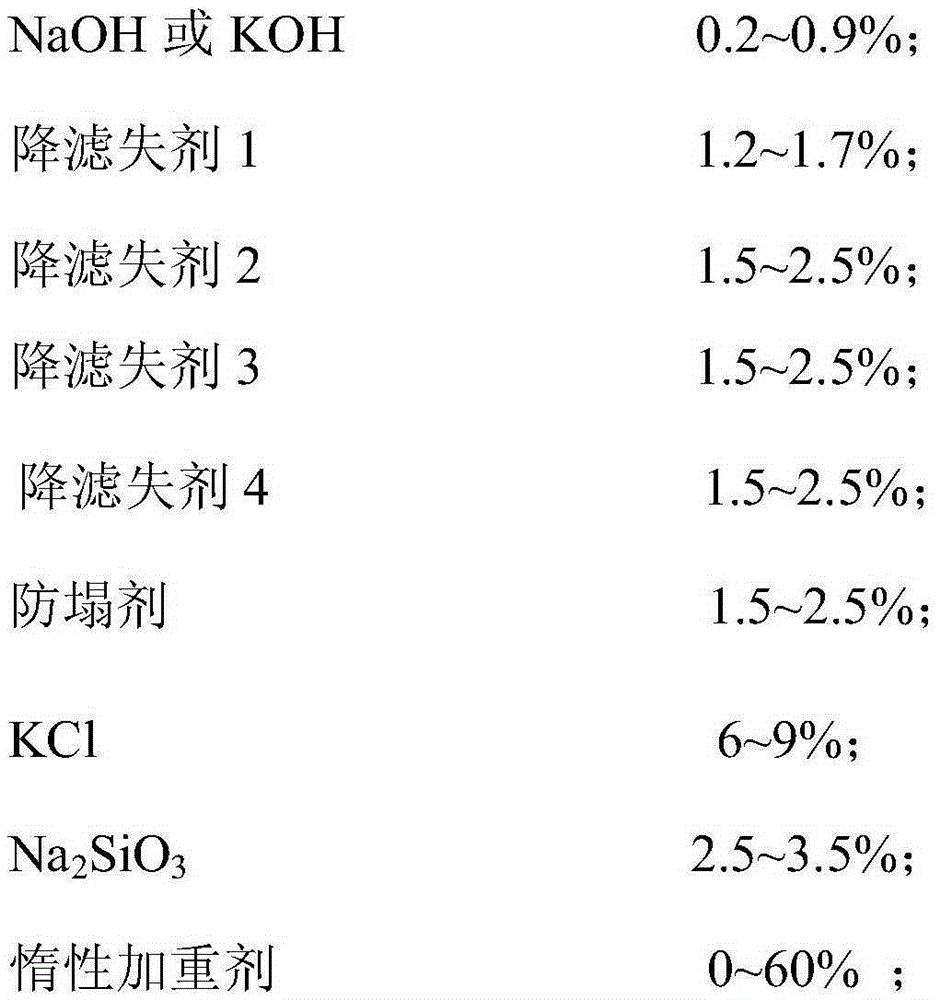

na2sio3-kcl anti-collapse drilling fluid and preparation method thereof

A technology of drilling fluid and anti-slump agent, which is applied in the field of oil drilling, can solve the problems that affect the smooth progress of drilling operations and logging, the increase of drilling costs, and the extension of construction period, so as to solve the technical problems of preventing mud and shale collapse and achieve significant economic benefits , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

