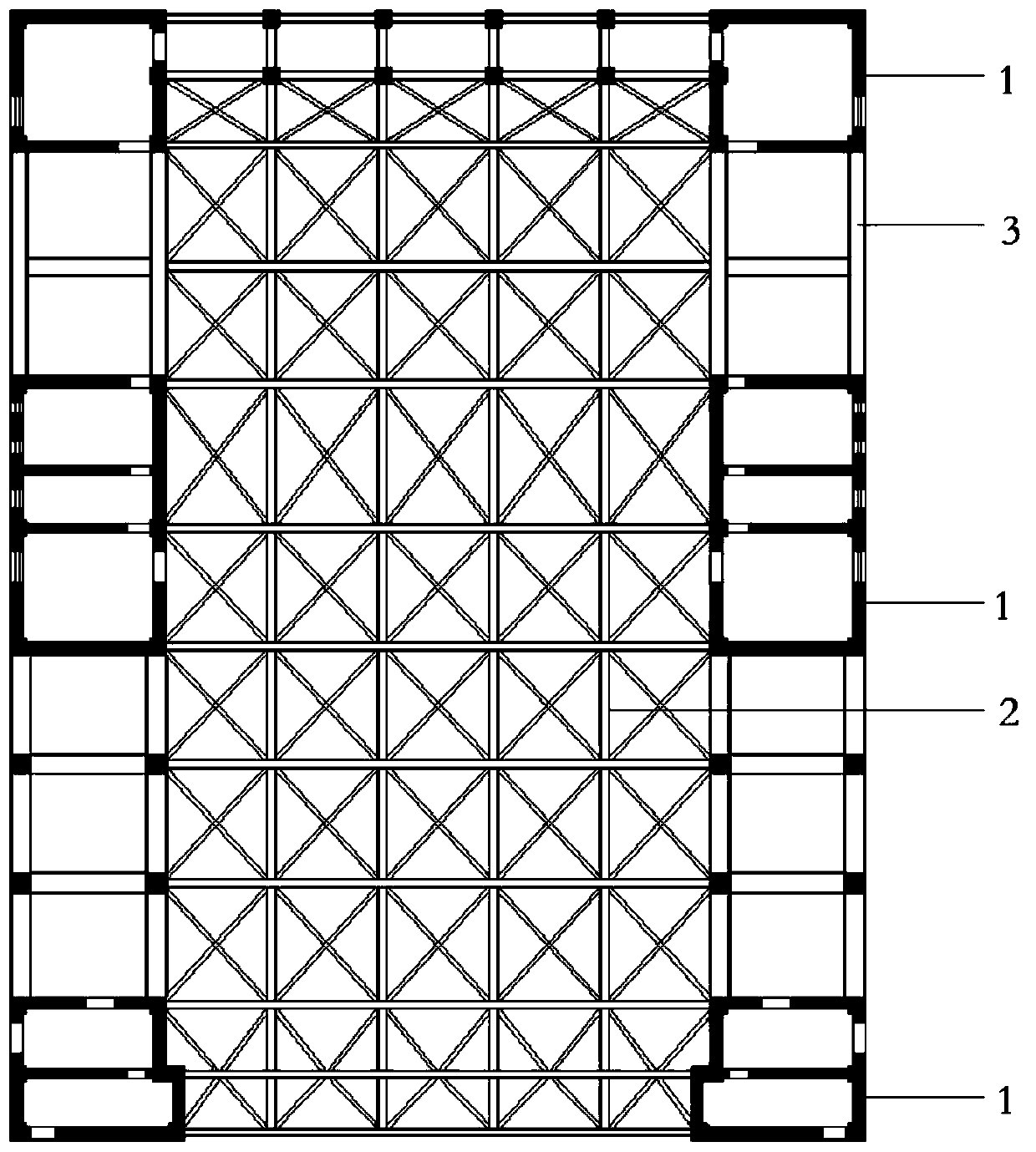

[0019] as attached figure 1 As shown, the present invention provides a structural support system for a super-high single-storey factory building, which includes a plurality of concrete cylinders 1, a roof steel truss 2 and a plurality of frame beams 3; the concrete cylinder 1 in a rectangular structure Vertically fixed on the ground base, the concrete cylinders 1 are arranged in a straight line in the longitudinal direction and symmetrically distributed on the plane. The top of the concrete cylinders 1 is connected into one by the roof steel trusses 2. The frame beams 3 are fixedly connected to form an overall structural support system.

