Patents

Literature

62results about How to "Improve oil return efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-returning control method and oil-returning device for compressor as well as air conditioner

ActiveCN105299979AGuaranteed normal oil returnReduce normal oil returnMechanical apparatusFluid circulation arrangementEngineeringMechanical engineering

The invention discloses an oil-returning control method and an oil-returning device for a compressor as well as an air conditioner. The air conditioner comprises the compressor, an oil separator, an oil-returning pipeline and a controller, wherein an inlet of the oil separator is connected with an exhaust port of the compressor and receives gas-oil mixtures exhausted by the compressor for separation; the oil-returning pipeline is connected between an oil outlet of the oil separator and the compressor and returns oil separated by the oil separator to the compressor; a plurality of throttling pipelines are arranged in the oil-returning pipeline and in parallel connection; and the controller is used for regulating the working frequencies of the compressor and carrying on gate control on the throttling pipelines according to the working frequencies of the compressor. According to the oil-returning control method and the oil-returning device for the compressor as well as the air conditioner, a plurality of throttling pipelines are arranged in parallel in the oil-returning pipeline of the compressor, and gate control on each oil-returning pipeline is carried on according to different working frequencies of the compressor, so that the compressor can be guaranteed to return oil normally in various working conditions, and the oil-returning amount is guaranteed.

Owner:青岛海信网络能源股份有限公司

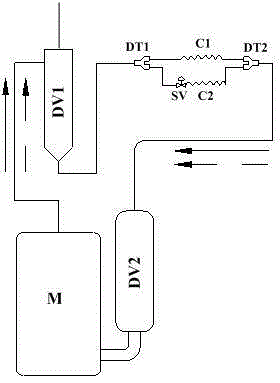

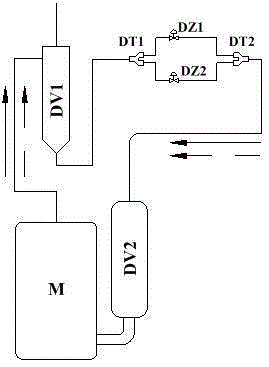

Transcritical carbon dioxide heat pump device

PendingCN106918160AEasy to useImprove oil return efficiencyHeat pumpsCompression machinesVapor–liquid separatorSolenoid valve

The invention discloses a transcritical carbon dioxide heat pump device, comprising a compressor, a high-pressure oil separator, a gas cooler, a heat regenerator, a throttling gear, an air cooling evaporator, and a gas-liquid separator connected in a carbon dioxide circulation pipeline in sequence according to a flow direction of carbon dioxide. A hand valve A, a filter A, and a solenoid valve A are connected between the heat regenerator and the throttling gear in sequence through a pipeline. A hand valve B and a filter B are connected between the gas-liquid separator and the compressor in sequence through a pipeline. The device is characterized in that a carbon dioxide outlet pipeline position in the gas-liquid separator is provided with an oil return hole. A solenoid valve B, a capillary tube, a filter C, a hand valve C, an oil storage tank, and an oil level controller are connected between the an oil outlet of the high-pressure oil separator 2 and an oil inlet of the compressor in sequence through a pipeline. The product has functions of low pressure liquid storage, defrosting, and backheating, and operation of a unit in low temperature environment is safer, more reliable, and more efficient.

Owner:ZHENGZHOU YUNYU NEW ENERGY TECH CO LTD

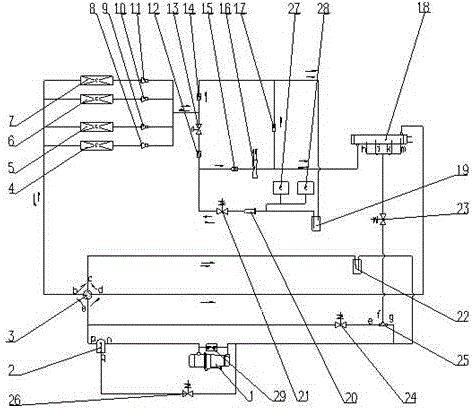

Flooded evaporator oil return system and water-cooled air conditioning unit adopting flooded evaporator oil return system

PendingCN106440538AImprove oil return efficiencyIncrease profitCompressorEvaporators/condensersLiquid stateFuel tank

The invention relates to the technical field of air conditioning equipment, in particular to a flooded evaporator oil return system and a water-cooled air conditioning unit adopting the flooded evaporator oil return system. The flooded evaporator oil return system comprises an oil and refrigerant mixed liquid recovery pipeline, a separated oil recovery pipeline and an oil and refrigerant separator; an inlet end of the oil and refrigerant mixed liquid recovery pipeline communicates with an oil return port of a flooded evaporator, an outlet end of the oil and refrigerant mixed liquid recovery pipeline communicates with the oil and refrigerant separator, and oil and refrigerant mixed liquid in the flooded evaporator is drained to the oil and refrigerant separator; the oil and refrigerant separator is arranged in the flooded evaporator and carries out separation of oil and a refrigerant by employing heat of chilled water; and the separated oil recovery pipeline communicates with the bottom of the oil and refrigerant separator, and drains separated oil to an oil tank or an air inlet of a compressor. With the adoption of the oil return mode, the oil return efficiency of the flooded evaporator is improved, a utilization ratio of the liquid-state refrigerant of the flooded evaporator is increased, and long-time oil return can be realized due to the fact that the oil and refrigerant mixed liquid dose not enter the compressor or the oil tank.

