Air-exchanging structure of crank case of four-stroke engine

A four-stroke engine and crankcase technology, applied in engine components, crankcase ventilation, machine/engine, etc., can solve the problems of complex structure, difficult to achieve lightweight, etc., to ensure lightweight, good space efficiency, good oil return effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

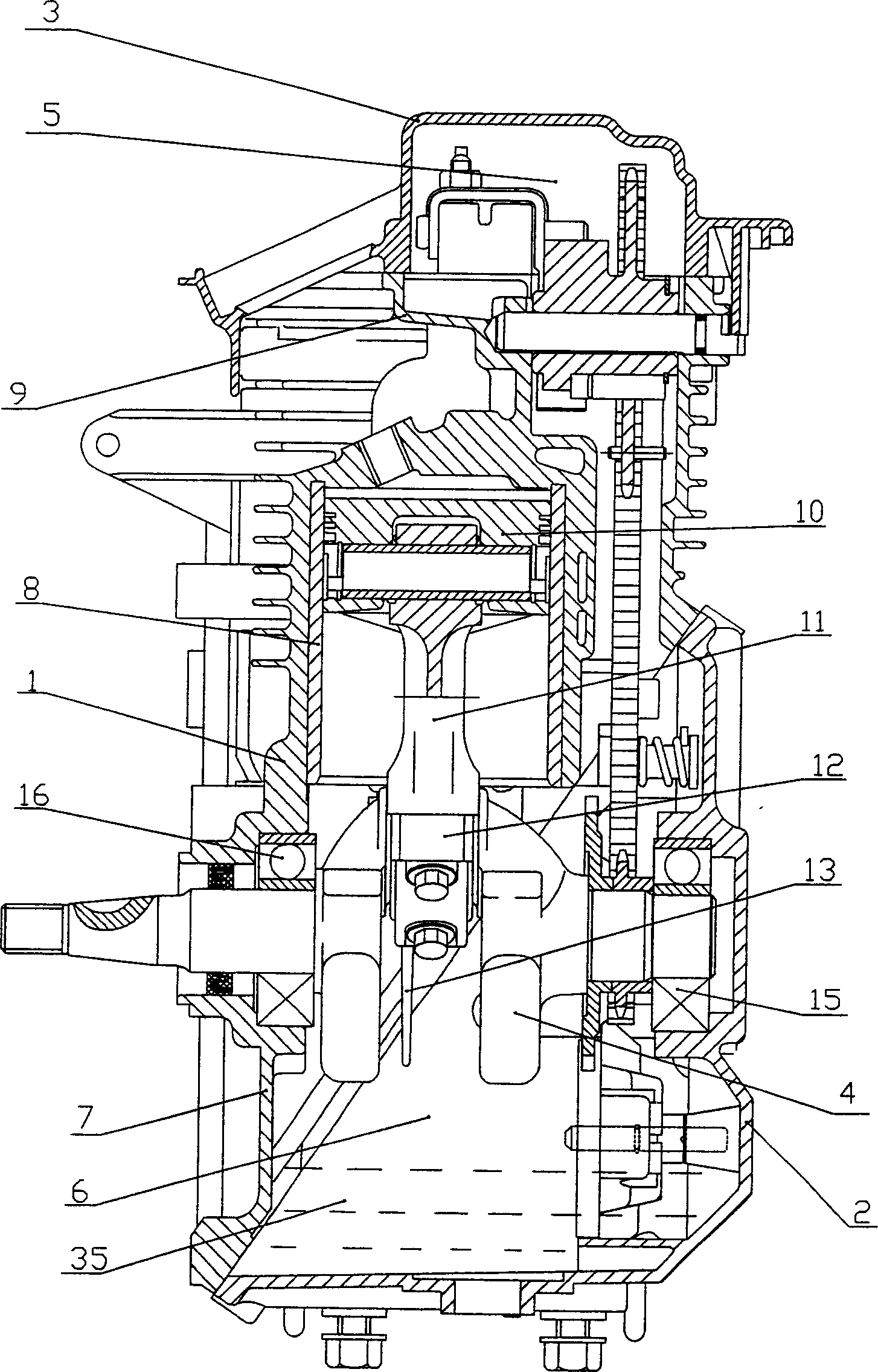

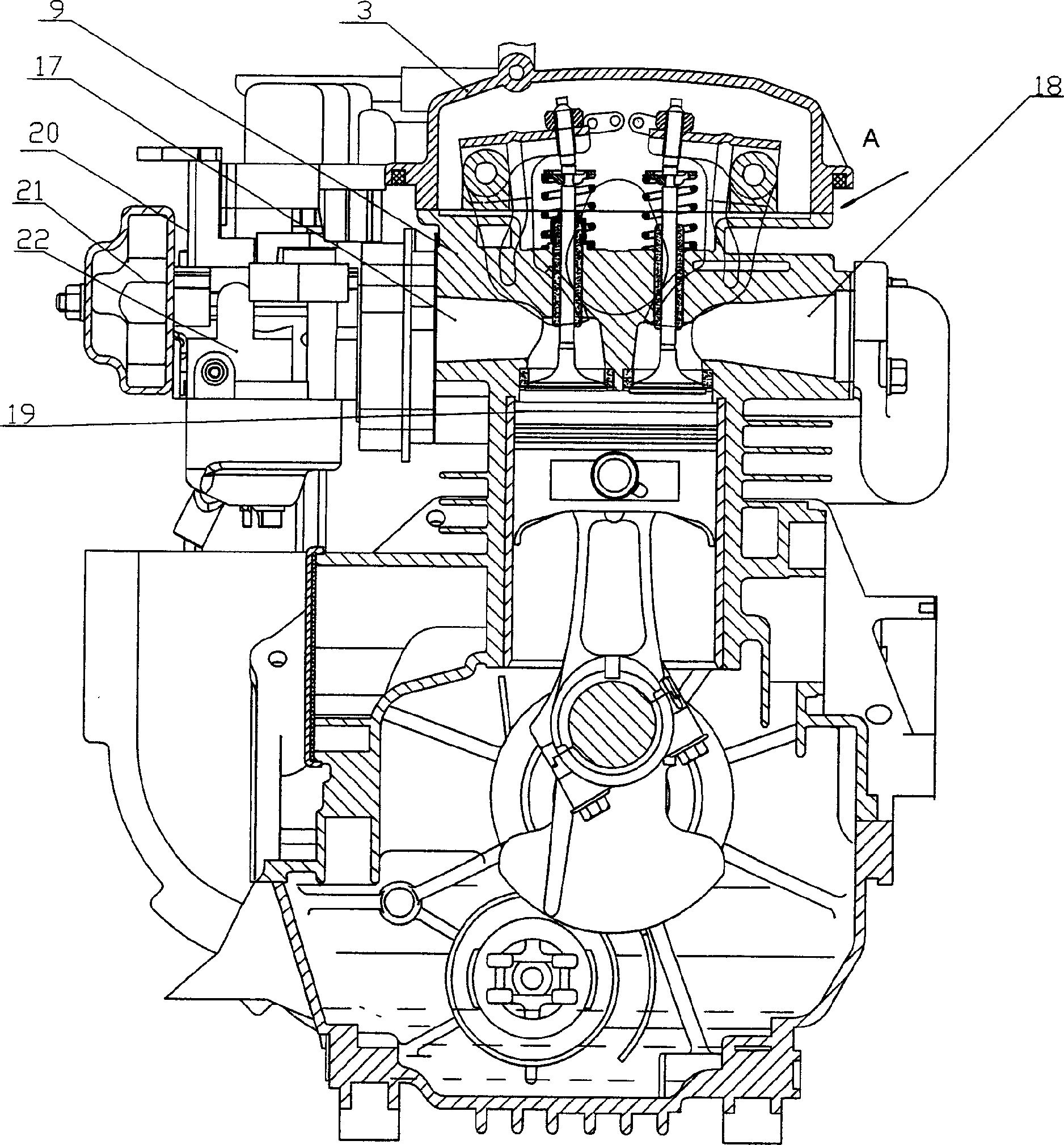

