Environment-friendly chlorine-free drilling fluid and preparation method thereof

A chlorine-free drilling fluid technology, applied in the field of drilling fluid, can solve the problems of failing to meet sewage discharge standards, plants not growing, polluting groundwater, etc., achieving low pumping and exciting pressure, saving drilling cycle, and strong inhibition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An environment-friendly chlorine-free drilling fluid is characterized in that it is composed according to the mass ratio of the following components:

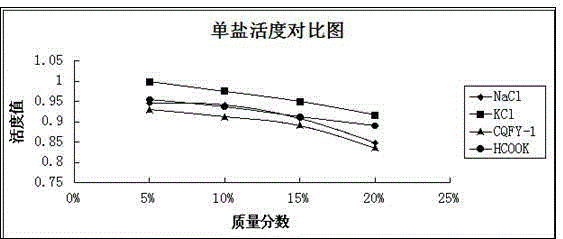

[0040] Chlorine-free strong inhibitory compound salt, 8-18%, function: no chlorine, good environmental protection, improve the environmental protection of the system, increase the density, improve the chemical inhibition and anti-slump effect of drilling fluid, form a film on the well wall and reduce the drilling fluid activity;

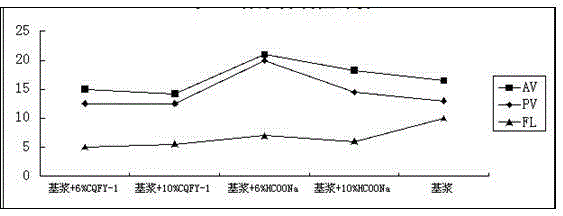

[0041] Drilling fluid viscosity raising agent, 0.2-0.3%, function: increase drilling fluid viscosity and improve sand-carrying ability;

[0042] Water-dispersed cationic emulsified asphalt powder, 1.5-3%, function: form a hard and smooth mud cake, with good plugging ability above the softening point;

[0043] Anti-salt and anti-calcium fluid loss reducer, 0.2-0.4%, function: easy to degrade, good environmental protection, sticky, wall protection, forming smooth and dense mud cake;

[0044] Na...

Embodiment 2

[0055] What the chlorine-free strong inhibitory compound salt that used in the present embodiment adopted is the model that the Xi'an Changqing chemical industry produces is the chlorine-free strong inhibitory compound salt of CQFY-1;

[0056] The drilling fluid viscosity raising agent is the model PAC-HV drilling fluid viscosity raising agent produced by Xi'an Changqing Chemical Industry Co., Ltd.;

[0057] The water-dispersed cationic emulsified asphalt powder adopts the water-dispersed cationic emulsified asphalt powder of the model SFT-1 produced by Henan Jinma;

[0058] The anti-salt and anti-calcium fluid loss additive is JT-1 anti-salt and anti-calcium fluid loss additive produced by Henan Jinma;

[0059] The natural fluid loss control agent is the natural polymer fluid loss control agent of the model NAT-20 produced by Beijing Peikang;

[0060] The acid-soluble temporary plugging reservoir protection agent adopts the acid-soluble temporary plugging reservoir protectio...

Embodiment 3

[0096] A preparation method of chlorine-free drilling fluid, carried out according to the following steps:

[0097] Step 1. After spud drilling, add carboxymethyl cellulose sodium salt with a mass ratio of 0.2%, oxidized bitumen with a mass ratio of 3%, carboxymethyl starch with a mass ratio of 0.4%, and A mixture of 0.2% safflower gum, 4% ultrafine calcium and limestone, cyclically drilled for 8 hours;

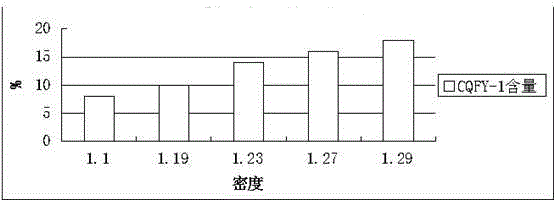

[0098] Step 2, adding a mixture of potassium formate and sodium formate and 0.1% caustic soda NaOH with a mass ratio of 8% in the wellbore of step 1, and continue drilling;

[0099] Step 3: Continue to add the mixture of potassium formate and sodium formate into the wellbore during the drilling process. When the well deviation is 30°, the density of the drilling fluid reaches 1.15g / cm 3 ;

[0100] Step 4: Continue drilling until the well deviation is 45° and the density of the drilling fluid is 1.25g / cm 3 , the mass ratio of the mixture of potassium formate and sodium form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com