Flux

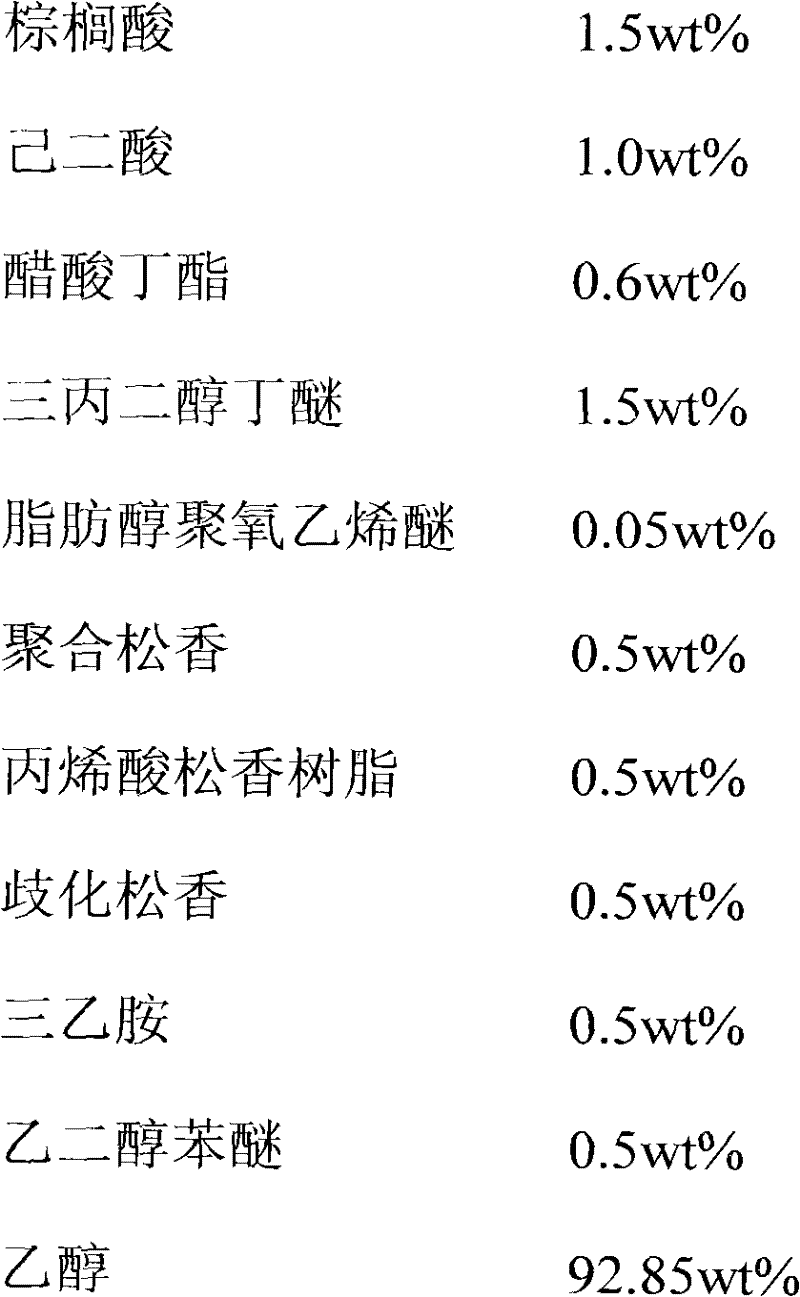

A technology of flux and activator, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of residual dirt on the surface of the circuit board, prone to leakage risk, low insulation resistance, etc., and achieve low solid content. , The effect of high insulation resistance and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

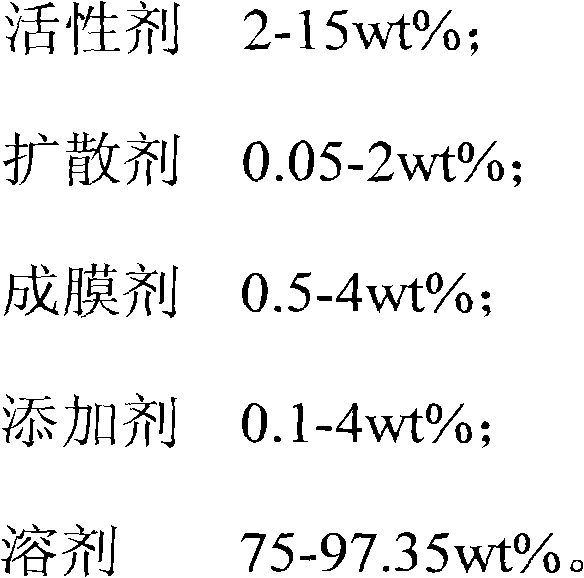

[0016] The components of the flux and the weight percent content of each component are:

[0017]

[0018] The flux is made as follows:

[0019] The solvent (isopropanol) is first added to the stirred tank, and then the active agent (succinic acid, itaconic acid, glycolic acid and dipropylene glycol methyl ether), film forming agent (hydrogenated rosin), additive (benzotriazepam, etc.) azole, stearic acid and dimethylacetamide) into the stirring tank, stirring at room temperature, when stirring until the material is completely dissolved, add a diffusing agent (non-ionic fluorosurfactant), stir and mix evenly, stop After stirring and filtering, the product is obtained, and the soldering flux of the present invention is obtained.