Owner:GREE ELECTRIC APPLIANCES INC

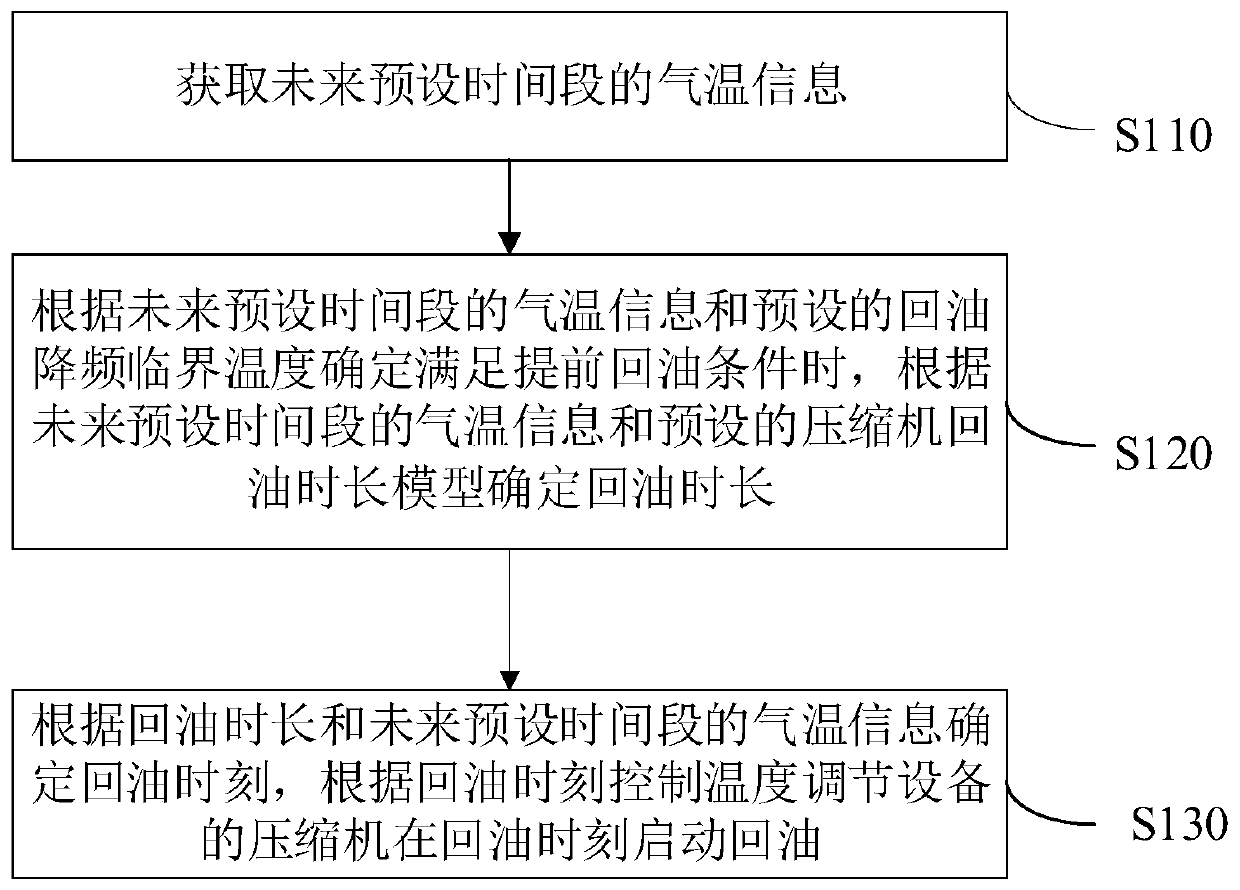

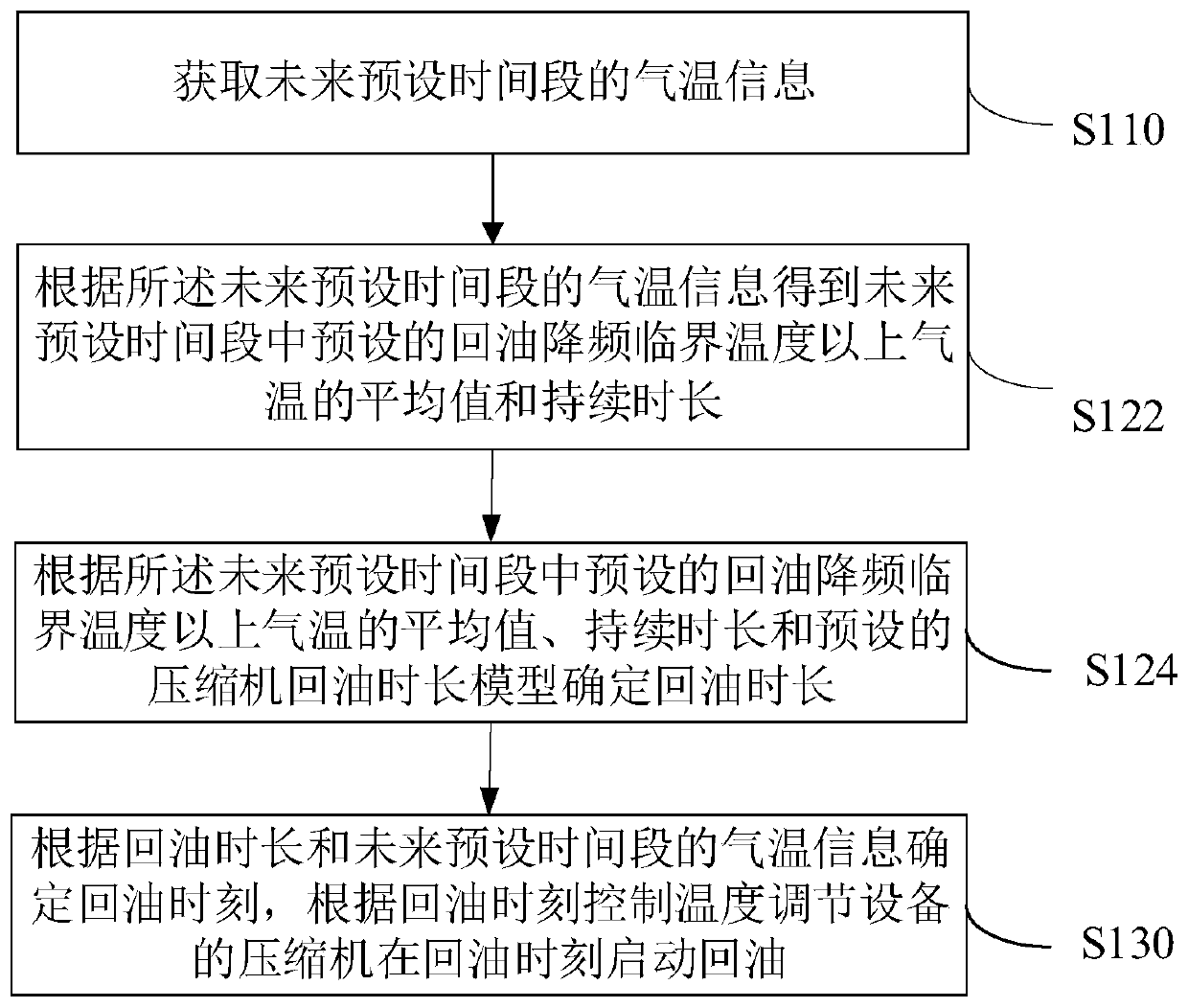

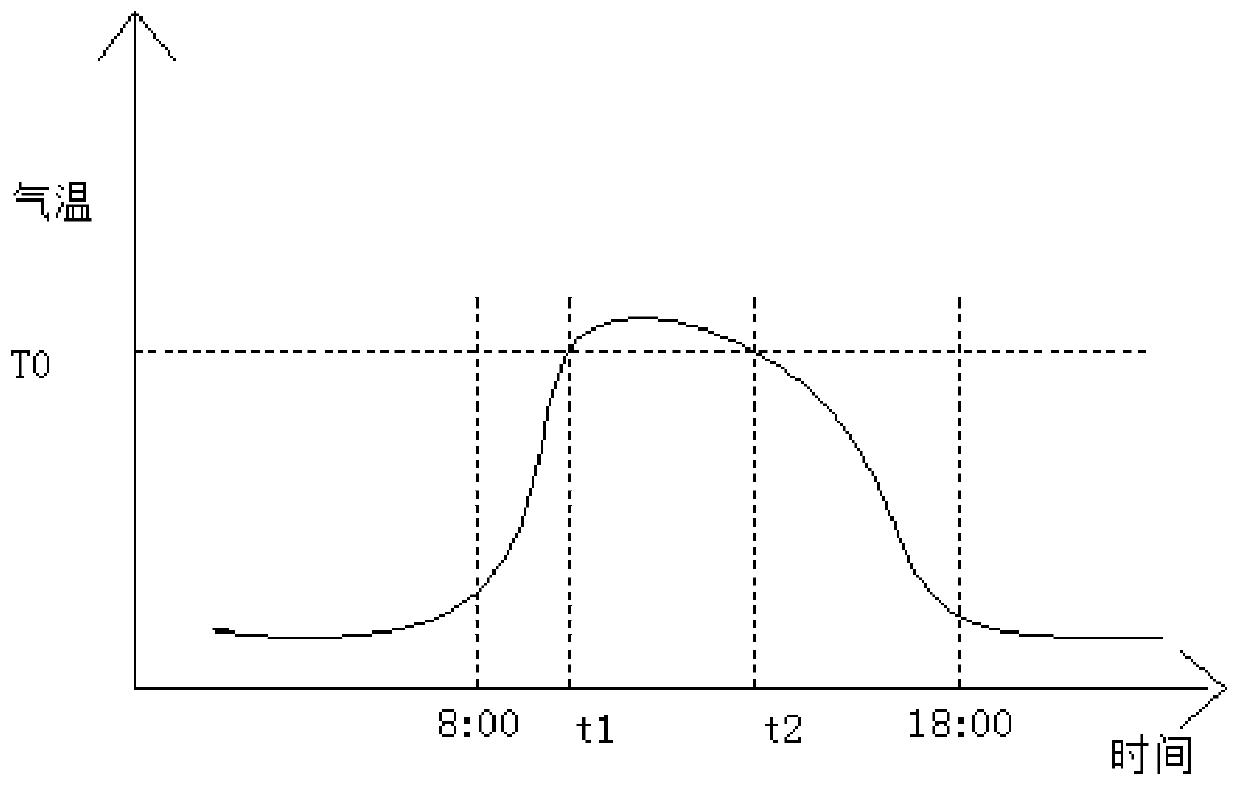

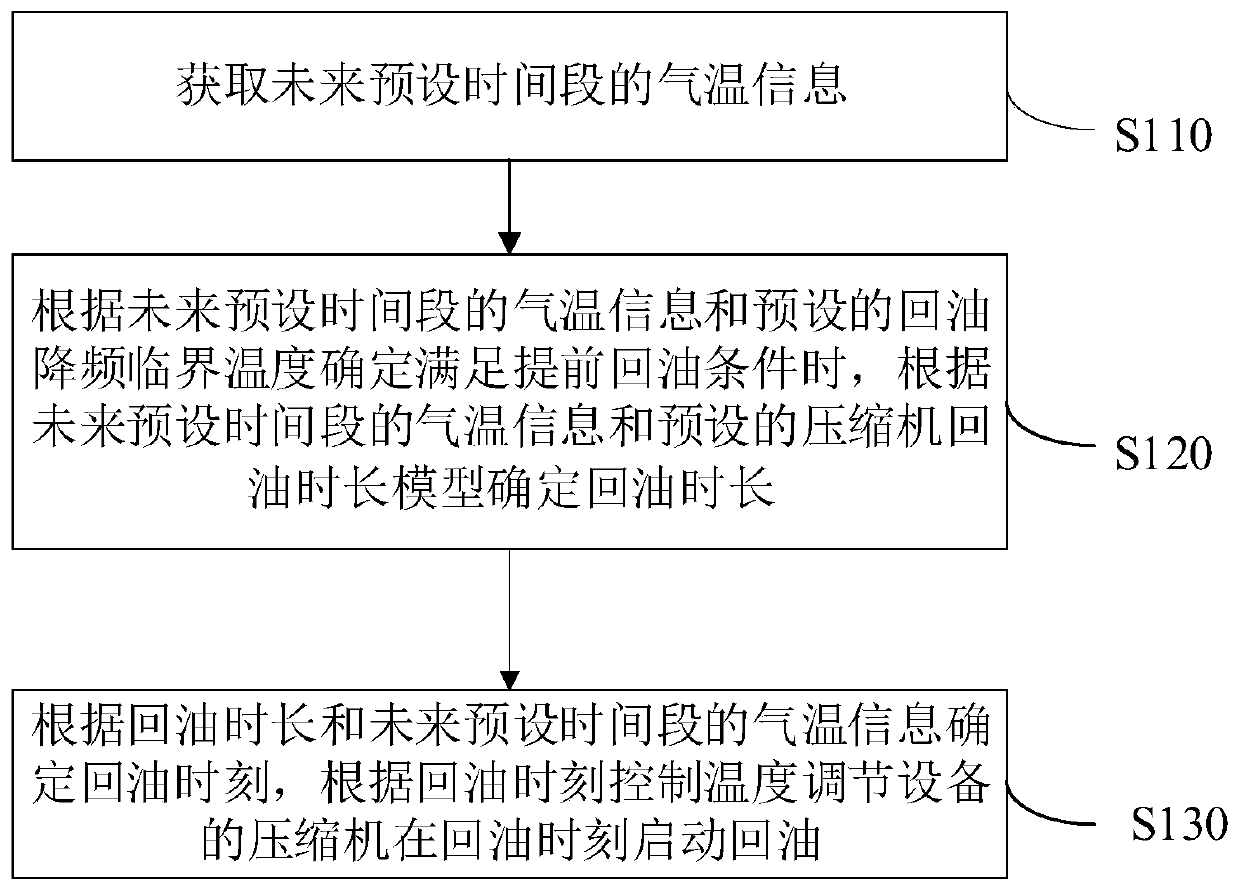

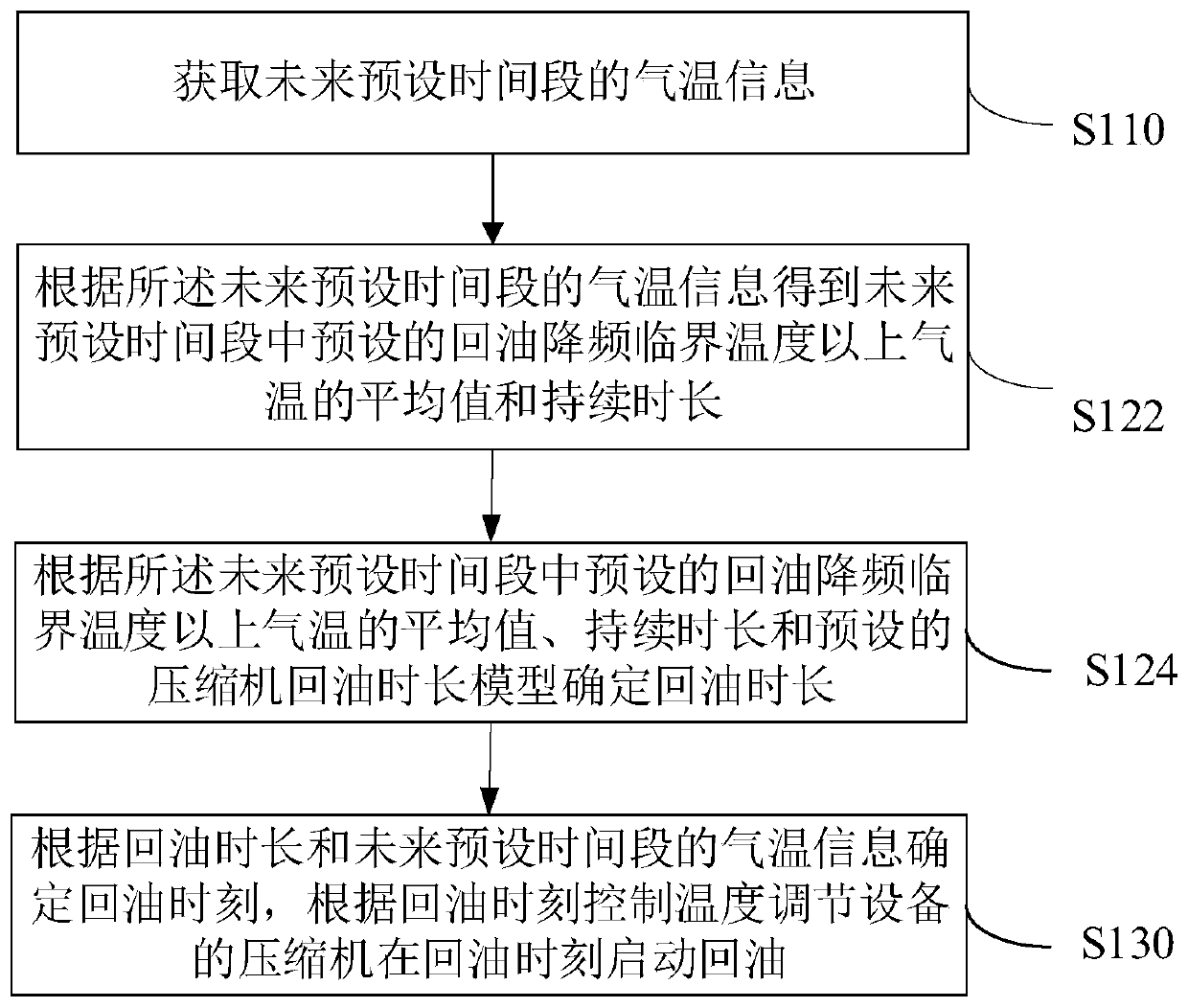

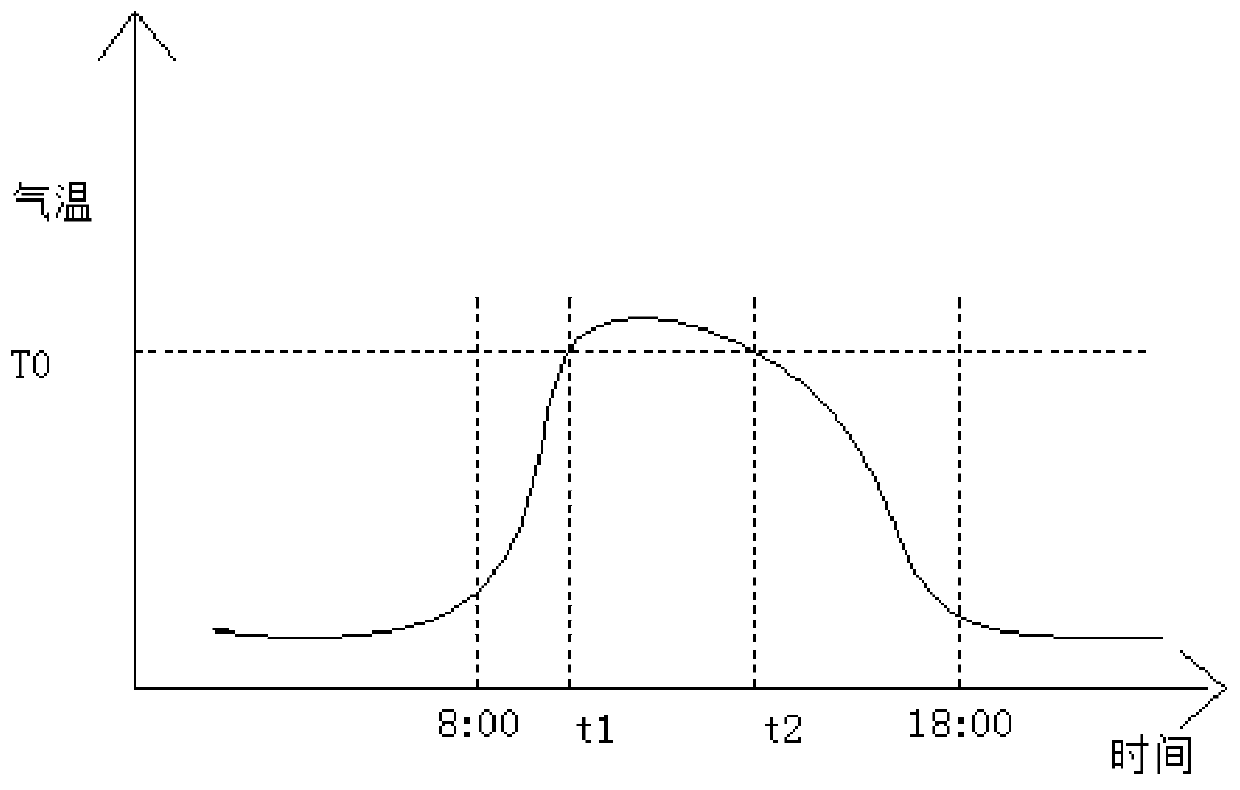

Temperature adjusting equipment oil return control method, device and system and air conditioner

ActiveCN110285544AThrottling does not occurImprove oil return efficiencyCompressorMechanical apparatusEngineeringFrequency reduction

The invention relates to a temperature adjusting equipment oil return control method, device and system and an air conditioner. Air temperature information within the future preset time period is obtained; when it is determined that the advance oil return condition is met according to the air temperature information within the future preset time period and the preset oil return frequency reduction critical temperature, the oil return duration is determined according to the air temperature information within the future preset time period and a preset compressor oil return duration model; and the oil return timing is determined according to the oil return duration and the air temperature information within the future preset time period, and according to the oil return timing, a compressor of temperature adjusting equipment is controlled to start oil return at the oil return timing. When it is judged that oil return needs to be conducted in advance by combining the air temperature information within the future preset time period with the preset oil return frequency reduction critical temperature, the advance oil return timing is determined according to the air temperature information within the future preset time period and the preset compressor oil return duration model, thus, the compressor completes oil return before the air temperature is raised to the preset oil return frequency reduction critical temperature, it is ensured that the compressor can conduct oil return at the highest frequency, and protective frequency reduction does not occur, and the oil return efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

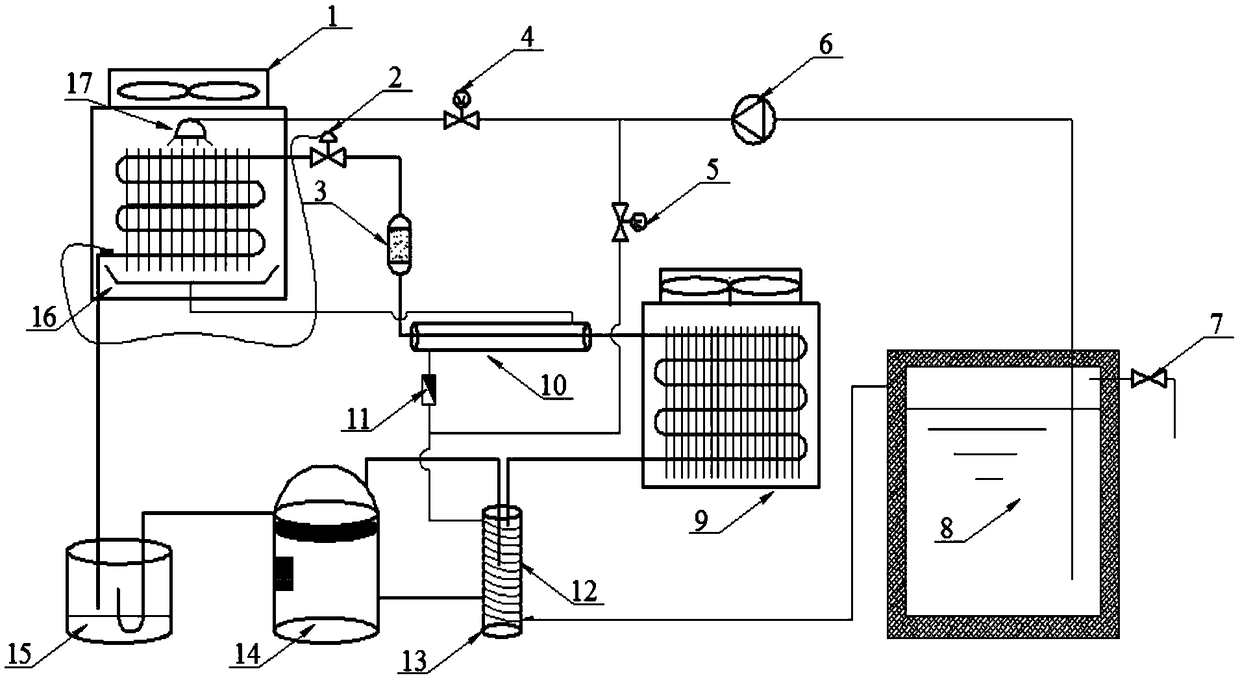

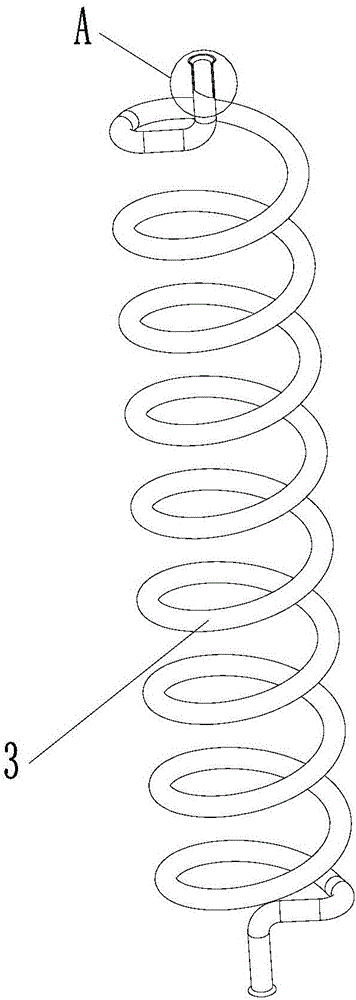

Energy and water saving type hot water spraying and defrosting system

InactiveCN108844265AIncrease subcoolingReduce energy consumptionCorrosion preventionRefrigeration componentsWater savingVapor–liquid separator

The invention discloses an energy and water saving type hot water spraying and defrosting system. The system consists of a refrigerating system, a defrosting system and a control system; the refrigerating system comprises a compressor, an oil separator, an air cooling condenser, a drying filter, a thermal expansion valve, a fin tube evaporator and an air-liquid separator; the defrosting system comprises a water storage tank, a water pump and a spraying device; a water outlet of the water storage tank is connected with a water feeding pipeline provided with the water pump and a first electromagnetic valve in sequence; the spraying device is mounted at the tail end of the water feeding pipeline; and a water collecting disc positioned at the bottom in the fine tube evaporator is connected with a sleeve heat exchanger, a one-way valve, a snakelike coil around the outer side of the oil separator and a water storage tank water inlet through pipelines in sequence. The system needs no additional defrosting heat source and defrosting water; and through efficient utilization of condensation heat and afterheat of the oil separator and recycling of the defrosting water, the energy and water saving purpose of the system can be achieved.

