Reinforcing method for shield receiving tunnel portal

A receiving hole and shield technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of long construction period and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

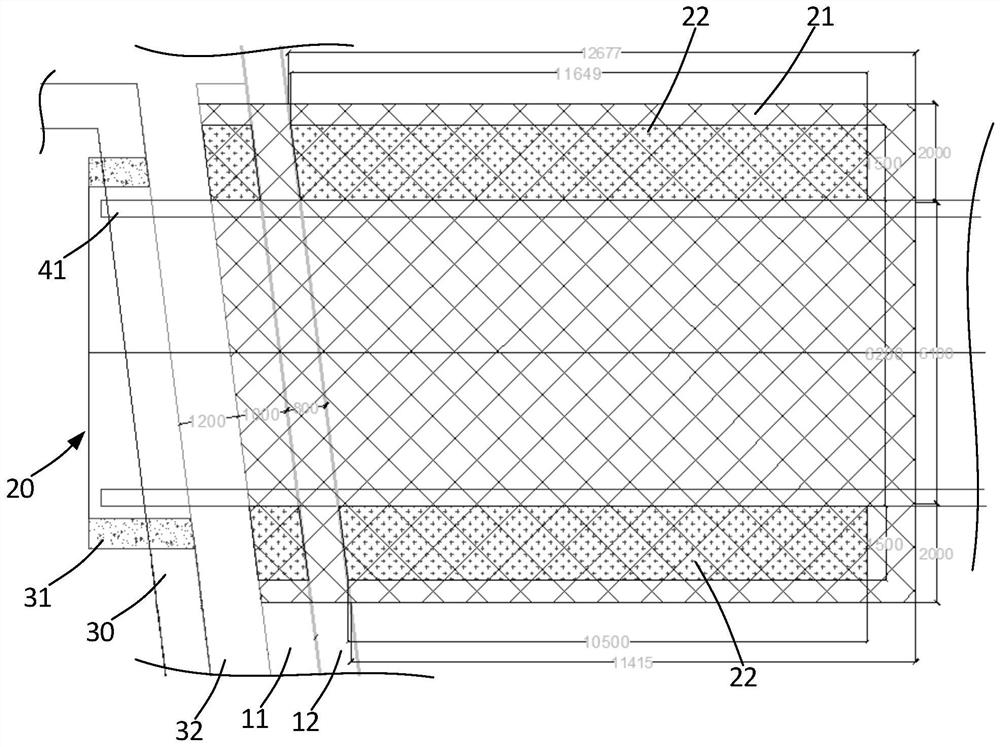

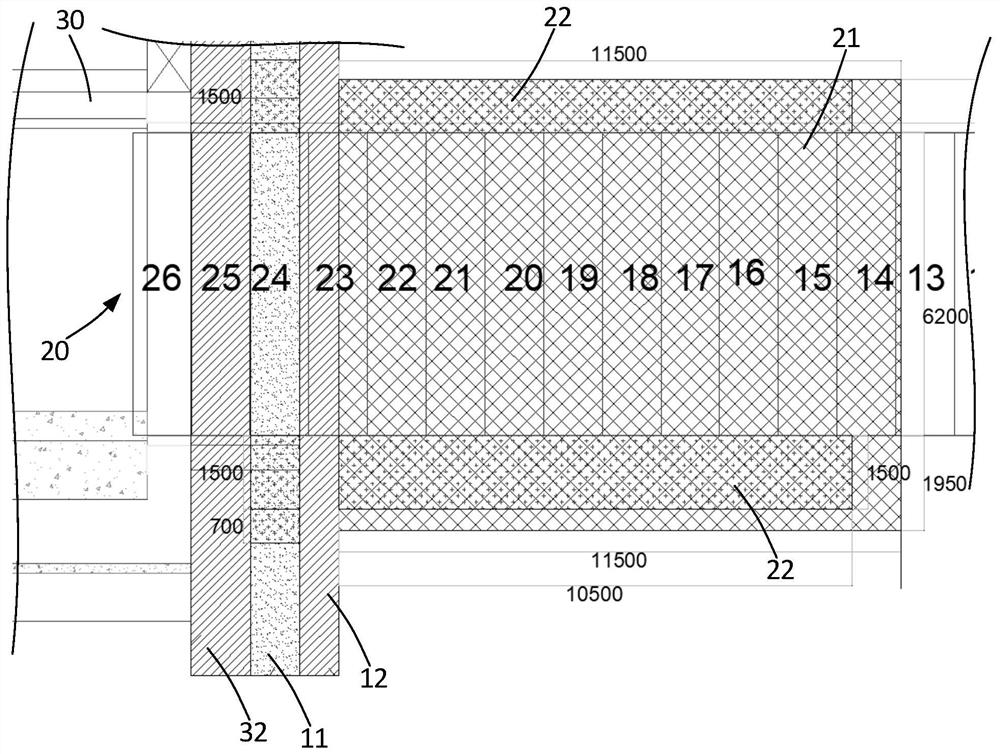

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

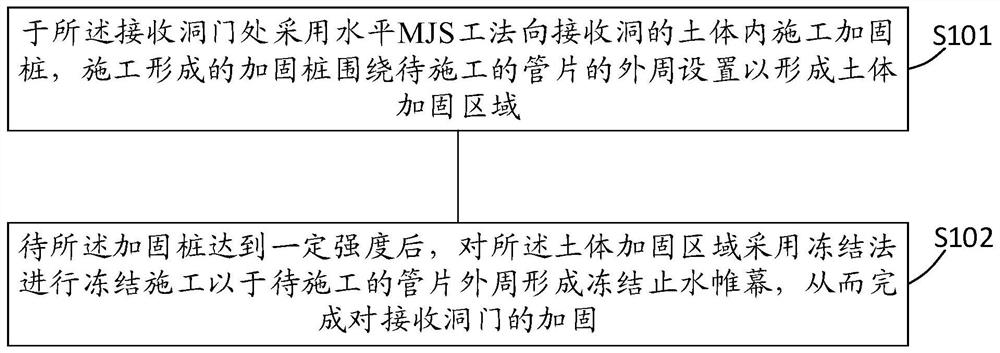

[0023] refer to figure 1 , the present invention provides a reinforcement method for the receiving portal of the shield machine, which is used for the reinforcement of the construction area where it is difficult to implement the vertical cement system reinforcement method. The combination of the horizontal MJS construction method and the horizontal freezing construction method solves the problem of full-section MJS horizontal reinforcement. The problem of cost supply and long construction period. The horizontal MJS construction method adopts the form of hollowing out in the middle of the outer ring reinforcement, that is, a ring shape, which greatly improves the workload and construction period, and saves nearly half of the cost compared with full-section reinforcement. The MJS construction method has high reinforcement strength, but when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com