Device for preparing biofuel by quick thermal cracking of biomass

A biofuel and thermal cracking technology, applied in the preparation of biofuels, liquid hydrocarbon mixtures, educts, etc., can solve the problems of easy bridging of materials, high content of solid particles, uneven feeding, etc., to improve yield, reduce The effect of separating cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following implementation. example.

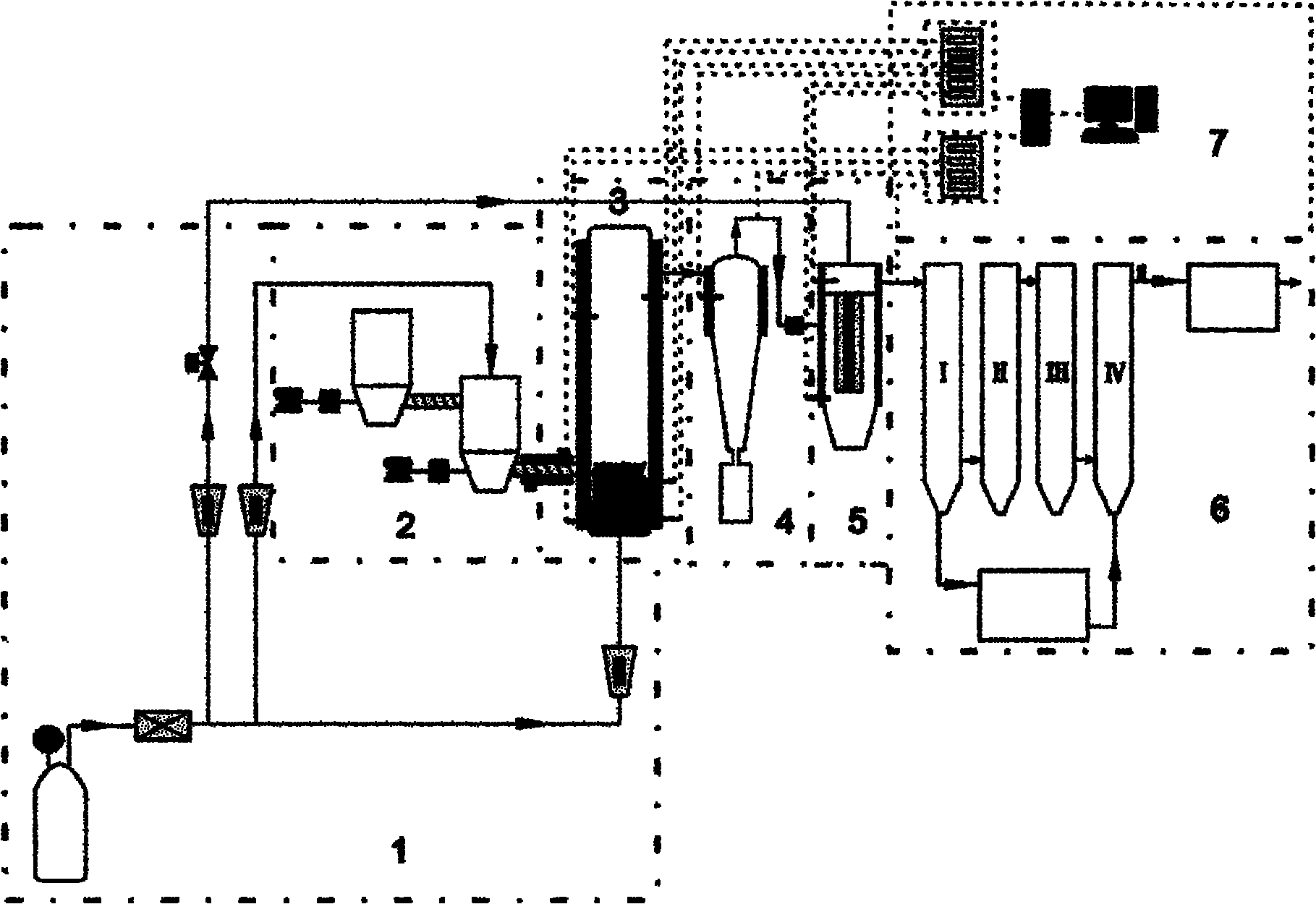

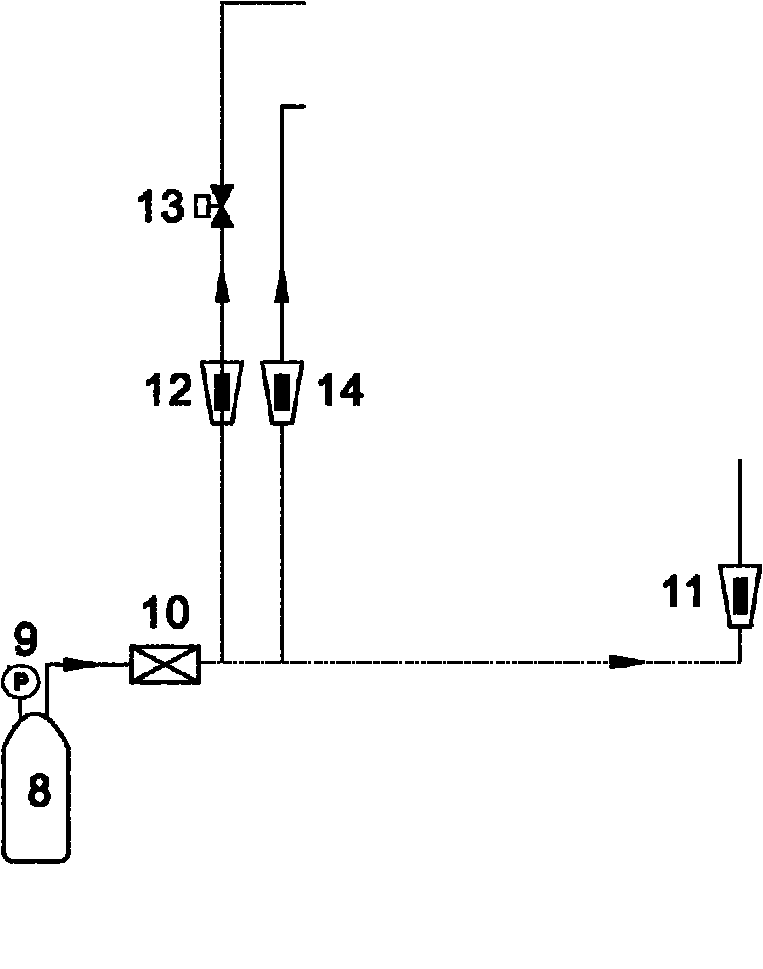

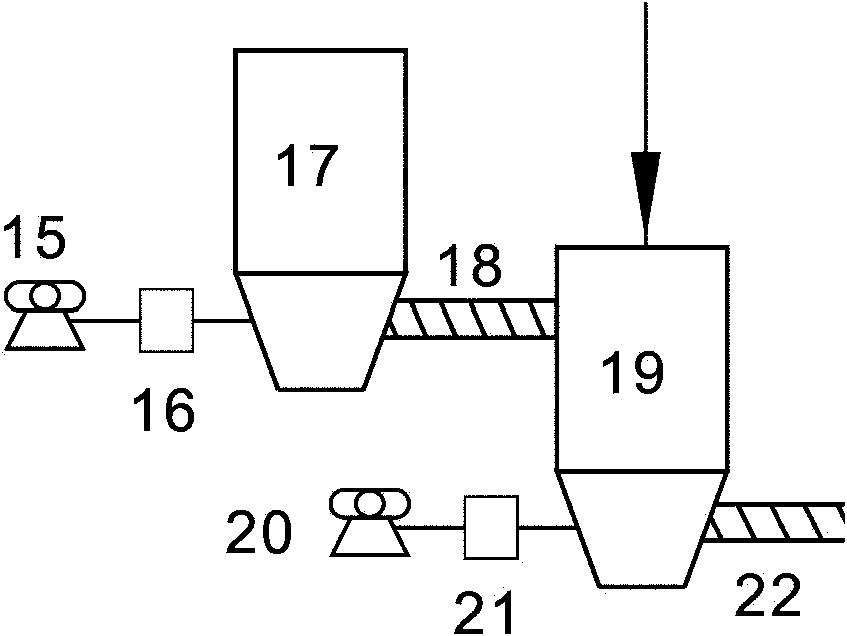

[0024] like figure 1 As shown, the present invention includes: a carrier gas system 1, a feeding system 2, a fluidized bed reactor 3, a cyclone separator 4, a hot vapor filter 5, a biofuel collection system 6, a sensing mechanism and a data acquisition control system 7 , wherein: the carrier gas system 1 is connected to the bottom of the fluidized bed reactor 3 through a gas conduit, the feed system 2 is connected to the bottom of the fluidized bed reactor 3 through a twin screw perpendicular to the wall of the fluidized bed reactor 3, the fluidized bed reactor 3, cyclone separation The sensor 4, the hot steam filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com