Owner:TIANJIN UNIV OF COMMERCE

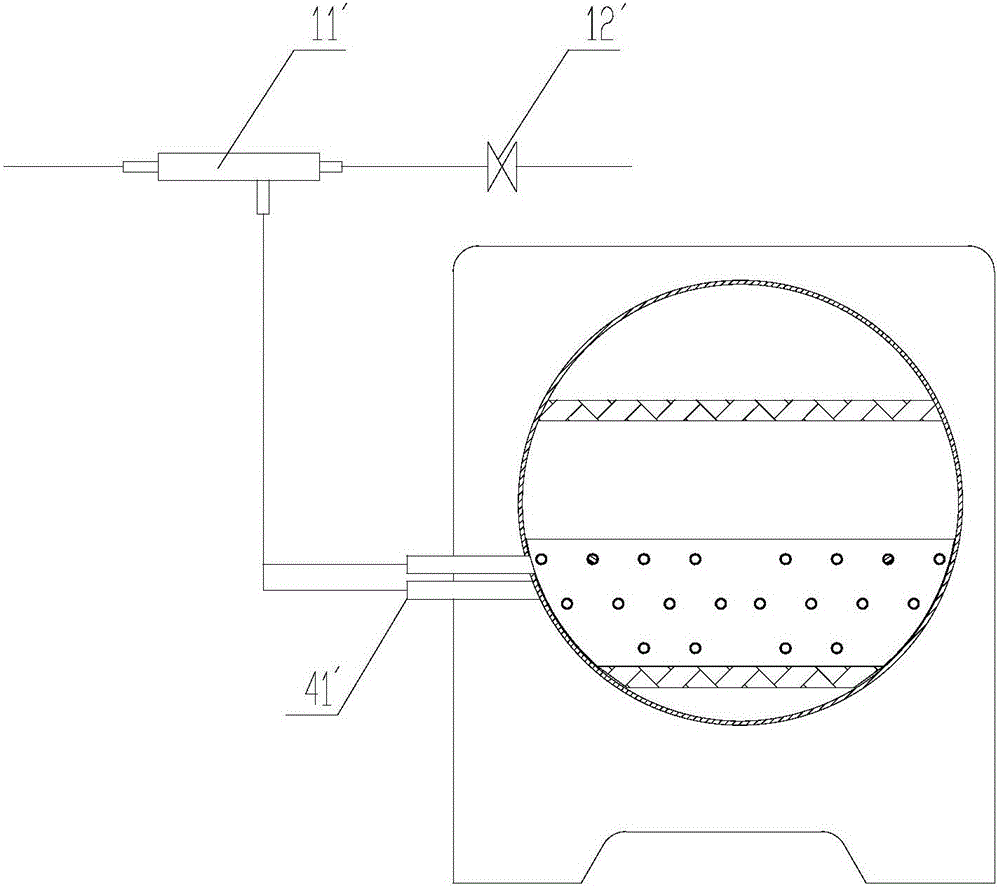

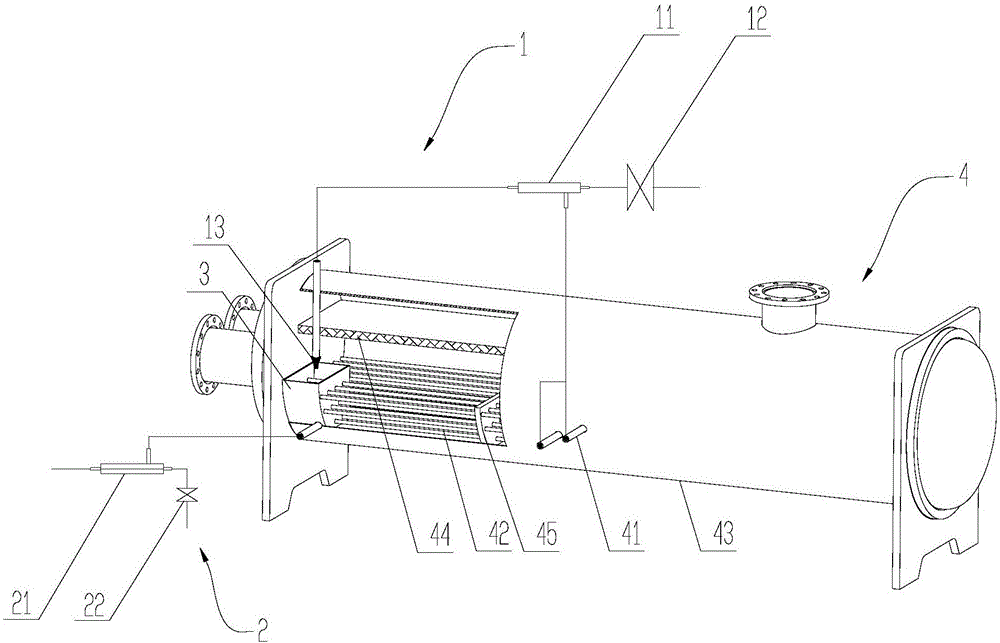

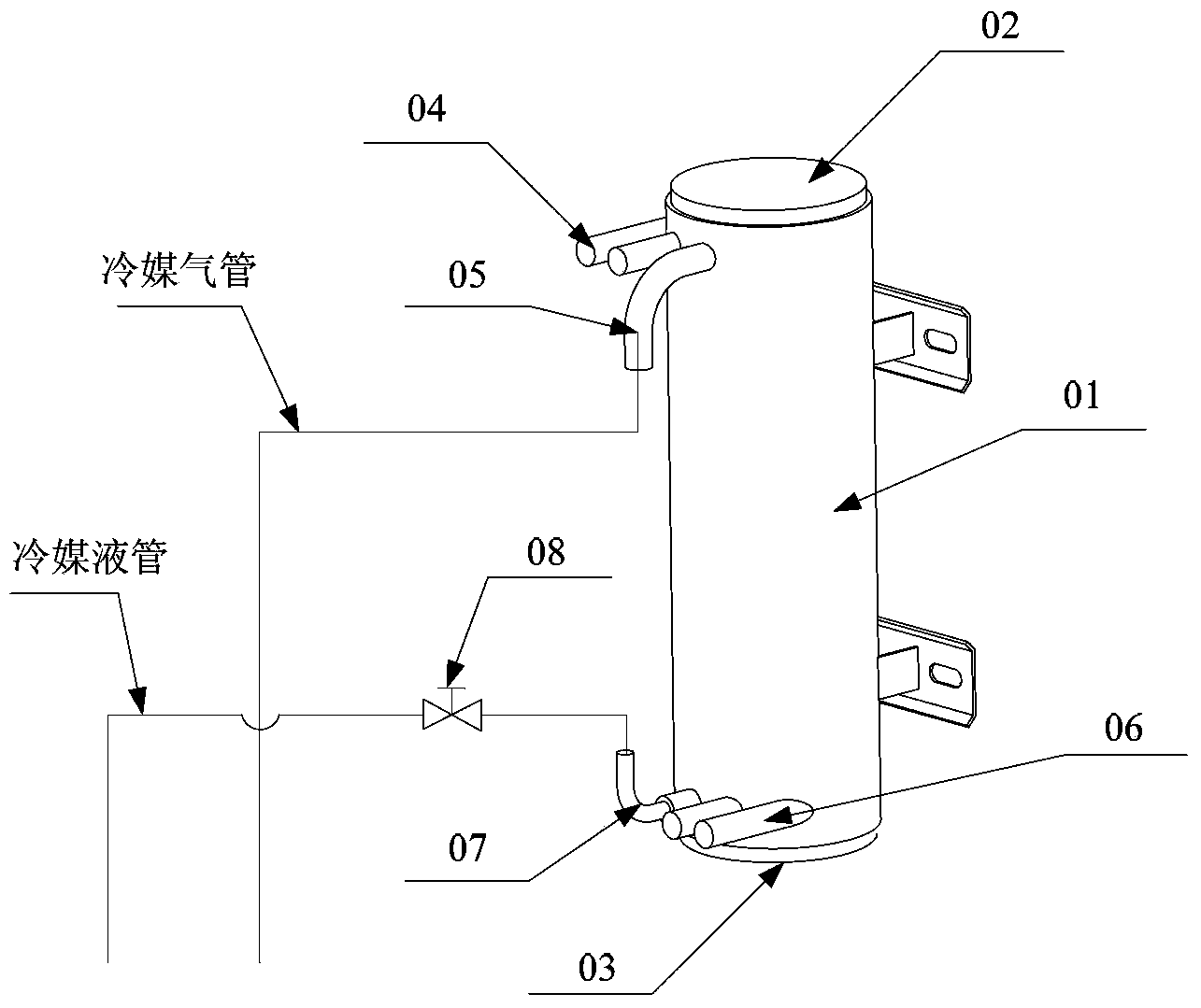

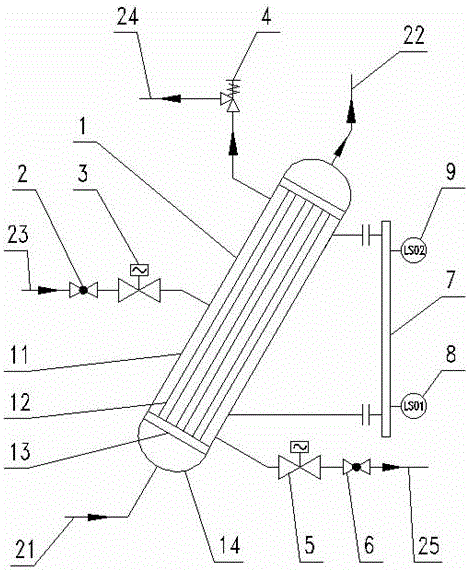

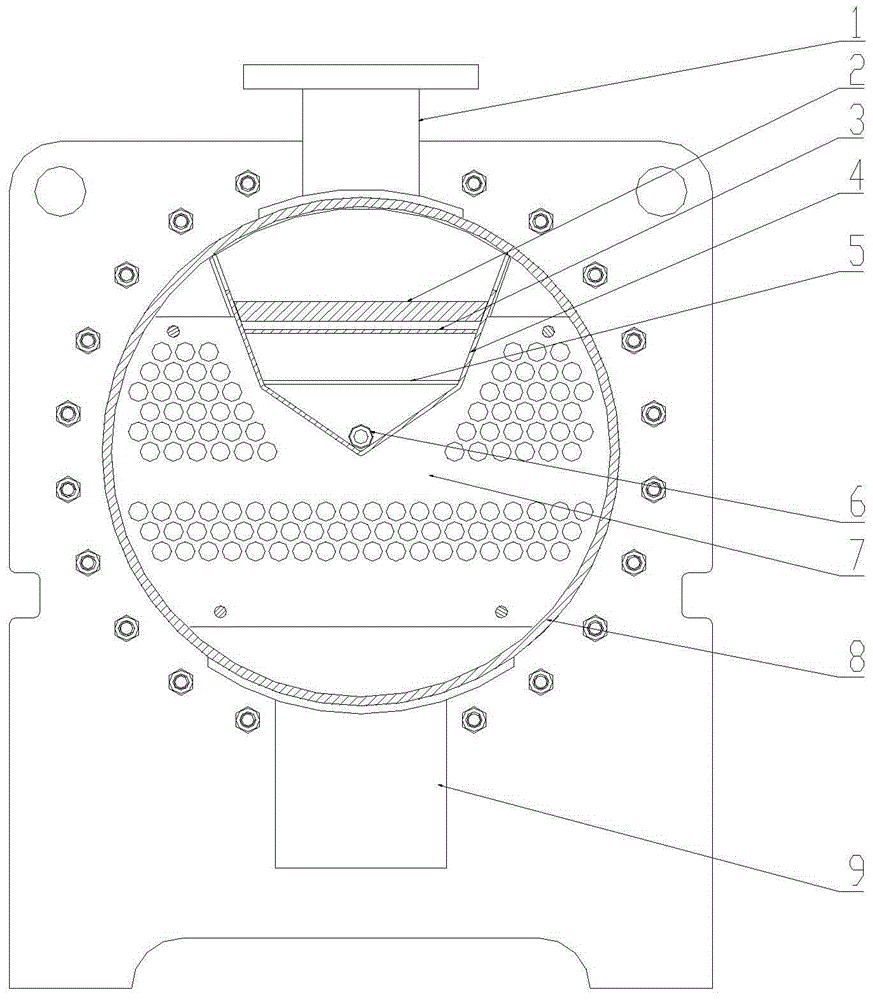

Oil return control system based on shell-and-tube heat exchanger

ActiveCN103486773AImprove oil return efficiencyEvaporators/condensersPlate heat exchangerShell and tube heat exchanger

The invention discloses an oil return control system based on a shell-and-tube heat exchanger. The oil return control system comprises a barrel, an oil chamber, a first solenoid valve, a second solenoid valve and a third solenoid valve, wherein the oil chamber is used for containing lubricating oil flowing from the bottom of the barrel; the first solenoid valve is used for controlling the pressure of the inner cavity of the oil chamber; the second solenoid valve is used for discharging the lubricating oil in the oil chamber into a refrigerant air pipe; the third solenoid valve is used for discharging the lubricating oil deposited on the bottom of the barrel into the oil chamber; the oil chamber is arranged below the bottom of the barrel; one end of the third solenoid valve is connected with a solenoid valve pipe orifice which is communicated with the inner cavity of the barrel and is formed in the side wall of the lower part of the barrel; the other end of the third solenoid valve is connected with a first pipe orifice formed in the side wall of the oil chamber; one end of the first solenoid valve is connected with a second pipe orifice formed in the bottom of the oil chamber; the other end of the first solenoid valve is connected with a refrigerant liquid pipe orifice formed in the side wall of the lower part of the barrel; one end of the second solenoid valve is connected with the first pipe orifice formed in the bottom of the oil chamber; the other end of the second solenoid valve is connected with a refrigerant air pipe orifice formed in the side wall of the upper part of the barrel. By using the oil return control system based on the shell-and-tube heat exchanger, the oil return efficiency is improved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Oil and gas separator, engine and automobile

InactiveCN103244237AImprove oil and gas separation efficiencyEmission reductionMachines/enginesCrankcase ventillationCyclonic separationCrankcase

The invention belongs to the technical field of automobile structures, and discloses an oil and gas separator, an engine and an automobile. The oil and gas separator comprises a first separating cavity and a second separating cavity; the first separating cavity is hermetically communicated with the second separating cavity; a plurality of labyrinth barrier sets are arranged in the first separating cavity to form labyrinth separating areas; the second separating cavity comprises a cyclone separating area so as to form a secondary oil and gas separating structure; and a first liquid outlet and a gas inlet of the oil and gas separator are formed on the first separating cavity, and a second liquid outlet and a gas outlet of the oil and gas separator are formed on the second separating cavity, so that oil and gas mixtures are fed into the labyrinth separating areas at first, and oil and gas in the oil and gas mixtures are coarsely separated from each other in the labyrinth separating areas and then are fed into the cyclone separating area to be finely separated from each other. The oil and gas separator, the engine and the automobile have the advantages that the oil and gas separating efficiency of the oil and gas separator is greatly improved, the problem of emission due to oil gas in a crankcase of an existing engine is solved, and accordingly the problem of emission of an existing automobile is solved.

