Method for preparing rapid-dry corn starch adhesive

A technology of corn starch and adhesives, applied in the direction of starch adhesives, adhesive types, etc., can solve the problems of not being suitable for small-scale production, pollution of packaging contents, large amount of oxidant, etc., and achieve excellent bonding strength, Reduced dosage, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

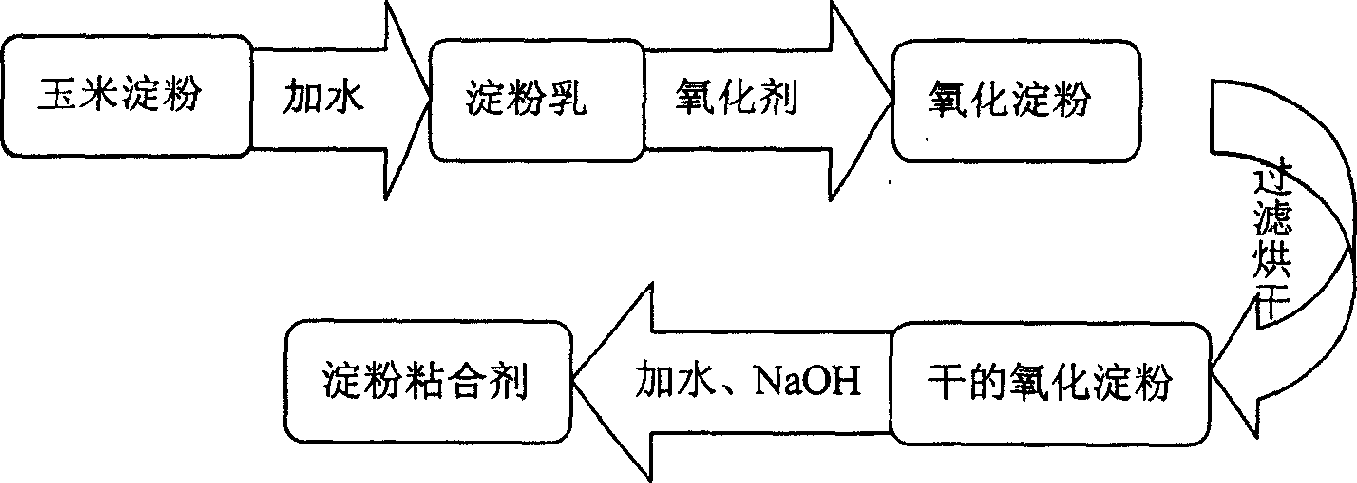

[0016] According to the technical scheme of the present invention, the preparation method of producing low-cost quick-drying type cornstarch adhesive comprises the following main contents:

[0017] 1> Add tap water to the reaction kettle according to 1.5 times the mass fraction of dry starch and stir to make starch milk, the concentration of starch milk: 40%;

[0018] 2> Catalyst and its dosage: choose Fe 2+ salt, the main choice is FeSO 4 , FeCl 2 etc., the dosage is 0.25% to 0.35% of the dry starch mass fraction;

[0019] 3> Oxidant and its dosage: choose H 2 o 2 , the dosage is about 5% (4.5-6%) of the dry starch mass fraction;

[0020] 4> Oxidation temperature: 55℃~60℃;

[0021] 5> Oxidation time: After the temperature rises to 58°C, add an oxidant and react for 10 minutes, then add a catalyst and react for another 25 to 30 minutes;

[0022] 6>Drying temperature: no more than 60°C;

[0023] 7> Moisture content of oxidized starch after drying: 15% by mass for long-t...