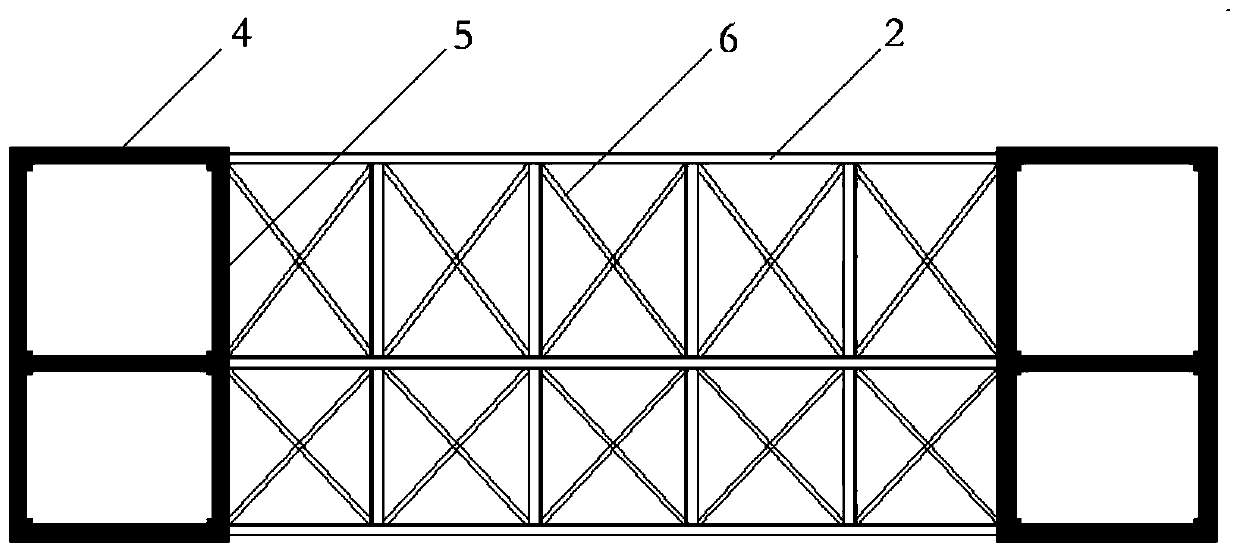

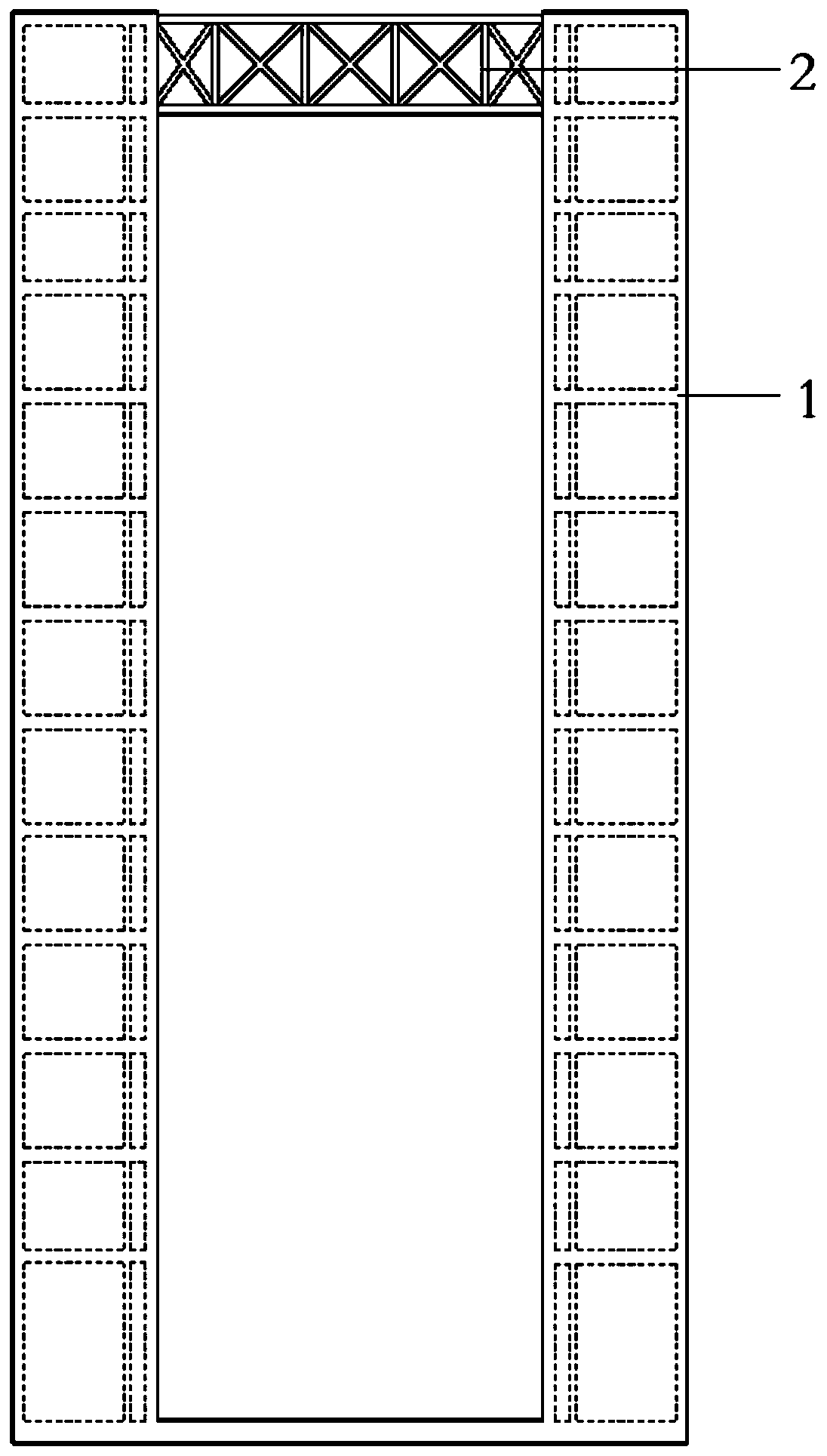

[0020] as attached figure 2 As shown, the concrete cylinder 1 is composed of two horizontal walls 4 and two vertical walls 5, as attached image 3 As shown, the roof steel truss 2 is divided into upper, middle and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com