Owner:GREAT WALL MOTOR CO LTD

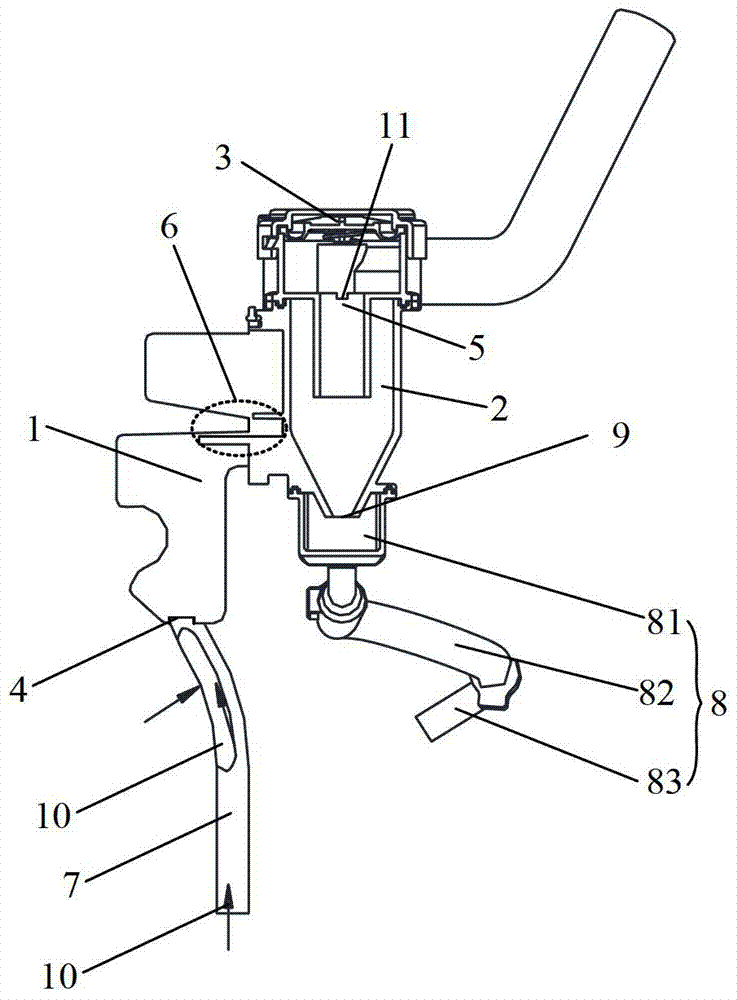

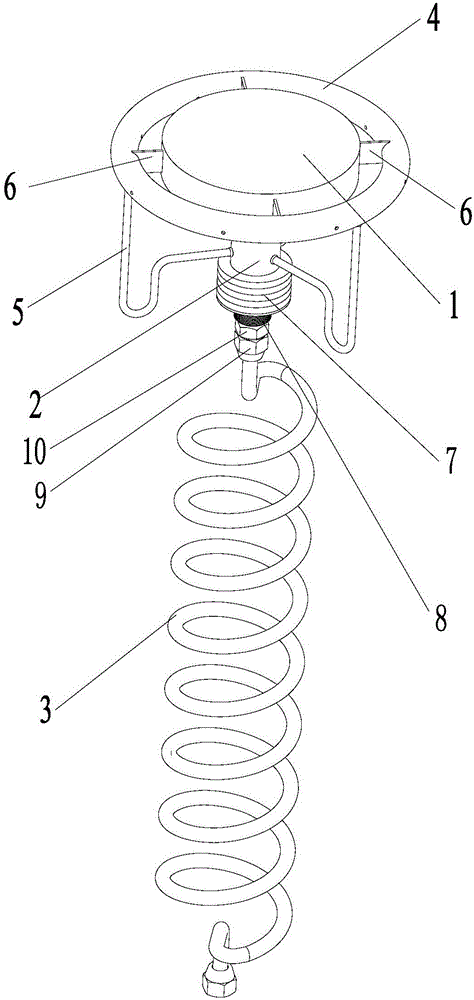

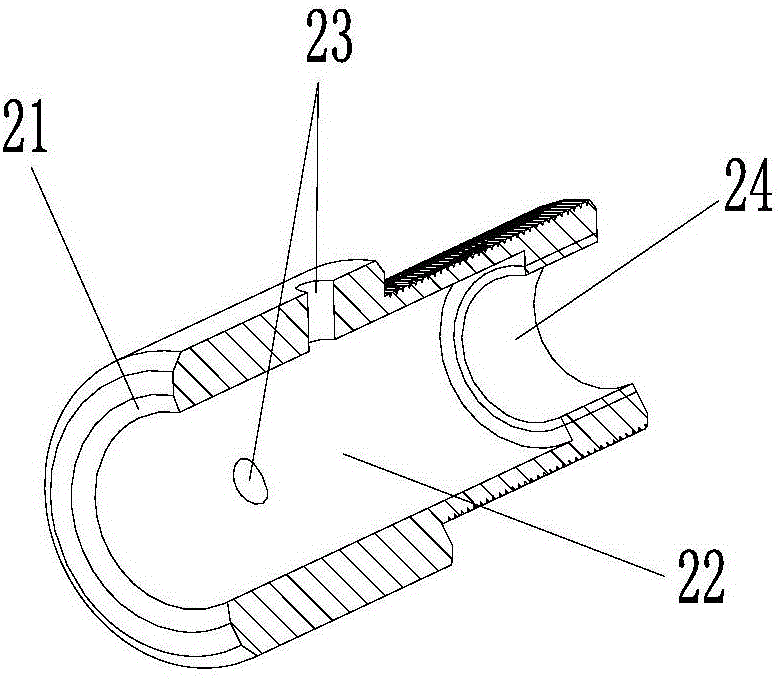

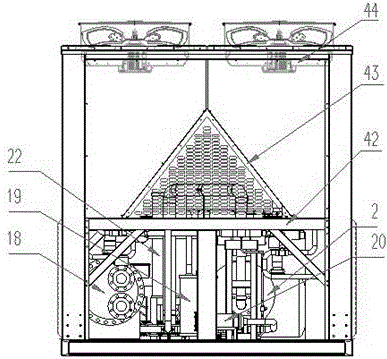

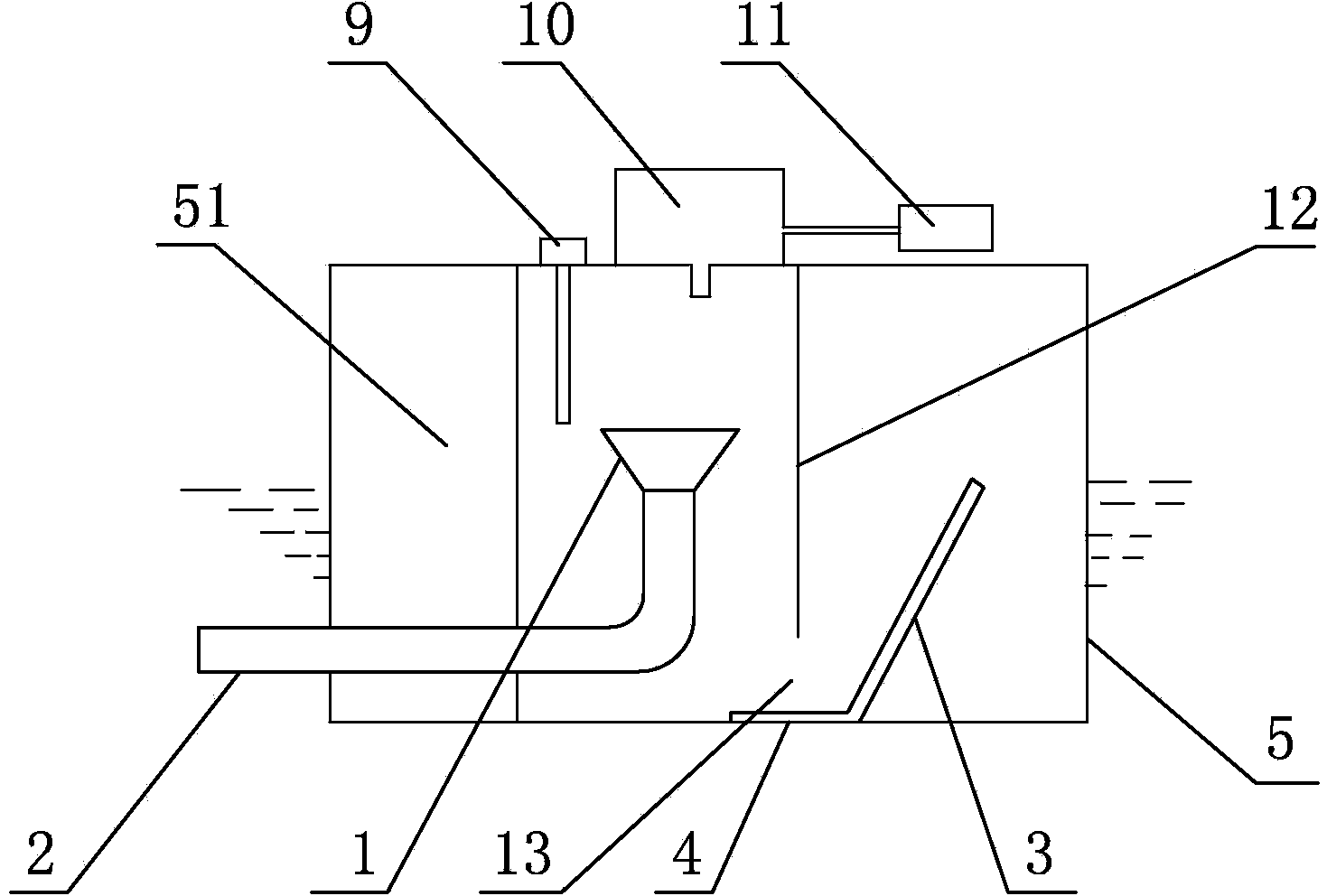

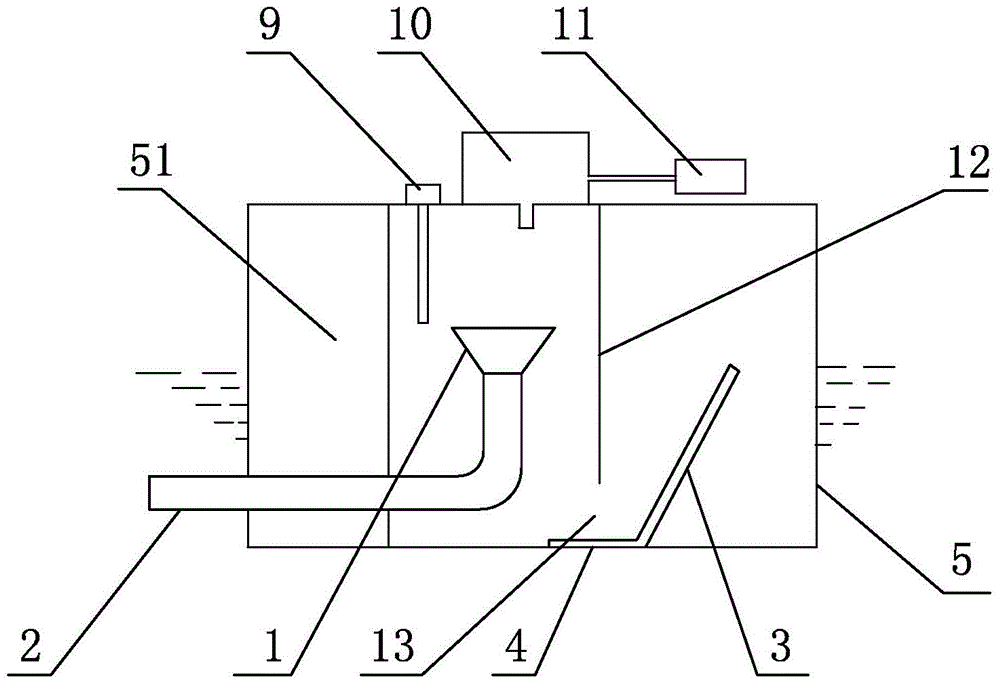

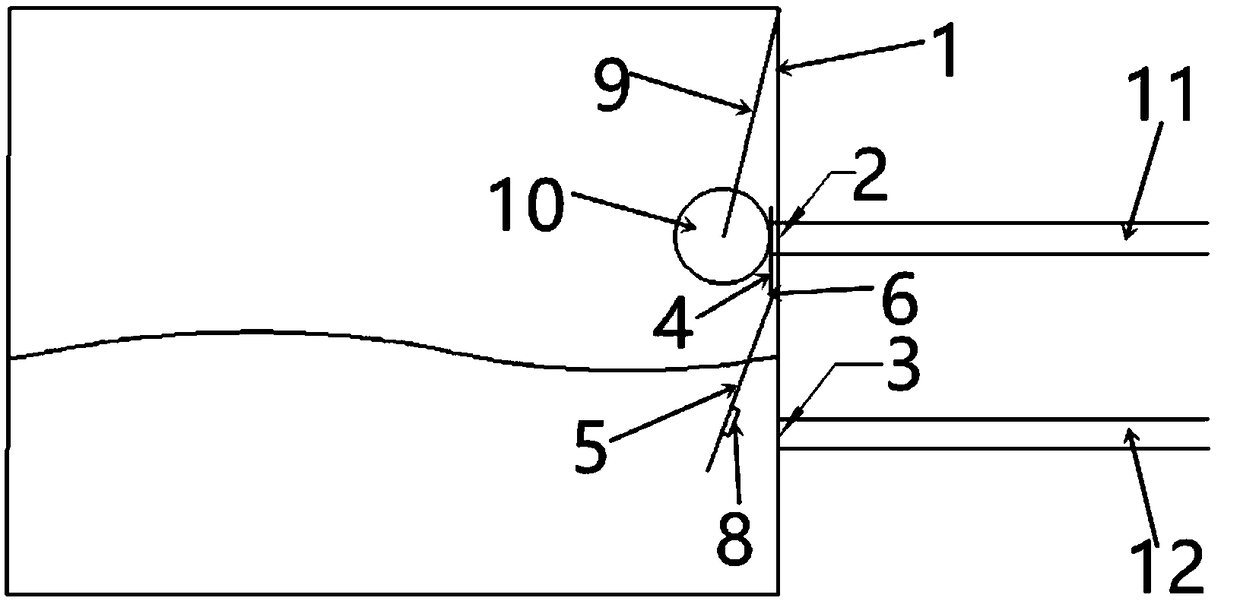

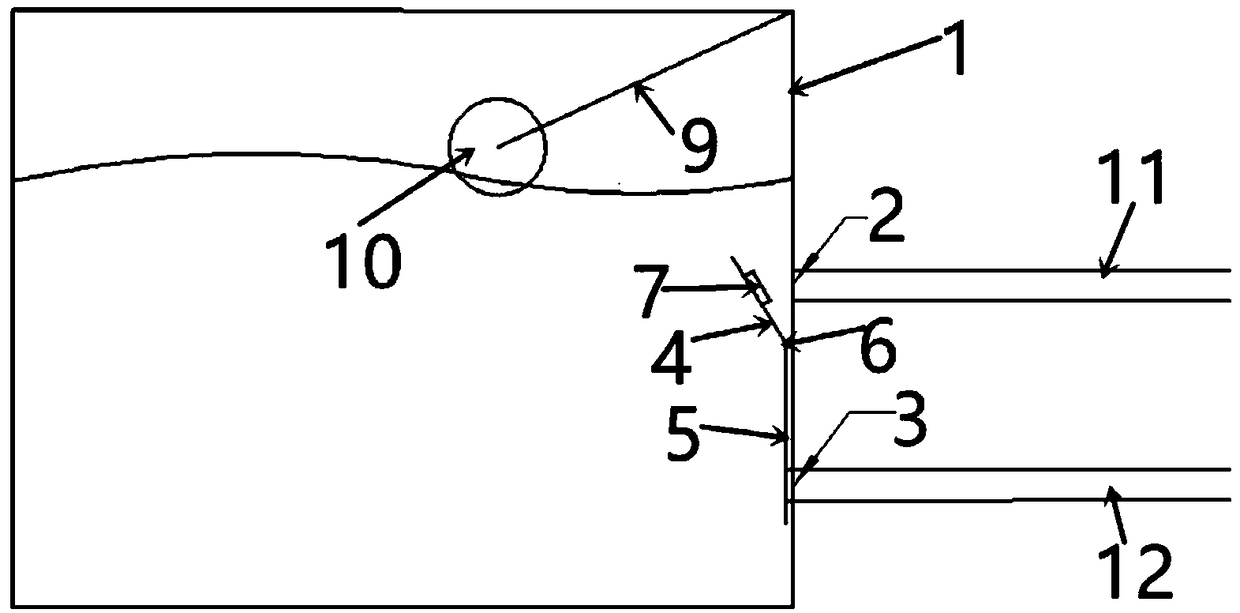

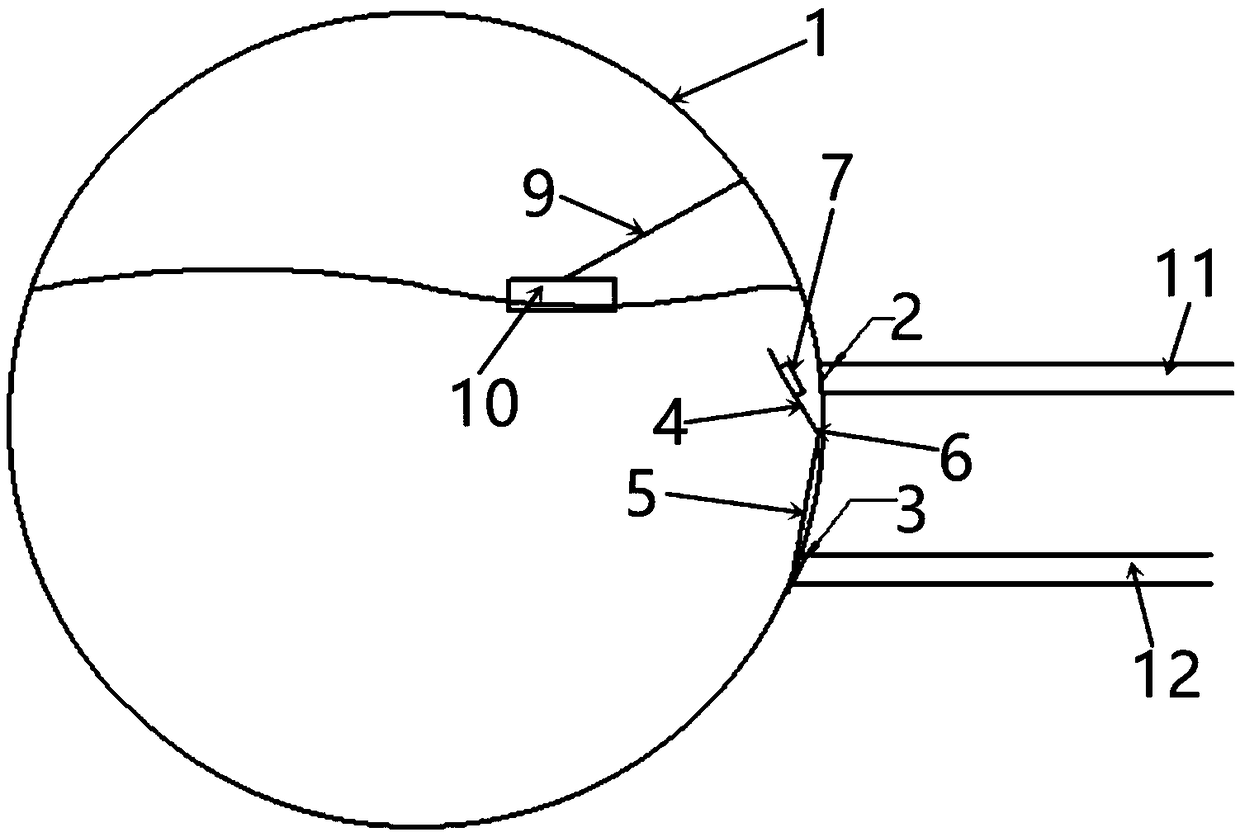

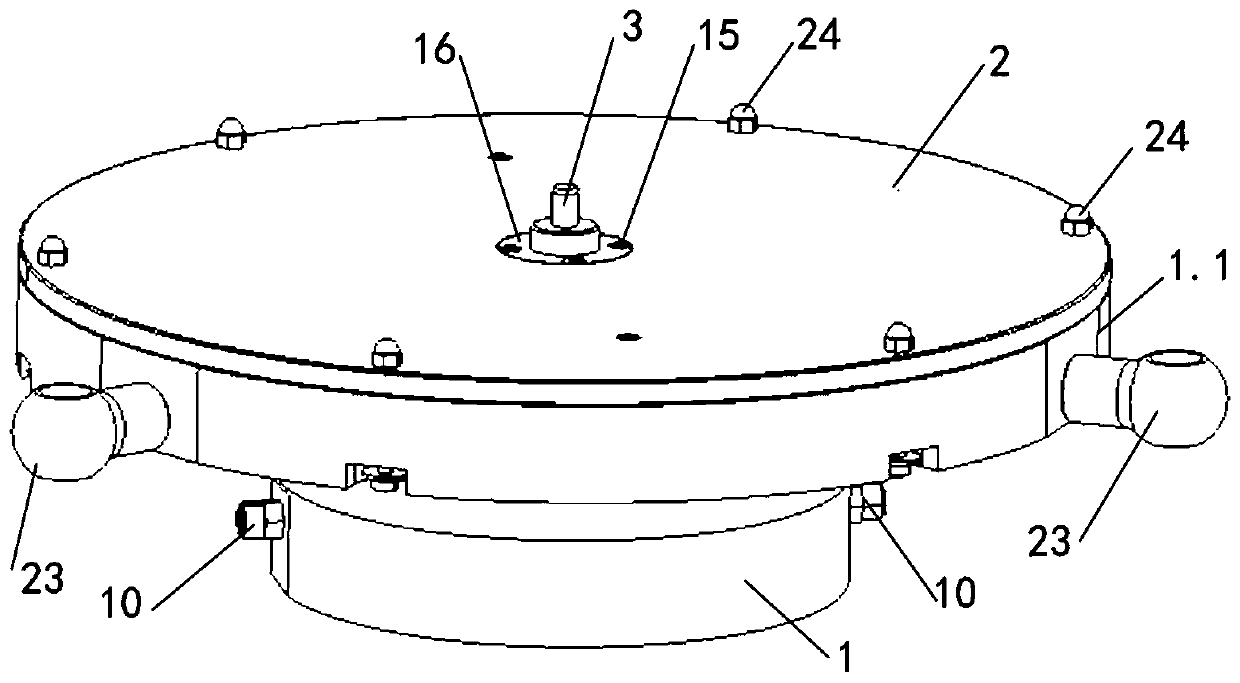

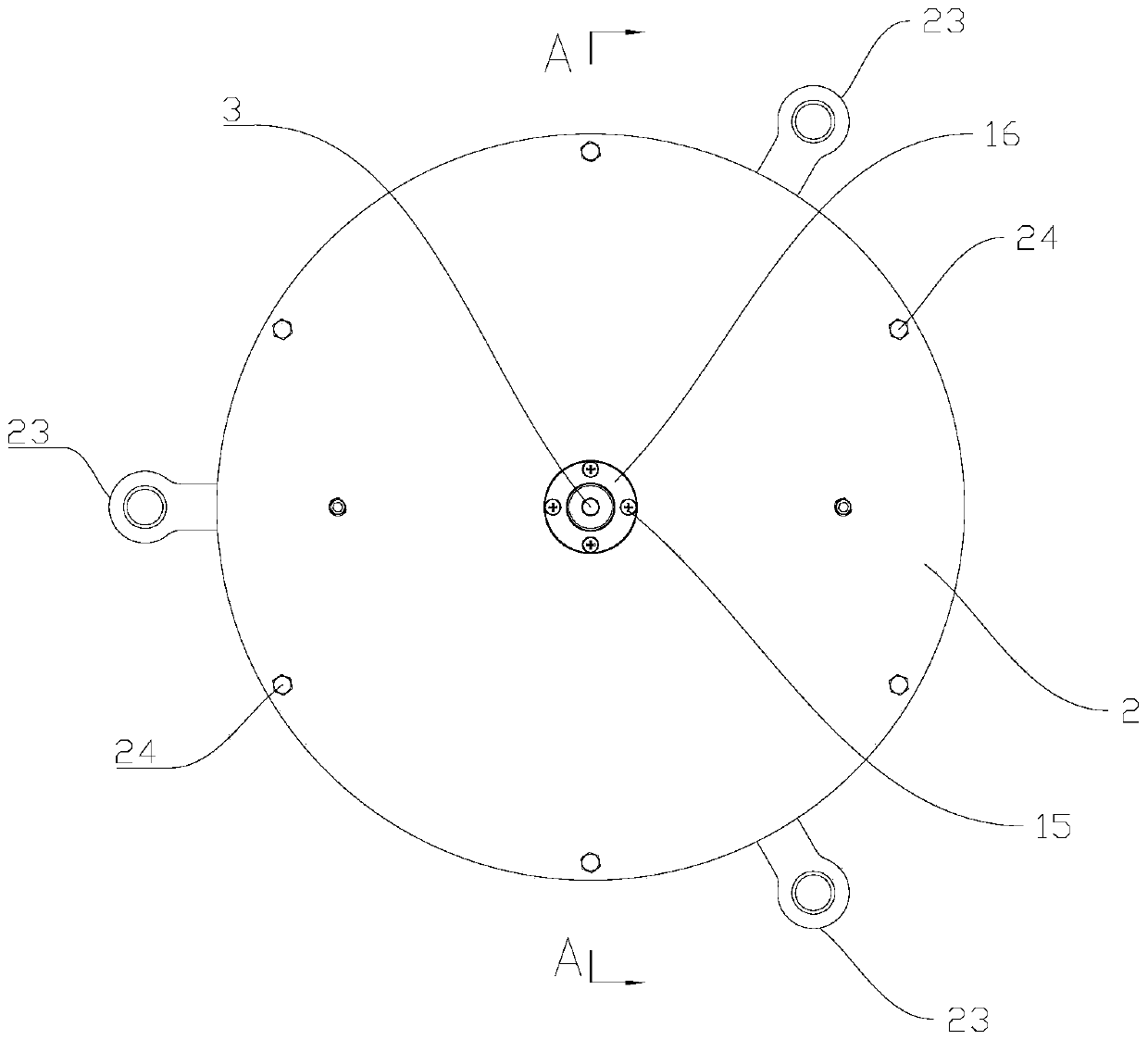

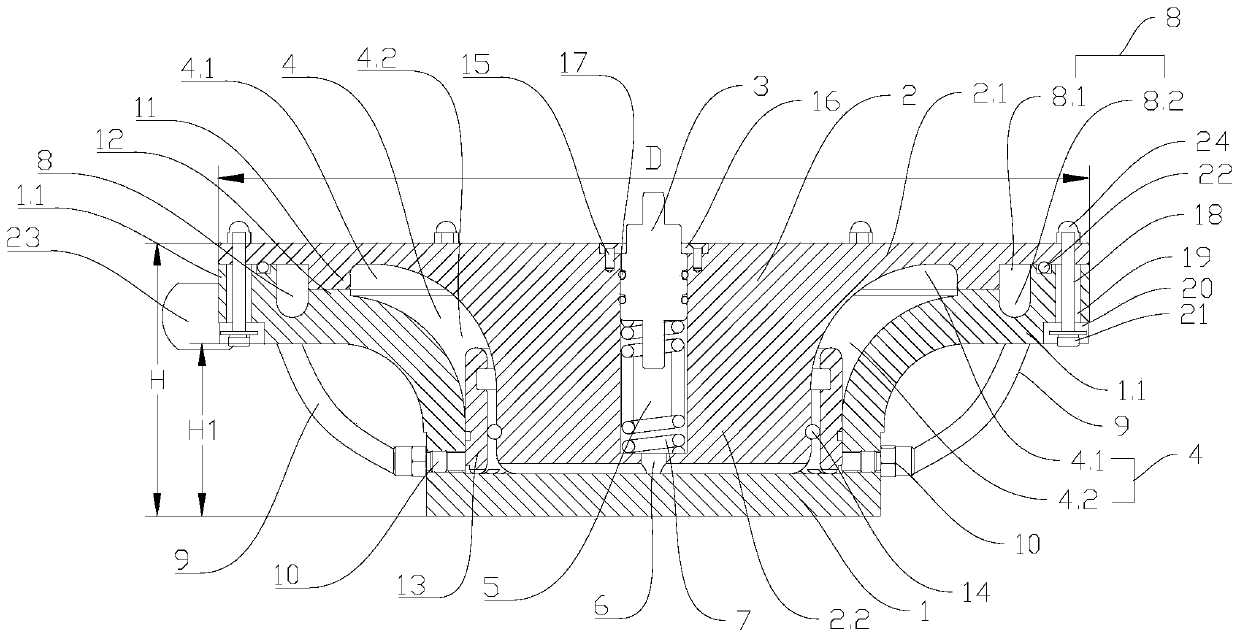

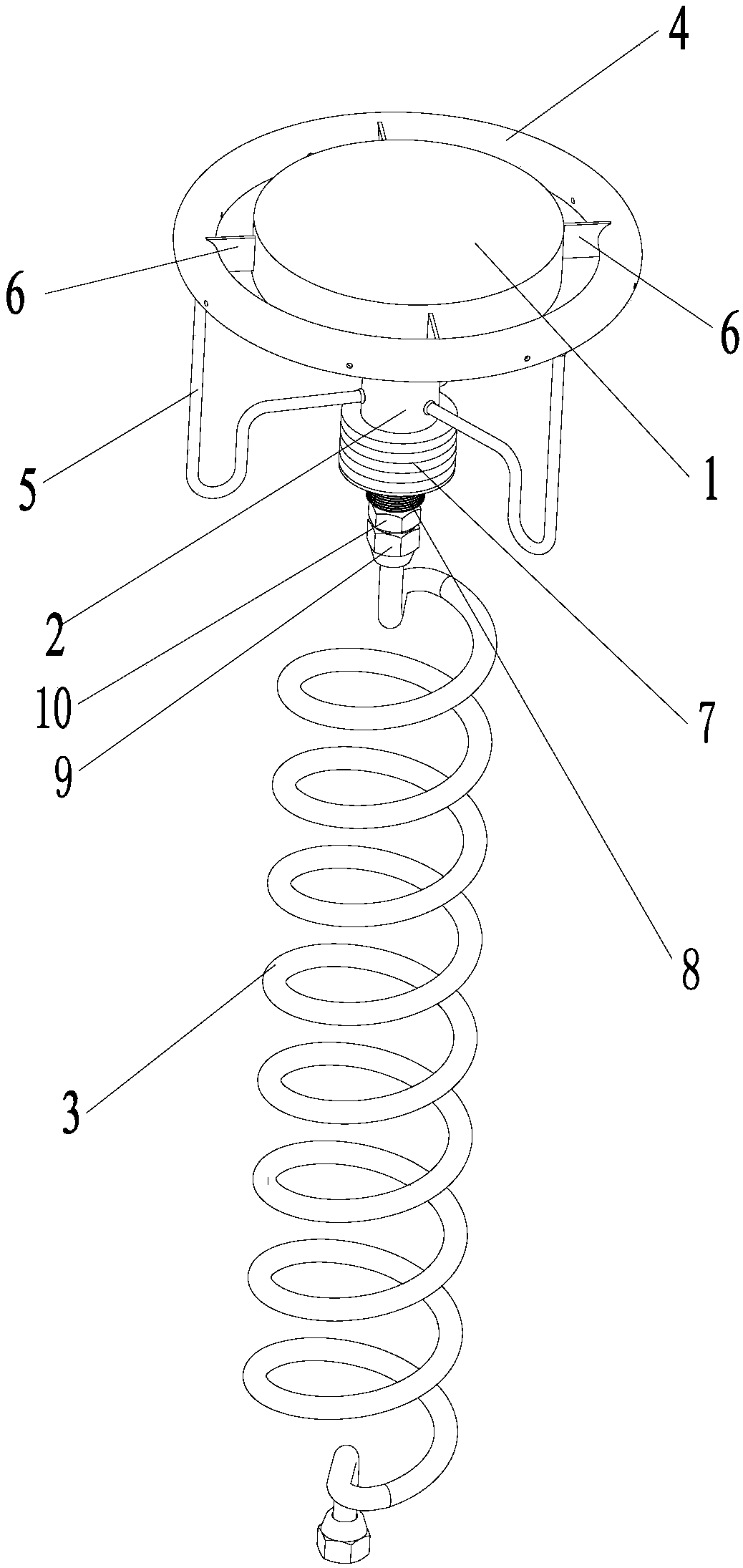

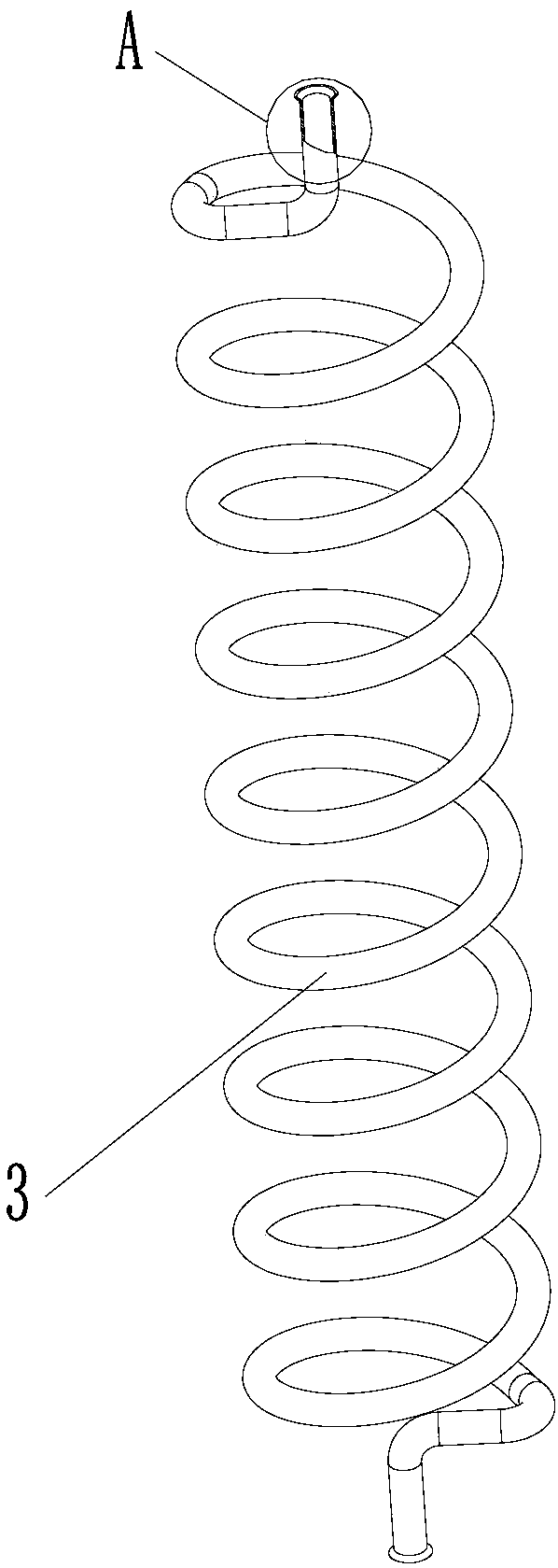

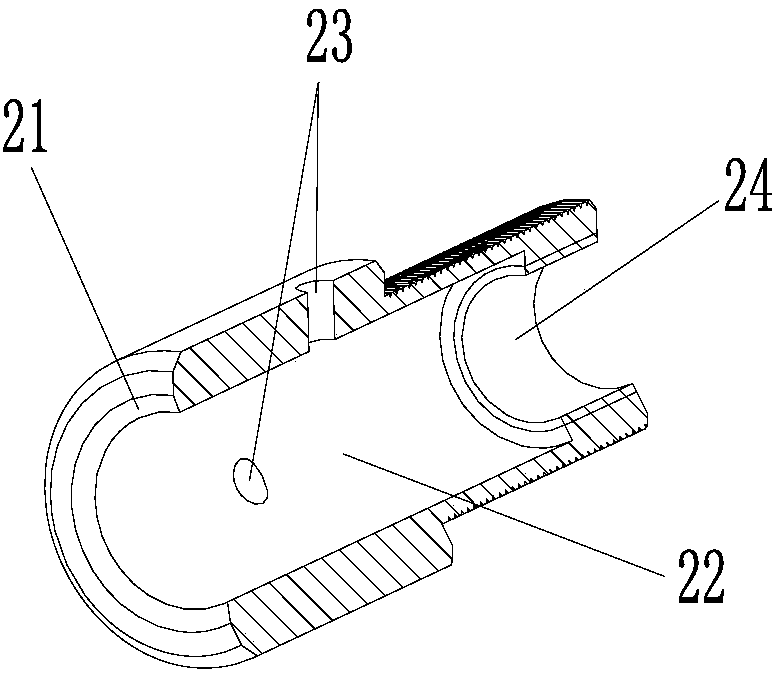

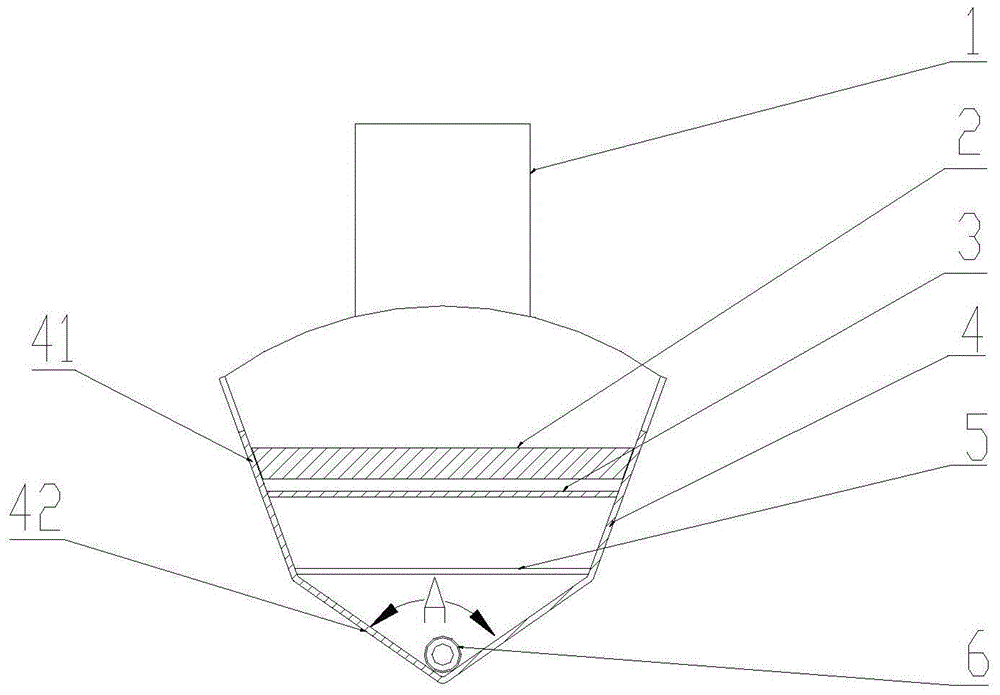

Oil return device and air-conditioning unit

The invention discloses an oil return device and an air-conditioning unit which belongs to the technical field of air conditioning and is designed to solve the problem of low oil return efficiency of the existing device. The invention relates to an oil return device, comprising an oil return assembly provided with a return port, a float, a heavy hammer and a return pipe, among which the oil return assembly is connected with the float, the upper end of the heavy hammer is connected with the float or the oil return assembly, the lower end is connected to the upper end of the oil return pipe, the oil return port communicates with the oil return pipe, and the oil return pipe can adjust its length in the vertical direction at least according to its force in the vertical direction. In that oil return device and the air-condition unit of the invention, the buoyancy and gravity balance