Water-based drilling fluid with high suppression and lubrication performance and preparation method thereof

A water-based drilling fluid and drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high biological toxicity, application restrictions, poor compatibility, etc., achieve low solid content, reduce drill mud Packing and lubricating performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

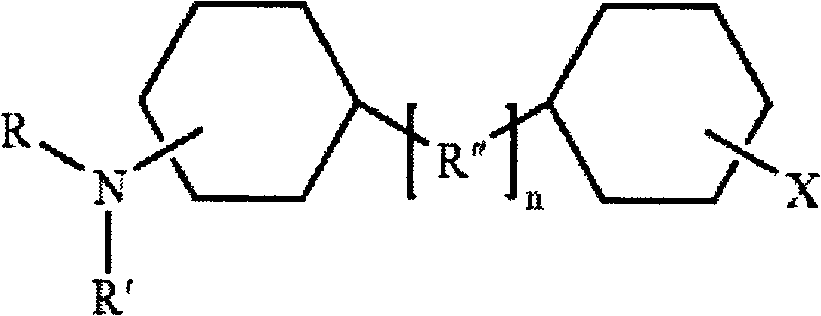

Method used

Image

Examples

Embodiment 1

[0034] To prepare water-based drilling fluid without heavy suppression and high lubrication: add 400mL seawater to the high-speed mixing cup, turn on the mixer, add 20g sodium chloride, 1.2g polyacrylamide (PAM), and 12g amines while stirring at 3000r / min Strong inhibitor (PCHA), 1.2g xanthan gum (XC), 4g low viscosity polyanionic cellulose (PAC-L), 8g water-based lubricant (SD-506) and 12g ultrafine calcium carbonate. Each treatment agent was added at intervals of 10 minutes, and stirred for 30 minutes after all were added.

[0035] The above-mentioned strong amine inhibitor (PCHA) is a product obtained by mixing cycloalkylamine and hydrochloric acid according to a molar ratio of 1:1.

Embodiment 2

[0037] The preparation density is 1.3g / cm 3 For strong suppression and high lubricating water-based drilling fluid, add 400mL of fresh water into the high-speed mixing cup, turn on the mixer, add 40g of potassium chloride, 1.2g of cationic polyacrylamide (CPAM), and 12g of amines for strong suppression while stirring at 3000r / min Agent (PMCHA), 1.2g xanthan gum (XC), 4g low viscosity carboxymethyl cellulose (CMC-L), 8g extreme pressure lubricant (SD-505), 12g ultrafine calcium carbonate and 170g barite. Each treatment agent was added at intervals of 10 minutes, and stirred for 30 minutes after all were added.

[0038] The aforementioned strong inhibitor of amines (PMCHA) is a product obtained by mixing N-methylcyclohexylamine and formic acid in a molar ratio of 1:1.

Embodiment 3

[0040] Preparation of non-intensive strong suppression, high-lubrication water-based drilling fluid: add 400mL seawater into the high-speed mixing cup, turn on the mixer, add 9g sodium chloride and 20g potassium chloride, 1.2g zwitterionic polymer while stirring at 3000r / min FA367), 1.2g strong amine inhibitor (PDMCHA), 1.2g xanthan gum (XC), 4g hydroxyethyl cellulose (HEC), 8g nanoemulsion, 12g ultrafine calcium carbonate. Each treatment agent was added at intervals of 10 minutes, and stirred for 30 minutes after all were added.

[0041] The aforementioned strong inhibitor of amines (PDMCHA) is a product obtained by mixing N,N-dimethylcyclohexylamine and citric acid according to a molar ratio of 1:1.

[0042] Effects in the examples will be described below.

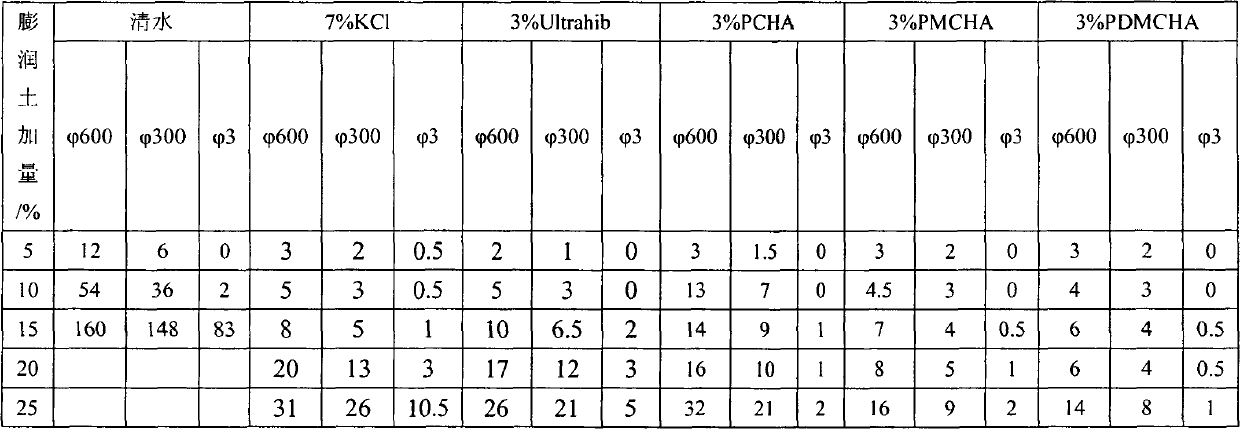

[0043] First, in order to evaluate the inhibitory performance of the strong amine inhibitors as shale inhibitors, the performance of the strong amine inhibitors was compared with the traditional inorganic salt inhibitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com