Polycrystalline diamond compact sheet and PDC bit

A technology of polycrystalline diamond and composite sheet, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc. It can solve the problems affecting the application effect of PDC bit, the instability of directional deflection tool face, and the restriction of the application of PDC bit, so as to reduce the number of drill bits. The effects of mud bag, good mechanical footage, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

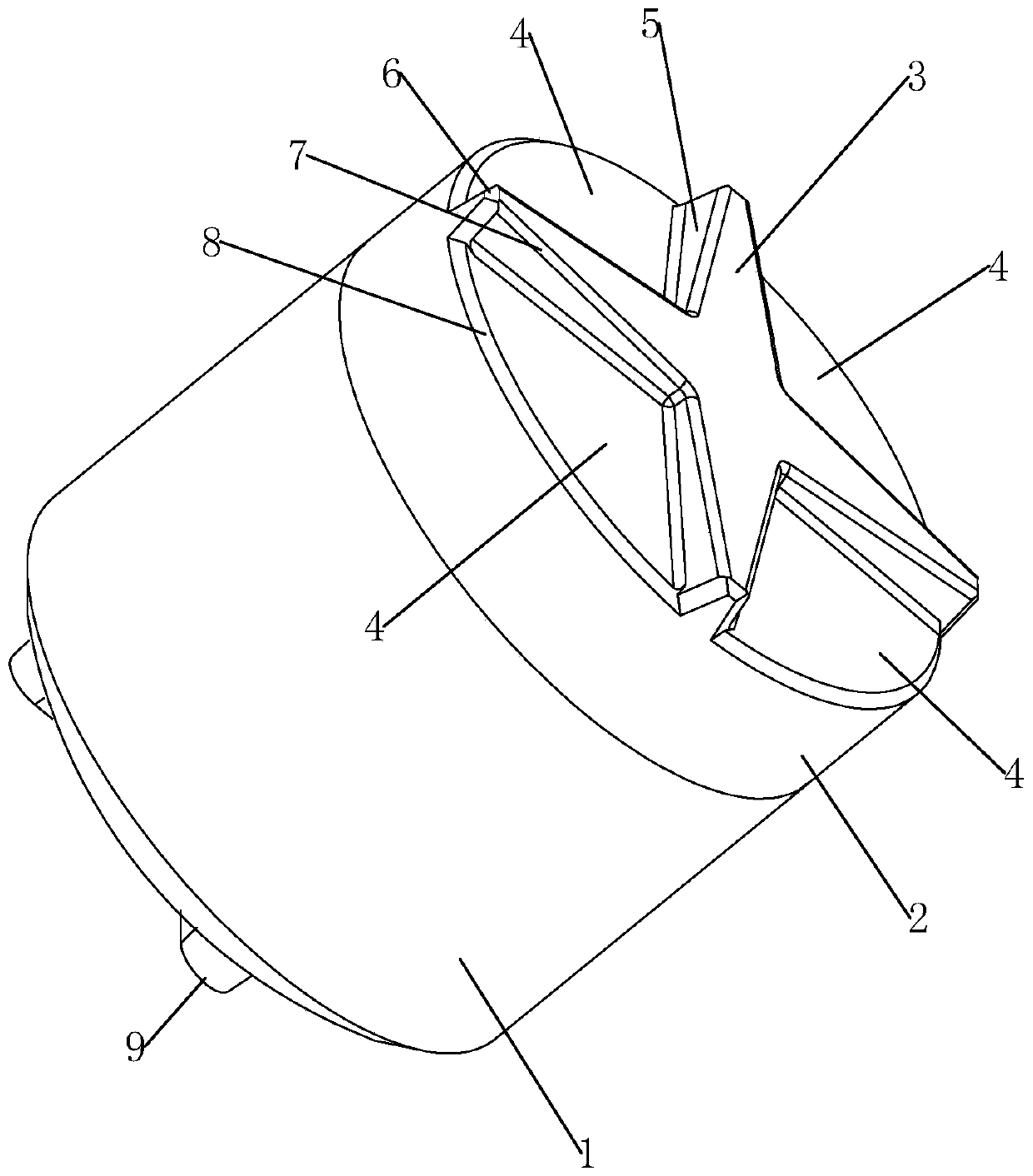

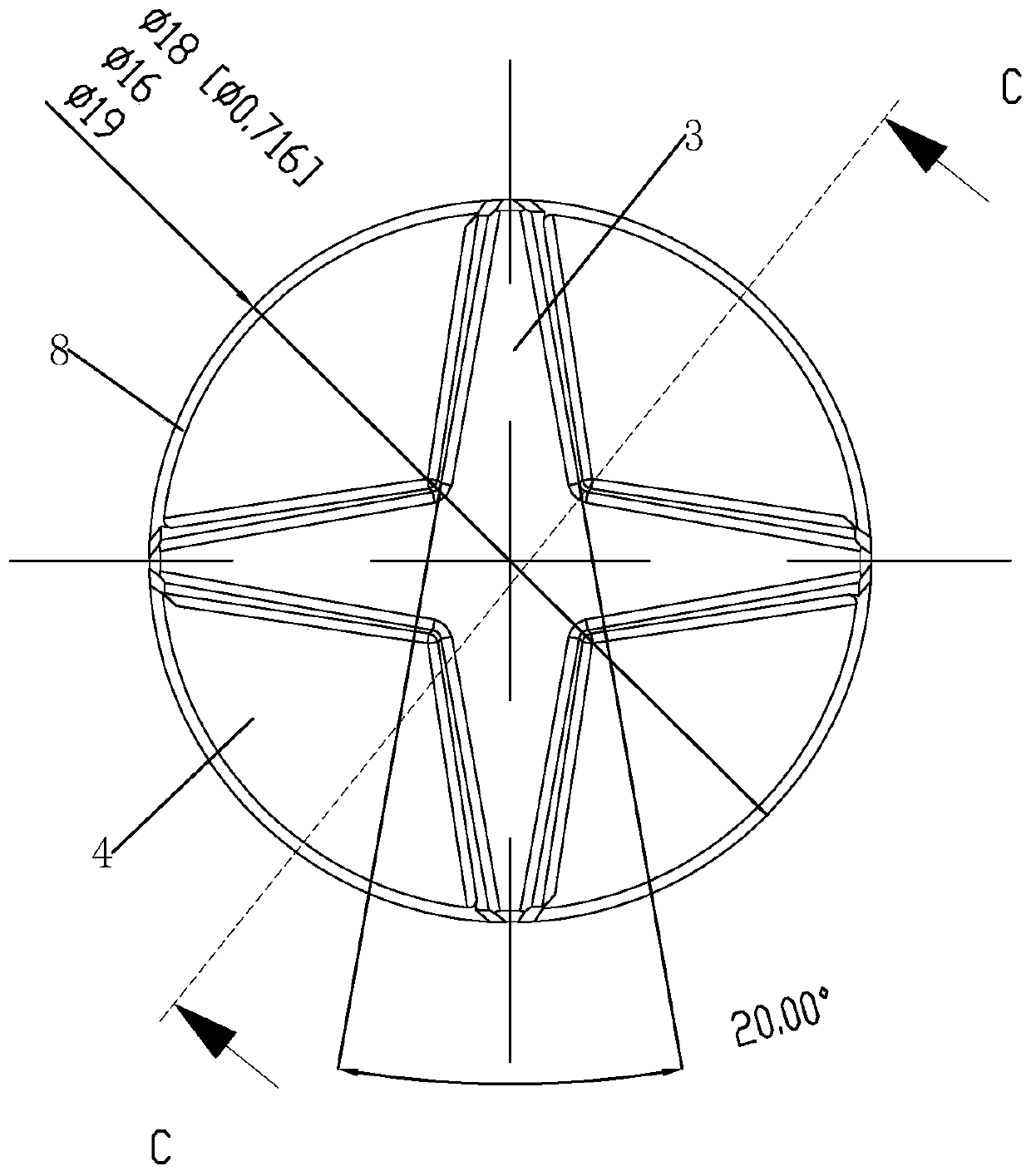

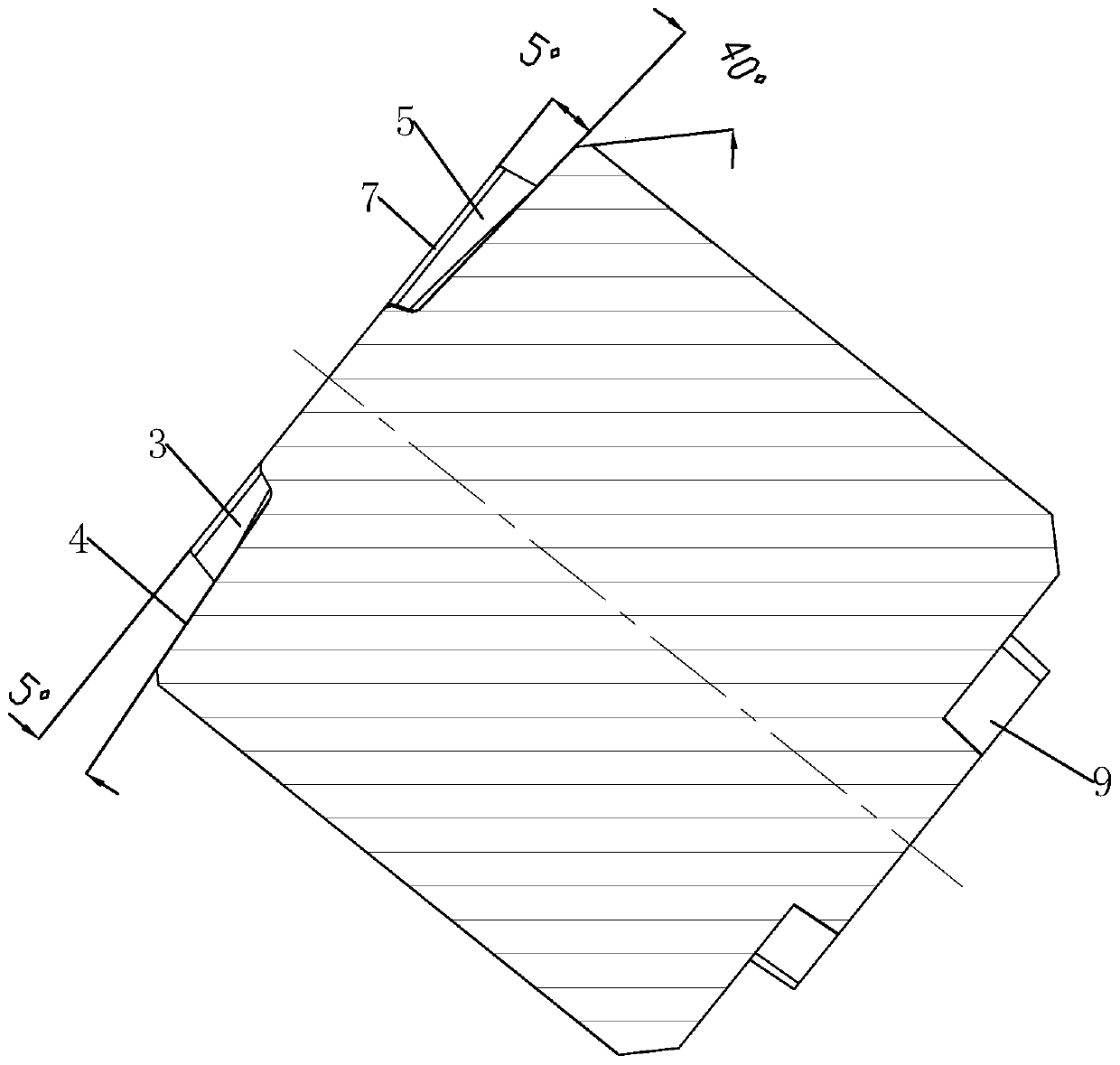

[0027] As one aspect of the present invention, a polycrystalline diamond compact is provided, especially a PDC drill bit diamond tooth used in oil and gas development drilling, including: a cemented carbide base 1 and a diamond layer 2, one of the diamond layers 2 The side is connected with the first side of the cemented carbide base 1 , and the surface of the diamond layer 2 away from the cemented carbide base 1 is protrudingly formed with a cross-shaped star-shaped cutting protrusion 3 .

[0028] Wherein, the width of each of the cutting protrusions 3 gradually decreases from the center of the diamond layer 2 to the outer edge, and a radial plane relative to the diamond layer 2 is formed between two adjacent cutting protrusions 3 The inclined cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com