Embodiment 2

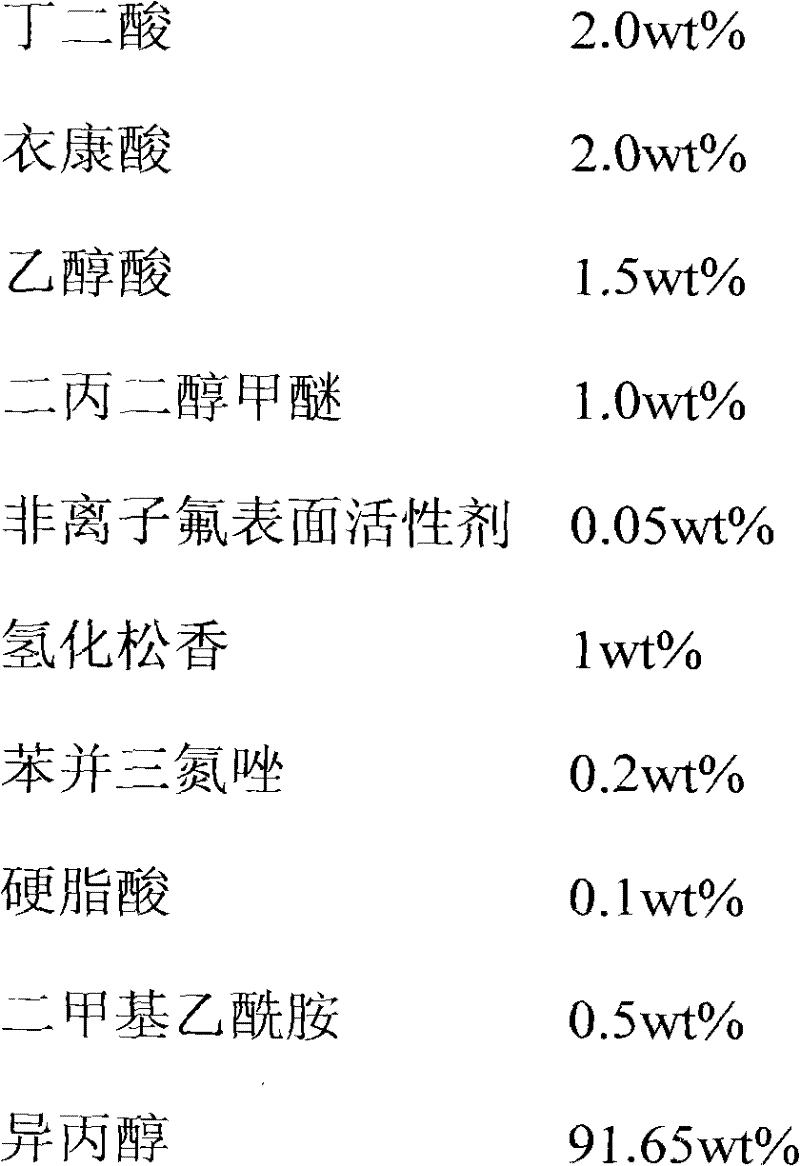

[0021] The components and weight percentages of the flux are:

[0022]

[0023] The flux is made as follows:

[0024] First add the solvent (ethanol) into the stirring tank, then the active agent (palmitic acid, adipic acid, butyl acetate and tripropylene glycol butyl ether), film-forming agent (polymerized rosin, acrylic rosin resin and disproportionated rosin), additives (triethylamine and ethylene glycol phenyl ether) into the stirring tank, stirring at room temperature, when stirring until the material is completely dissolved, add a diffusing agent (fatty alcohol polyoxyethylene ether), stir and mix evenly, stop stirring , which is the product after filtering to obtain the soldering flux of the present invention.

Embodiment 3

[0026] The composition and weight percentage of flux are:

[0027]

[0028] The flux is made as follows:

[0029] First add the solvent (propanol and isopropanol) into the stirred tank, then add the active agent (malonic acid, ethyl acetate, diethanolamine and ethylene glycol phenyl ether), film forming agent (water white rosin, acrylic resin, polyacrylamide and sorbitol), additives (dimethylacetamide, ethylene glycol monobutyl ether and lauramide) into the stirring tank, stirring at room temperature, when stirring until the material is completely dissolved, add the diffusing agent (perfluoroalkylammonium), after stirring and mixing evenly, stop stirring, and obtain the product after filtering to obtain the soldering flux of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com