principle are used, such that the oil return port can be accurately position in the vertical direction of the liquid surface of the oil-rich layer with the lowest height, so that the oil return is reliable, the oil return efficiency is improve, and the oil-free operation of the compressor is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

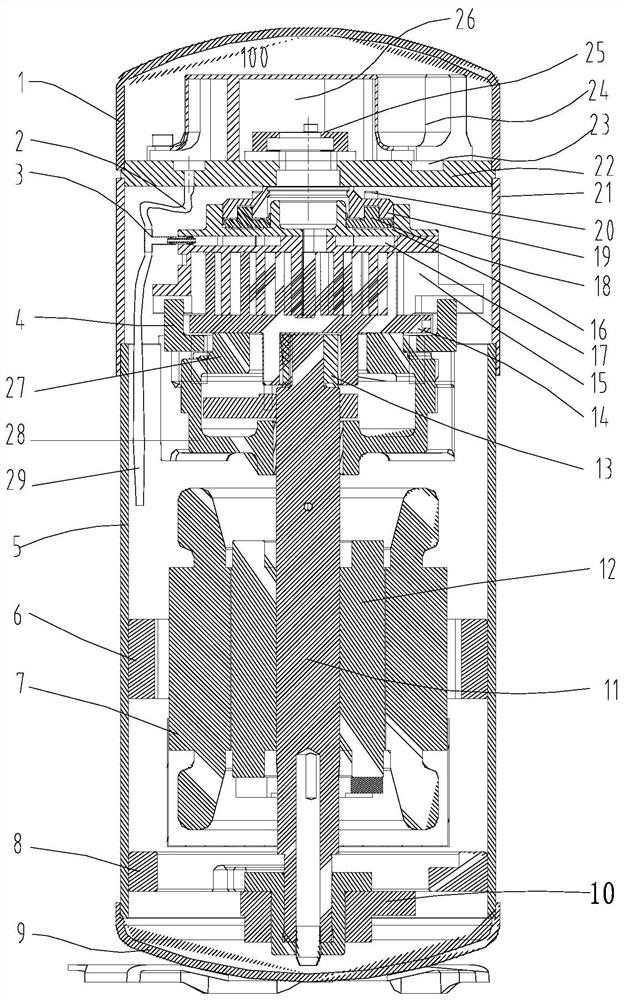

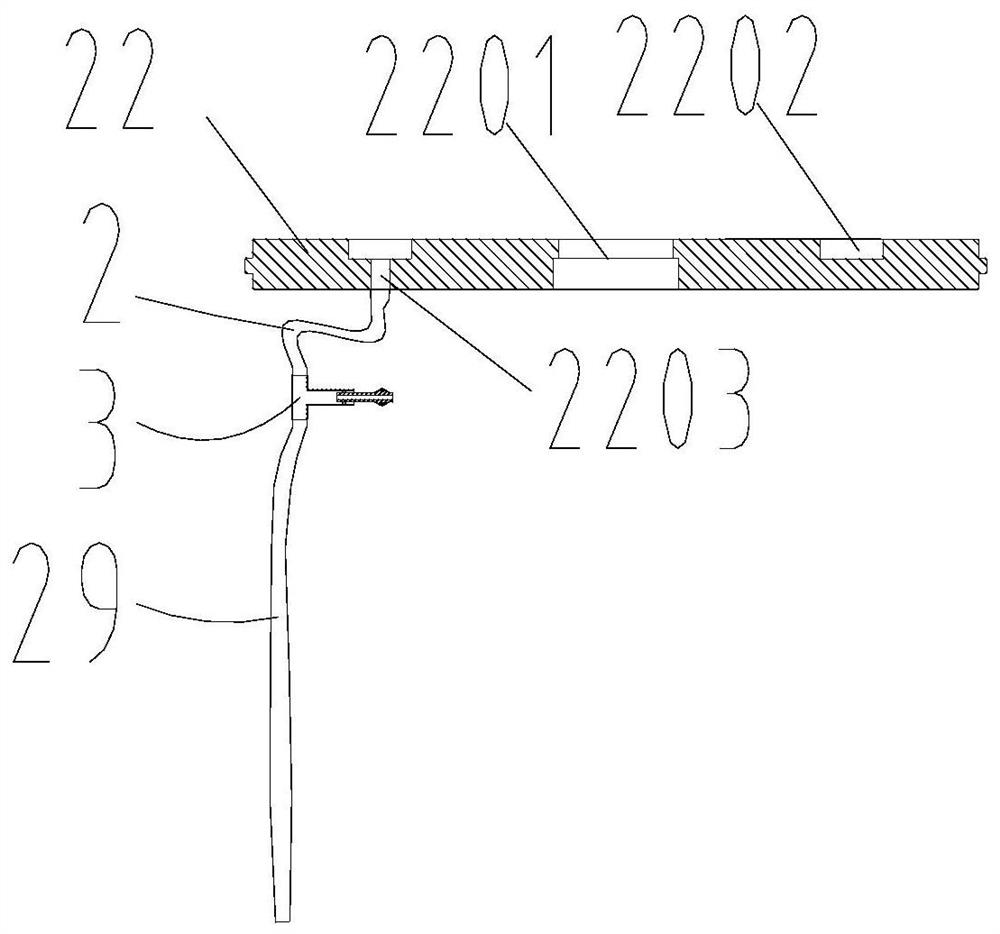

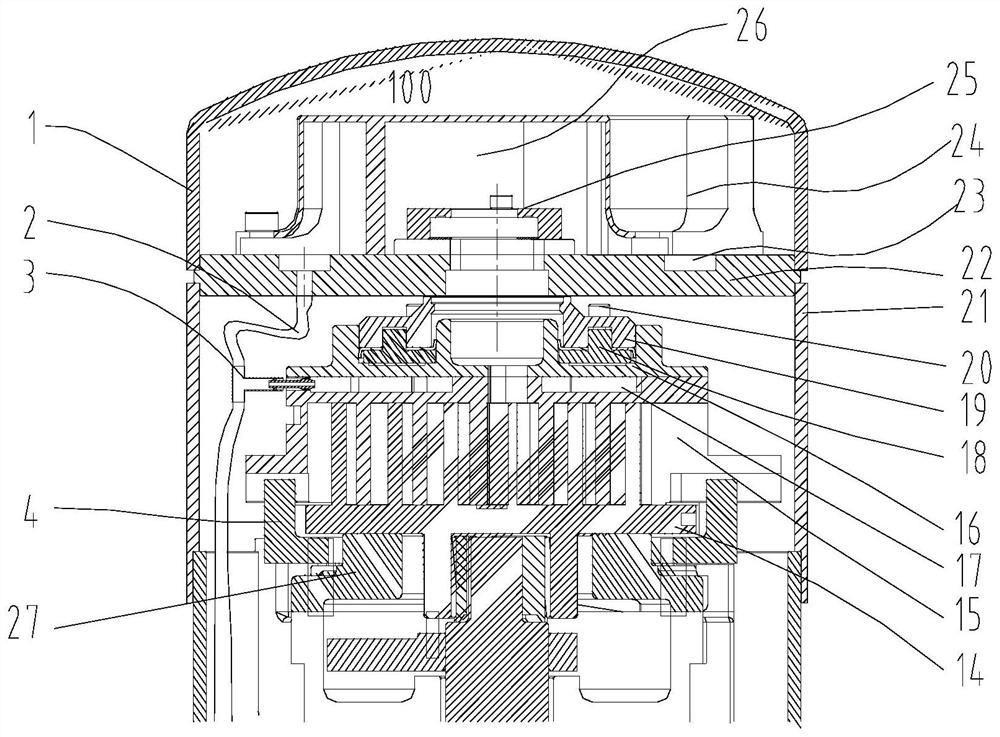

Compressor and air conditioner

ActiveCN112253457AIncrease oil returnImprove oil return efficiencyRotary piston pumpsRotary piston liquid enginesEngineeringOil supply

The invention provides a compressor and an air conditioner. The compressor comprises a static static scroll plate, a movable scroll plate and an oil return structure; the oil return structure can collect lubricating oil in exhausted gas; a static scroll plate cover board covers the side, back on to the movable scroll plate, of the static scroll plate; a first lubricating oil chamber is arranged onthe side, facing the static scroll plate cover board, of the static scroll plate, the oil return structure can guide collected lubricating oil into the first lubricating oil chamber, and a compression cavity can communicate with the first lubricating oil chamber; and / or a second lubricating oil chamber is arranged on the side, facing the static scroll plate, of the static scroll plate cover board, the oil return structure can guide collected lubricating oil into the second lubricating oil chamber, and the compression cavity can communicate with the second lubricating oil chamber. According