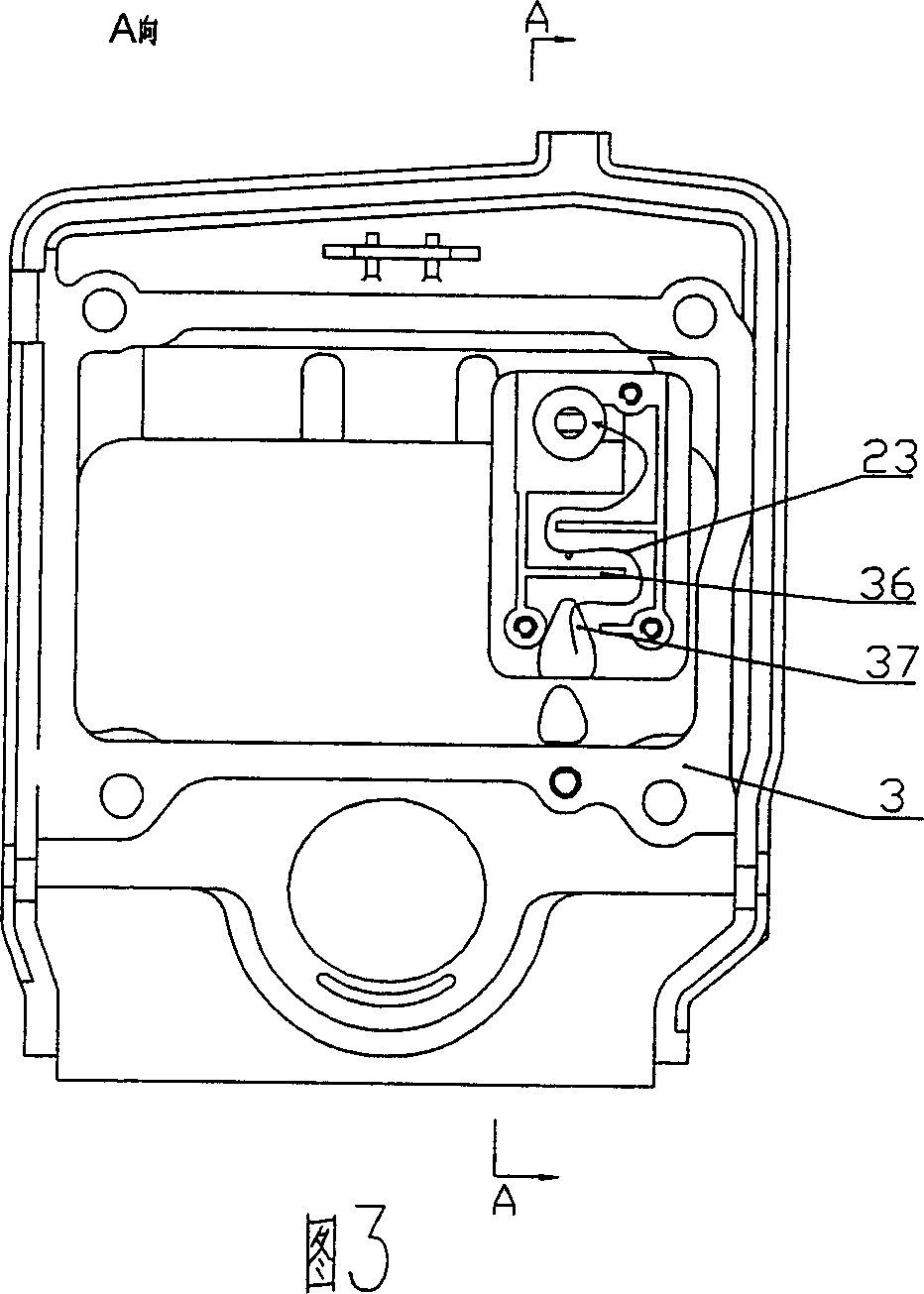

[0014] The present invention mainly consists of engine body 1, crankcase cover 2, cylinder head cover 3, crankshaft 4, valve control chamber 5, crankcase 6, engine casing 7, cylinder liner 8, cylinder head 9, piston 10, connecting rod 11 , connecting rod cover 12, oil needle 13, ball bearings 15, 16, air inlet 17, exhaust port 18, combustion chamber 19, suction system 20, air filter 21, carburetor 22, oil and gas Separation chamber 23, screw 24, partition 25, oil-gas separation chamber 26, one-way valve 27, one-way valve hole 28, valve seat 29, plastic ball 30, cylindrical pin 31, sealing ring 32, cylinder head cover channel 33, return Oil hole 34, lubricating oil 35, labyrinth forming wall 36, channel 37, inclined hole 38, plug 39, hollow positioning pin 40, cylinder head communication passage 41, intake pipe 14 etc. are formed.

[0015] The present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com