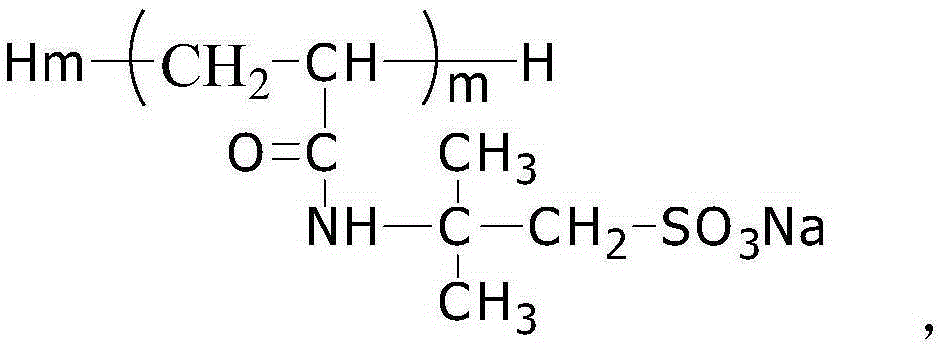

Method used

Image

Examples

Embodiment 1

[0033] 1) Add bentonite to water at a concentration of 32g / l, and add 0.2% Na 2 CO 3 , and pre-hydrated for 24 hours under stirring conditions to obtain bentonite slurry;

[0034] 2) adding 0.5wt% KOH to the bentonite slurry to adjust its pH=9.5;

[0035] 3) Add Redu1 type fluid loss control agent produced by Beijing Peikang Jiaye Technology Development Co., Ltd., which accounts for 1.7% of the bentonite slurry mass into the slurry finally obtained in step 2);

[0036] 4) Add LHJS-3 type fluid loss reducer produced by Shandong Luhai Drilling Technology Co., Ltd., produced by Qingdao Sanli Chemical Technology Co., Ltd., which all account for 2% of the bentonite slurry mass into the slurry finally obtained in step 3). The FD-1 type fluid loss reducer and the KJAN type fluid loss reducer produced by Shijiazhuang Hualai Dingsheng Technology Co., Ltd.; stir for 10 minutes;

[0037] 5) Add NFA-25 anti-slump agent produced by Beijing Peikang Jiaye Technology Development Co., Ltd.,...

Embodiment 2

[0047] 1) Add bentonite to water at a concentration of 20g / l, and add 0.12% Na 2 CO 3 , and pre-hydrated for 24 hours under stirring conditions to obtain bentonite slurry;

[0048] 2) Add 0.6wt% NaOH to the bentonite slurry to adjust its pH=11.5;

[0049]3) Add Redu1 type fluid loss control agent produced by Beijing Peikang Jiaye Technology Development Co., Ltd., which accounts for 1.2% of the bentonite slurry mass into the slurry finally obtained in step 2);

[0050] 4) Add LHJS-3 type fluid loss control agent produced by Shandong Luhai Drilling Technology Co., Ltd., produced by Qingdao Sanli Chemical Technology Co., Ltd., which all account for 2.5% of the bentonite slurry mass into the slurry finally obtained in step 3). The FD-1 type fluid loss reducer and the KJAN type fluid loss reducer produced by Shijiazhuang Hualai Dingsheng Technology Co., Ltd.; stir for 15 minutes;

[0051] 5) Add NFA-25 anti-slumping agent produced by Beijing Peikang Jiaye Technology Development ...

Embodiment 3

[0060] 1) Add bentonite to water at a concentration of 26g / l, and add 0.15% Na 2 CO 3 , and pre-hydrated for 24 hours under stirring conditions to obtain bentonite slurry;

[0061] 2) Add 0.5wt% NaOH to the bentonite slurry to adjust its pH=13.7;

[0062] 3) Add Redu1 type fluid loss control agent produced by Beijing Peikang Jiaye Technology Development Co., Ltd., which accounts for 1.5% of the bentonite slurry mass into the slurry finally obtained in step 2);

[0063] 4) Add LHJS-3 type fluid loss control agent produced by Shandong Luhai Drilling Technology Co., Ltd., produced by Qingdao Sanli Chemical Technology Co., Ltd., which all account for 2.2% of the bentonite slurry mass into the slurry finally obtained in step 3). The FD-1 type fluid loss reducer and the KJAN type fluid loss reducer produced by Shijiazhuang Hualai Dingsheng Technology Co., Ltd.; stir for 12 minutes;

[0064] 5) Add NFA-25 anti-slumping agent produced by Beijing Peikang Jiaye Technology Development...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com