tothe compressor and the air conditioner, oil obtained after oil and gas in the exhausted gas are separated can be effectively supplied to a pump body structure of the compressor, the oil return amountand the oil return efficiency are improved, the oil return effect is improved, the oil supply efficiency is high, the reliability is high, abnormal abrasion of a scroll plate of a scroll compressor is reduced, and noise is lowered.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

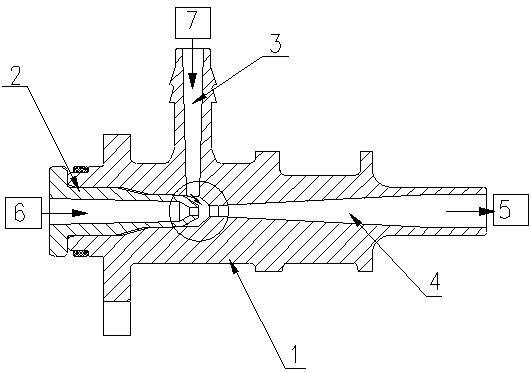

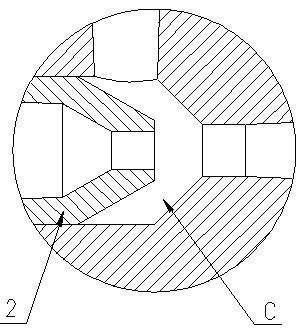

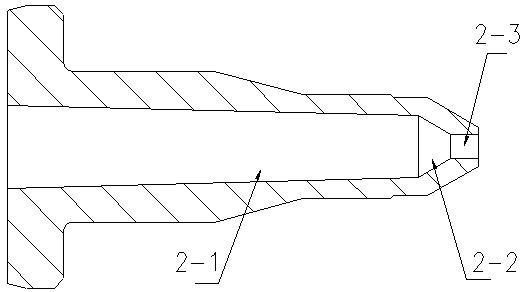

Negative-pressure structure easy for oil return of oil injector

InactiveCN102588176AImprove oil return efficiencyImprove working conditionFuel injection apparatusMachines/enginesInlet channelFuel tank

The invention discloses a negative-pressure structure easy for oil return of an oil injector, which is characterized in that the structure is composed of a negative-pressure structure body and a nozzle, the structure formed of the negative-pressure structure body and the nozzle enables a Venturi structure to be formed between the nozzle and the oil inlet channel of the oil tank; the retun oil of the oil injector can be extracted by means of the negative pressure brought about by the Venturi structure. The negative-pressure structure of the invention has the following beneficial effects: the efficiency for discharging residual oil in an oil injector assembly is effectively improved, and the oil injector assembly is ensured to be in a good working state, so as to improve the working condition of an engine.