Embodiment

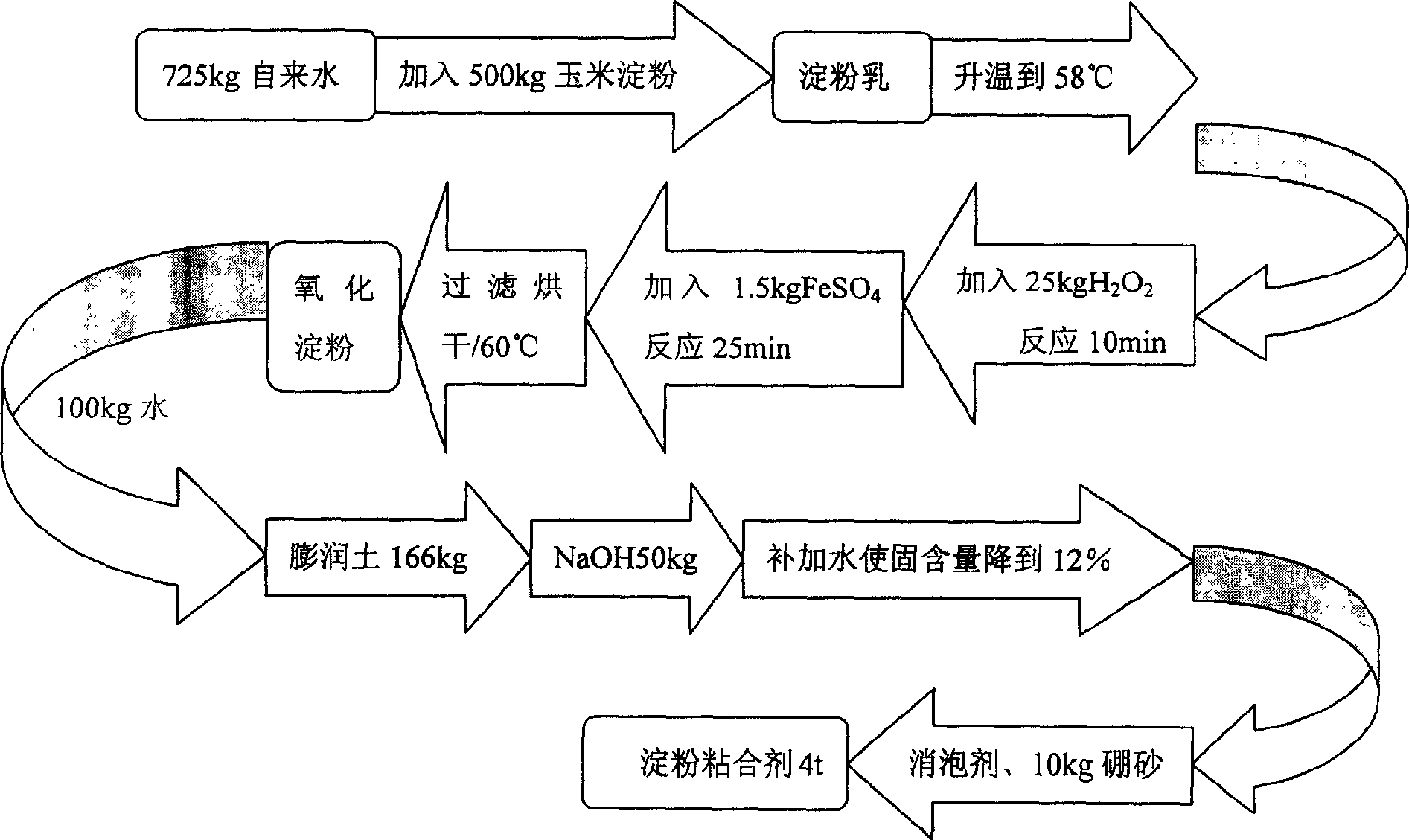

[0031] The present embodiment adopts the method of the present invention to prepare adhesive, taking 500kg corn starch as an example, the production process is as follows figure 2 shown.

[0032] Add 725kg of tap water to the reactor, start stirring, then add 500kg of cornstarch, heat up to 58°C, add 25kg of 27.5% concentration of commercially available hydrogen peroxide H 2 o 2 , keep the reaction for 10min, add 1.5kg FeSO 4 , and continue to react for 25 minutes (at this time, due to the intense heat release of the oxidation reaction in the reactor, attention should be paid to passing cold water to cool down, otherwise the temperature is too high, which may cause starch gelatinization), stop stirring, and discharge.

[0033] Put the starch milk in a centrifuge to shake off most of the water, dry it, and control the temperature of the hot air not higher than 60°C to obtain dry oxidized starch powder.

[0034] Take 50kg of oxidized starch, add 100kg of tap water into it, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com