Flour/bean product extrusion mechanism

A soy product and screw technology, applied in the field of food processing machinery, can solve the problems of uneven product aging, poor feeding, poor taste, etc., and achieve the effects of stable transmission, uniform force and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below.

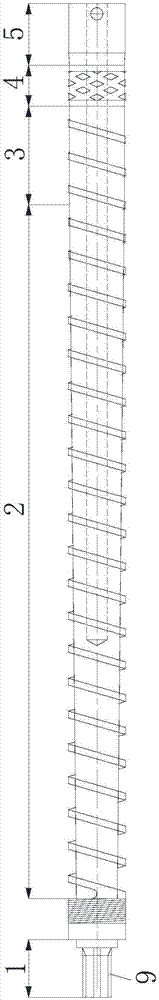

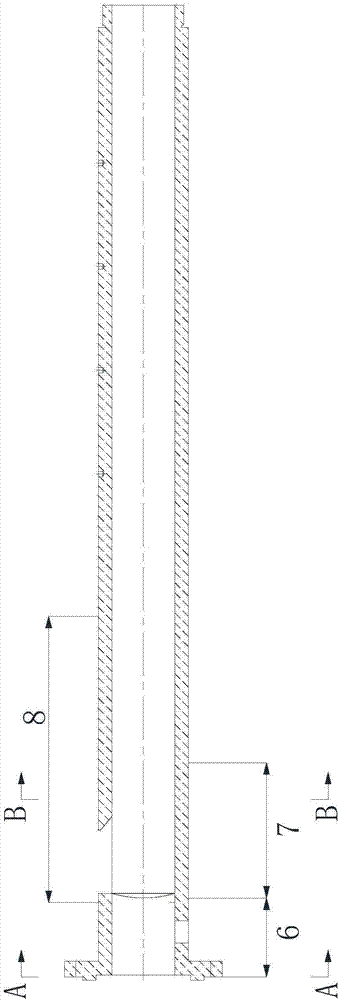

[0031] The extruding mechanism for noodles or soybean products includes a screw and a barrel, and the barrel is set outside the screw. The front end of the screw is connected to the power mechanism of the extruder through the spline, and the power mechanism drives the screw to rotate through the spline.

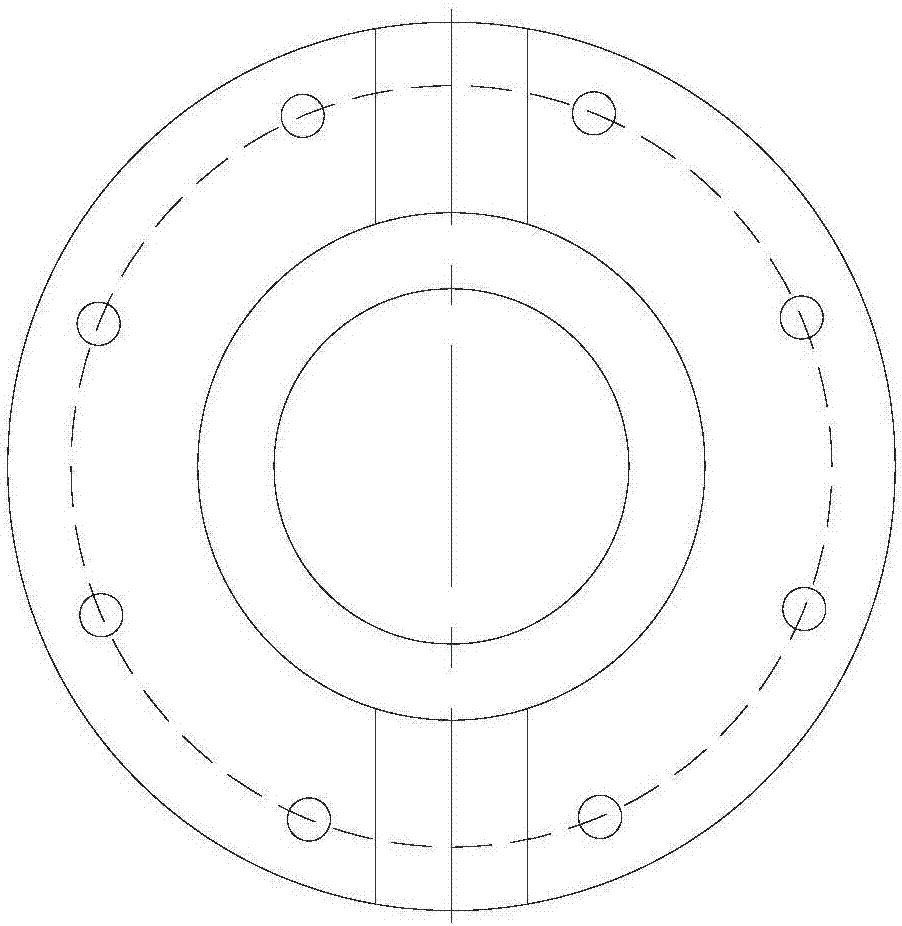

[0032] The screw includes the screw drive joint, the feeding section, the first aging section for the first compression of the material, the second aging section for the second compression of the material, and the second aging section for the second compression of the material. The material mixed for the third time is mixed in the third ripening section, and the material extrusion buffer section is used to release the pressure and expand the material. The connecting head of the screw drive is provided with a hexagonal fancy keyway and a cylindrical straight screw positioning device; the screw and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com