Owner:CHONGQING FUEL INJECTION SYST CO LTD OF CHINA NAT HEAVY DUTY TRUCK GRP

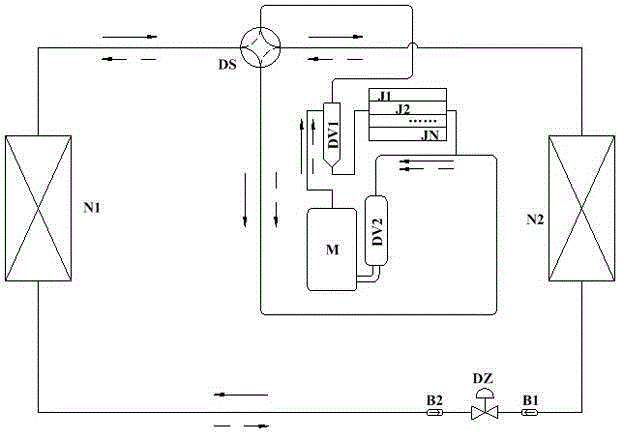

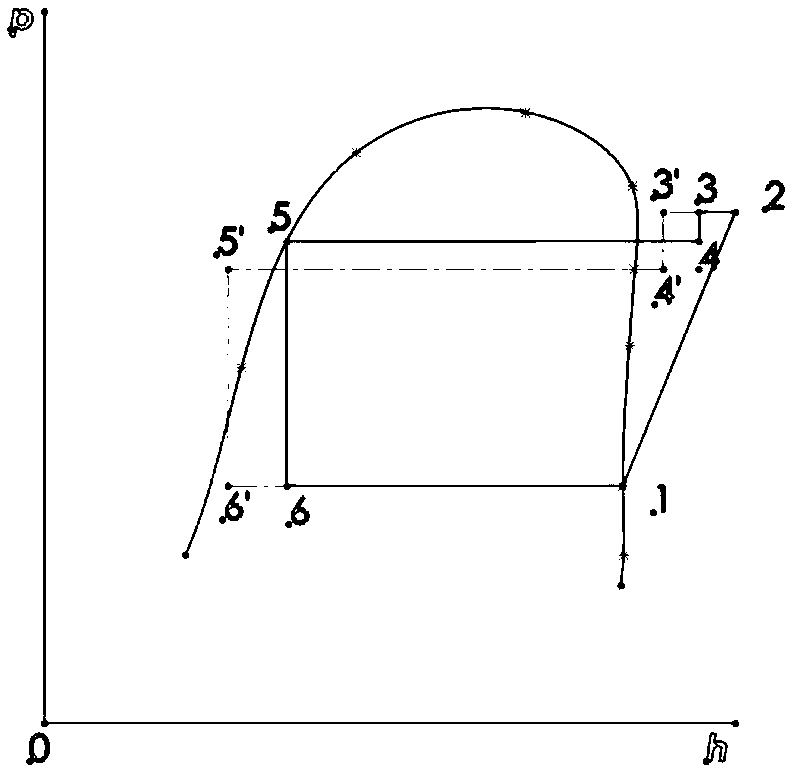

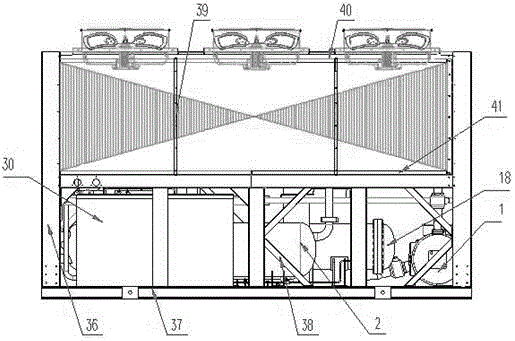

Anti-vibration type air cooled heat pump flooded water chilling unit and control method thereof

ActiveCN106524559AStable oil returnOil return safetyCompressorMechanical apparatusOperational systemVapor–liquid separator

The invention discloses an anti-vibration type air cooled heat pump flooded water chilling unit and a control method thereof. The anti-vibration type air cooled heat pump flooded water chilling unit comprises an electric case, a condenser, a compressor, a secondary oil separator, a four-way reversing valve, a finned heat exchanger, a liquid separator, expending valves, a one-way valve, a liquid reservoir, a drying and filtering device, electromagnetic valves, a flooded evaporator, a gas-liquid separator and a jet pump. According to the anti-vibration type air cooled heat pump flooded water chilling unit, return oil of one way of the secondary oil separator and return oil of the flooded evaporator are subjected to intelligent control, and meanwhile unit axial flow fans are subjected to hierarchical control, so that the problems that oil throwing occurs in the process of starting the compressor, the return oil is not stable in the operational process and a low-temperature refrigeration operational system is not stable are avoided. Thus the unit can continuously run under the whole year environment, provide sufficient circulating cooling water for a device and ensure that the device can run normally and safely.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

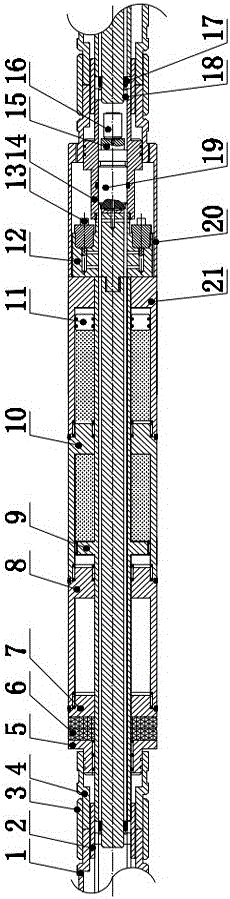

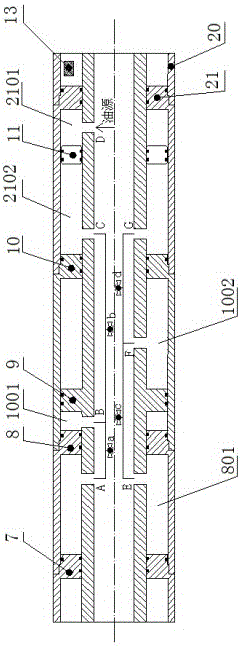

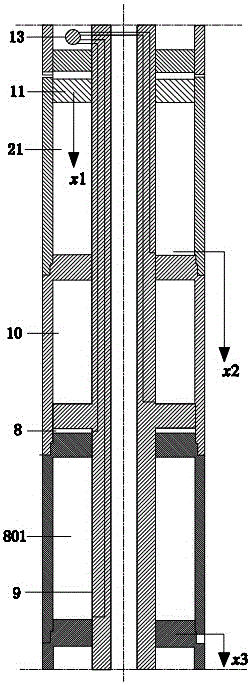

Novel active hydraulic control packer

ActiveCN105909205AEasy to processReduce manufacturing costSealing/packingHydraulic cylinderControl engineering

The invention discloses a novel active hydraulic control packer. A push hydraulic cylinder, an action hydraulic cylinder and a power hydraulic cylinder which are in threaded connection with one another are arranged on a core shaft in sequence; the oil supply end of an axial plunger pump communicates to a right cavity of the power hydraulic cylinder; an oil path I, an oil path II, an oil path III and an oil path IV are formed in the core shaft; electronic valves controlled by a controller to be opened and closed are respectively arranged on the four oil paths; the left cavity of the power hydraulic cylinder communicates to the left cavity of the action hydraulic cylinder through the oil path I; the right cavity of the action hydraulic cylinder communicates to the vacuum cavity of the push hydraulic cylinder through the oil path II; the left cavity of the power hydraulic cylinder communicates to the right cavity of the action hydraulic cylinder through the oil path III; the left cavity of the action hydraulic cylinder communicates to the vacuum cavity of the push hydraulic cylinder through the oil path IV. The novel active hydraulic control packer comprises a multi-cylinder combination driving module, a pump valve integration module, a core shaft oil path channel, a vacuum cavity setting and the like, so that the complexity of the packer is reduced, and the reliability of a system is improved.

Owner:MUDANJIANG XINXIANG PETROLEUM MASCH CO LTD

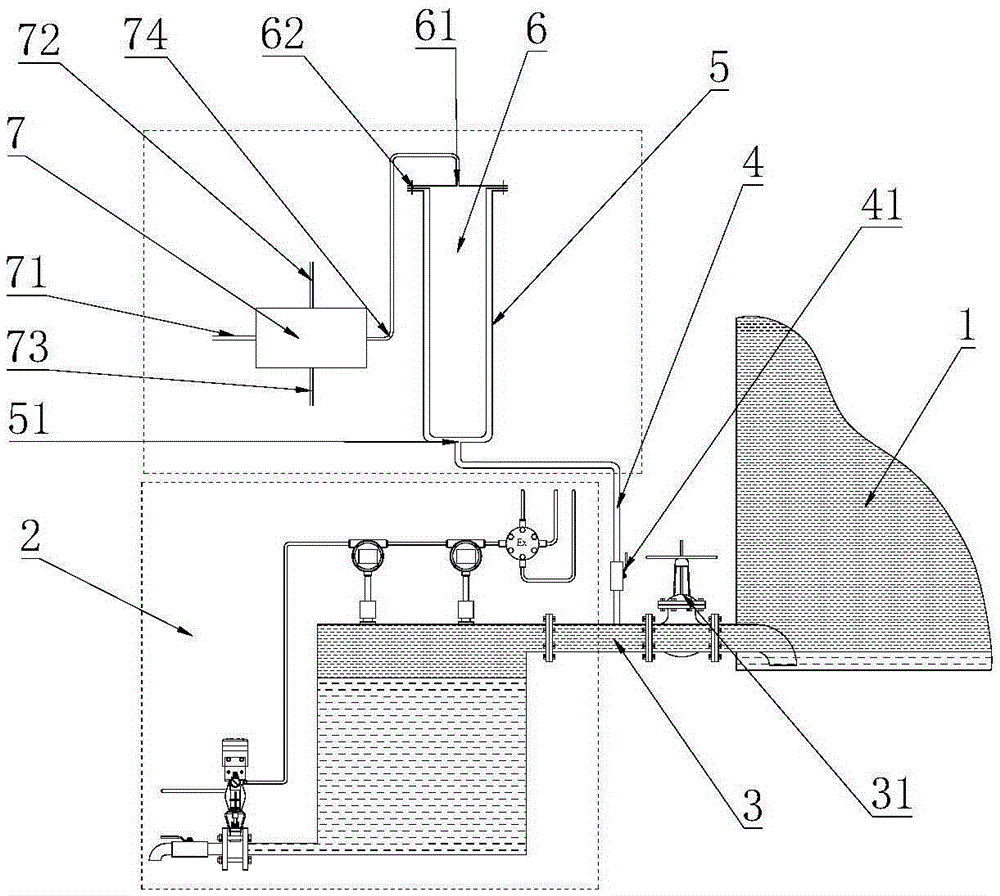

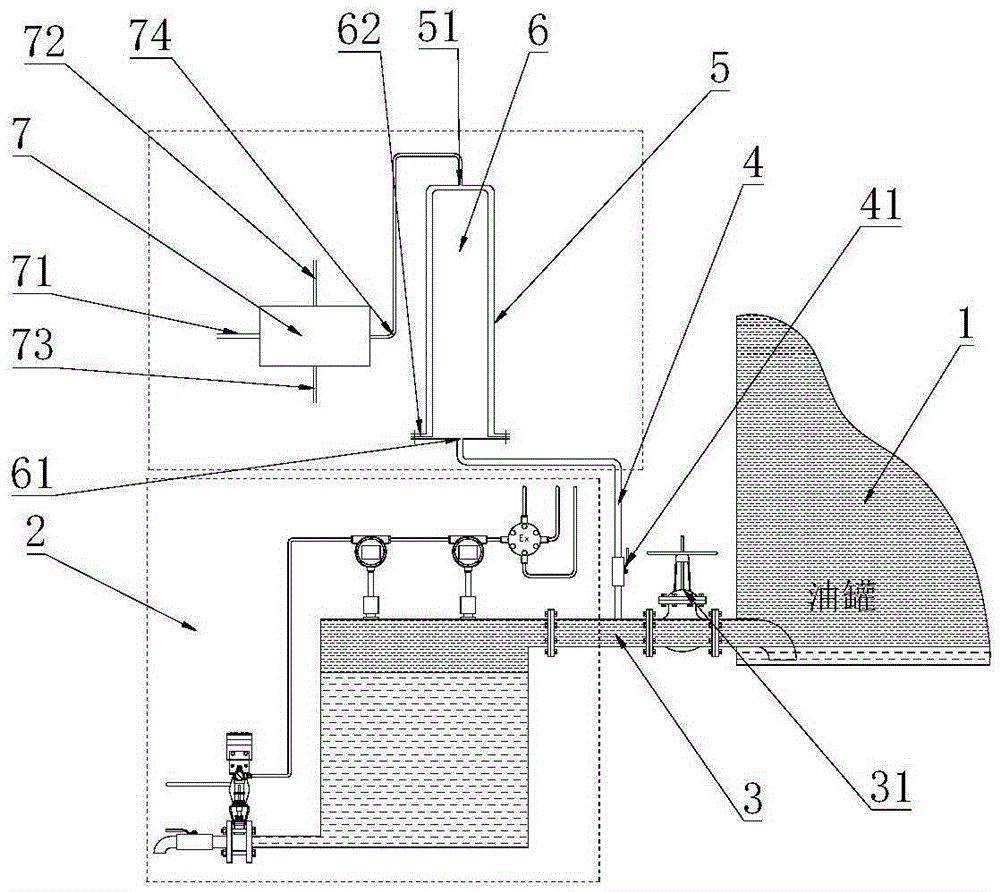

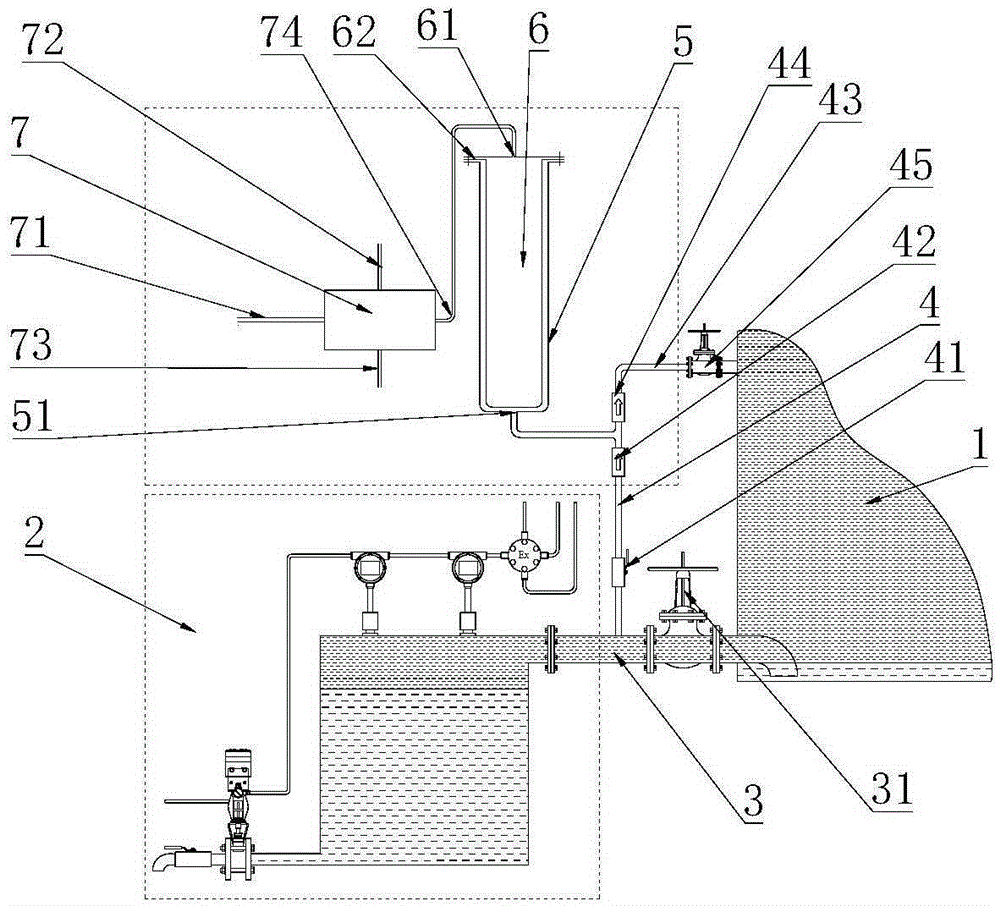

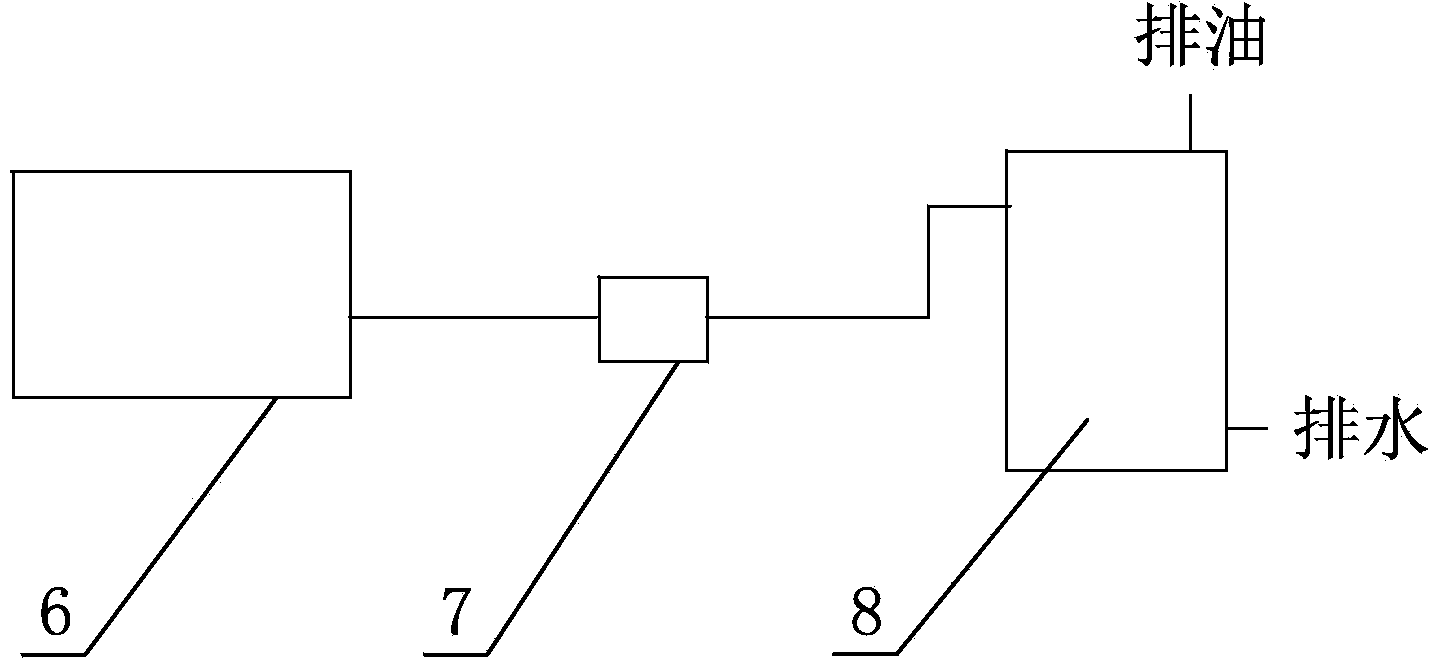

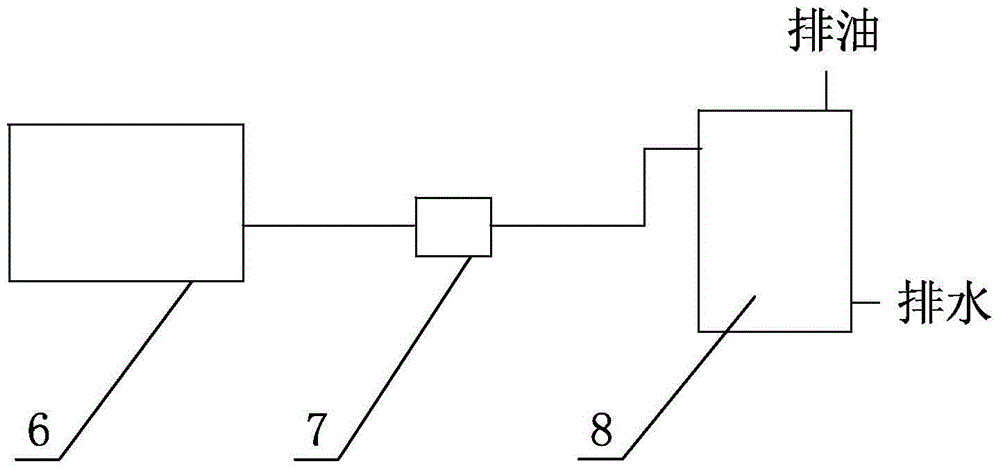

Automatic dehydrating and oil returning system for siphoning type oil tank and oil returning method

ActiveCN105416893AImprove oil return efficiencyAvoid damageLarge containersLiquid separationBuffer tankWaste management

The invention discloses an automatic dehydrating and oil returning system for a siphoning type oil tank and an oil returning method. The automatic dehydrating and oil returning system comprises an oil tank, a dehydrator, a dehydrating pipeline for connecting the oil tank and the dehydrator and an oil returning system, wherein the oil returning system is connected with the dehydrating pipeline through a connecting pipeline; a connecting hole of the connecting pipeline and the dehydrating pipeline is formed in the top wall of the dehydrating pipeline; the oil returning system is composed of a buffer tank, a soft capsule and a controlling device; an inflation cavity and an inflation hole are formed in the soft capsule; the buffer tank seals the soft capsule in a tank body of the buffer tank; a gas outlet is formed in the buffer tank; and the controlling device is connected with the inflation cavity of the soft capsule or the gas outlet of the buffer tank. According to the automatic dehydrating and oil returning system disclosed by the invention, oil is isolated from air through the soft capsule and the sealed buffer tank, the deformation characteristics of the soft capsule is utilized, and the oil returning system is controlled to suck or discharge oil by changing the pressure in the soft capsule without a limitation of speed, so that the automatic dehydrating and oil returning system improves the oil returning efficiency and is safe and environment-friendly.

Owner:GUANGZHOU DAY WO AUTOMATION IND

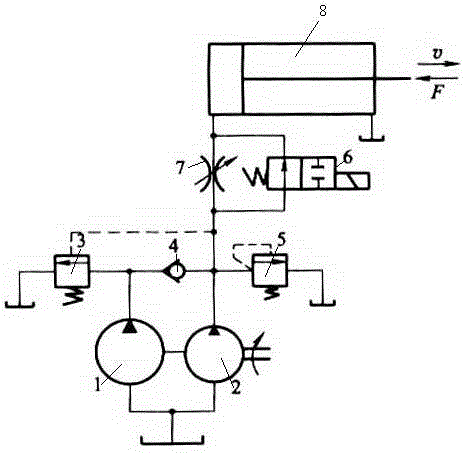

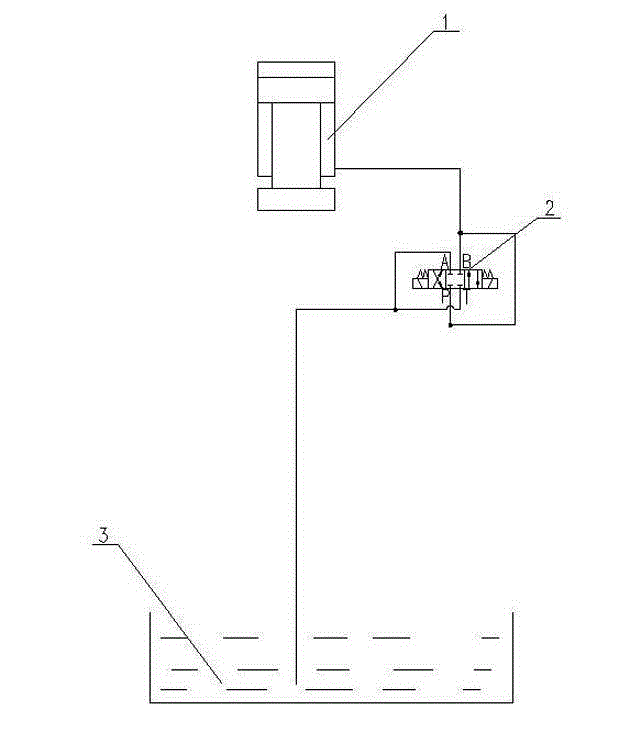

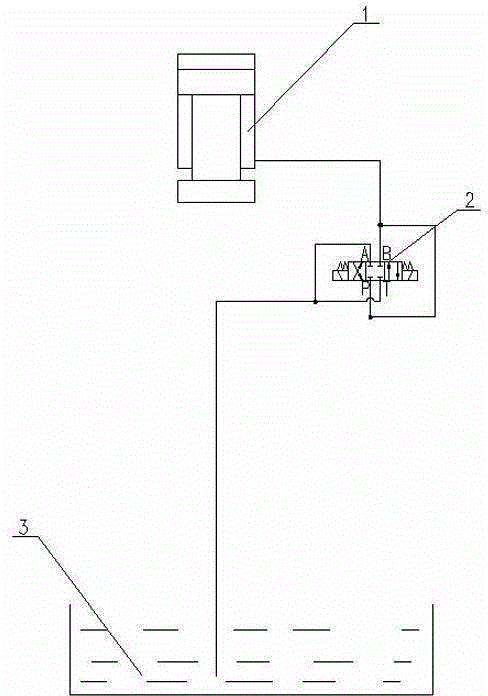

Double-pump oil supply fast-control system

InactiveCN104061198AImprove oil return efficiencyEasy to useServomotor componentsServomotorsHydraulic cylinderControl system

The invention discloses a double-pump oil supply fast-control system. The double-pump oil supply fast-control system comprises a hydraulic cylinder and is characterized by also comprising a low-pressure large-flow pump, a high-pressure small-flow pump, a reversing valve and a throttling valve, wherein the high-pressure small-flow pump is connected with the hydraulic cylinder by a pipeline on which the throttling valve is arranged; the pipelines on two sides of the throttling valve are connected with the reversing valve; the low-pressure large-flow pump is connected with a pipeline for connecting the high-pressure small-flow pump and the hydraulic cylinder by a branch pipeline on which a one-way valve is arranged. The double-pump oil supply fast-control system disclosed by the invention has the advantages that the problems that the hydraulic cylinder adopts a single pump for supplying oil generally, the application range is smaller, the use effect is poorer, the oil returning efficiency is poorer, the power consumption is higher, and the use need cannot be met in the prior art are solved; the structure is simple, the use is convenient, a duplex pump can be provided as a power source, the power consumption is less, the oil returning efficiency is higher, and the use is safer and more reliable.

Owner:SUZHOU HUALAI PHOTOELECTRIC INSTR

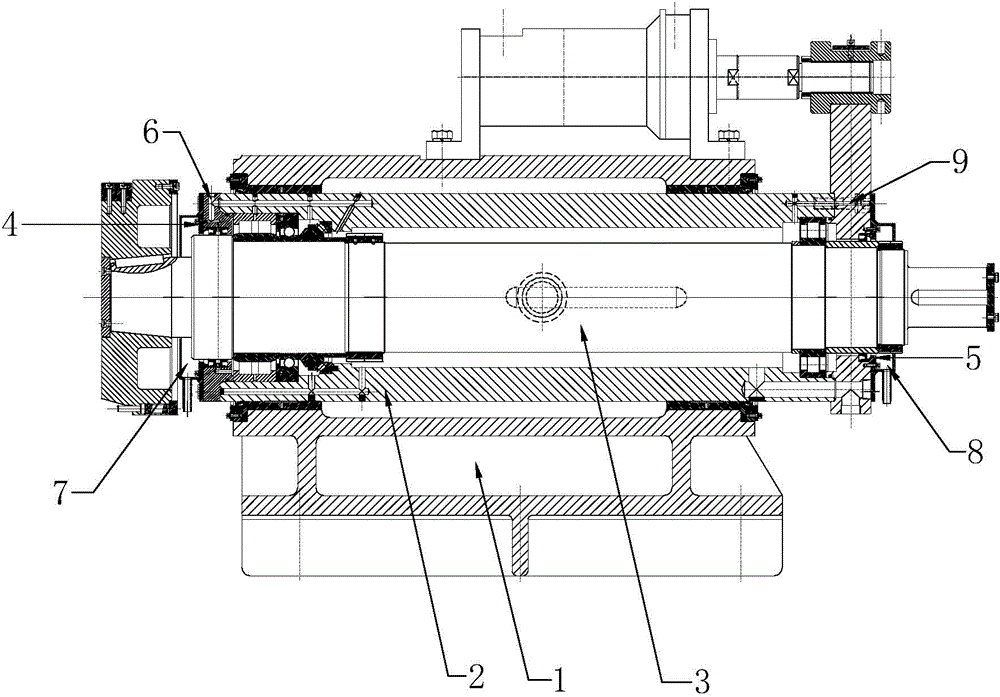

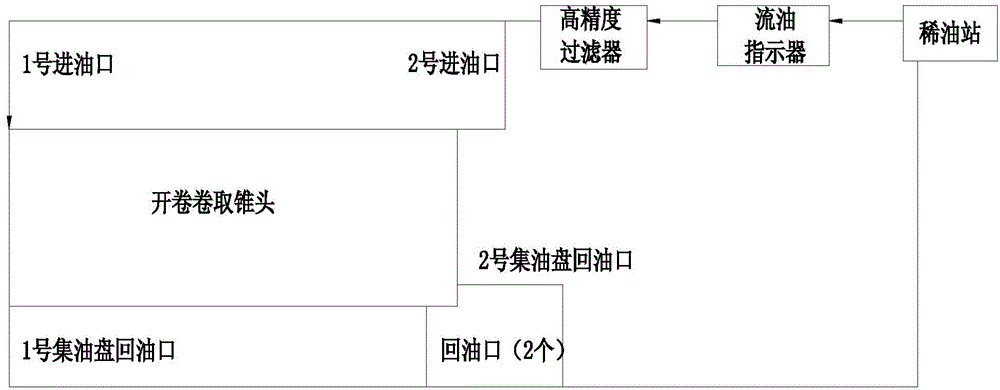

Thin oil returning structure of conical heads of uncoiling machine and coiling machine

InactiveCN104456042AIncrease oil returnImprove the efficiency of oil returnLubrication elementsMechanical engineeringOil intake

The invention discloses a thin oil returning structure of conical heads of an uncoiling machine and a coiling machine. The thin oil returning structure comprises a conical head base and a slide sleeve, wherein a rotary shaft is arranged in the slide sleeve; a bearing arranged between the rotary shaft and the slide sleeve is respectively arranged at each of the front and rear ends of each of the rotary shaft and the slide sleeve; a sealed lubricating cavity and an air hole are formed between the rotary shaft and the slide sleeve; a front end cover and a rear end cover are respectively arranged at the front and the rear ends of the slide sleeve; the left and right ends of the lubricating cavity are sealed and capped by virtue of the front end cover and the rear end cover; a first oil inlet is formed in the front end cover, and a second oil inlet is formed in the rear end cover; a first oil collecting plate is connected to the front end cover; an oil returning opening of the first oil collecting plate is connected to a thin oil station; a second oil collecting plate is connected to the rear end cover; an oil returning opening of the second oil collecting plate is also connected to the thin oil station. Through the adoption of the thin oil returning structure disclosed by the invention, the lubricating oil is intensively collected in the oil collecting plate while leaking from the sealing ring; the lubricating oil is collected to avoid polluting the spot environment, the oil returning amount is greased, and the oil returning efficiency is greatly improved.

Owner:镇江市宏业科技有限公司

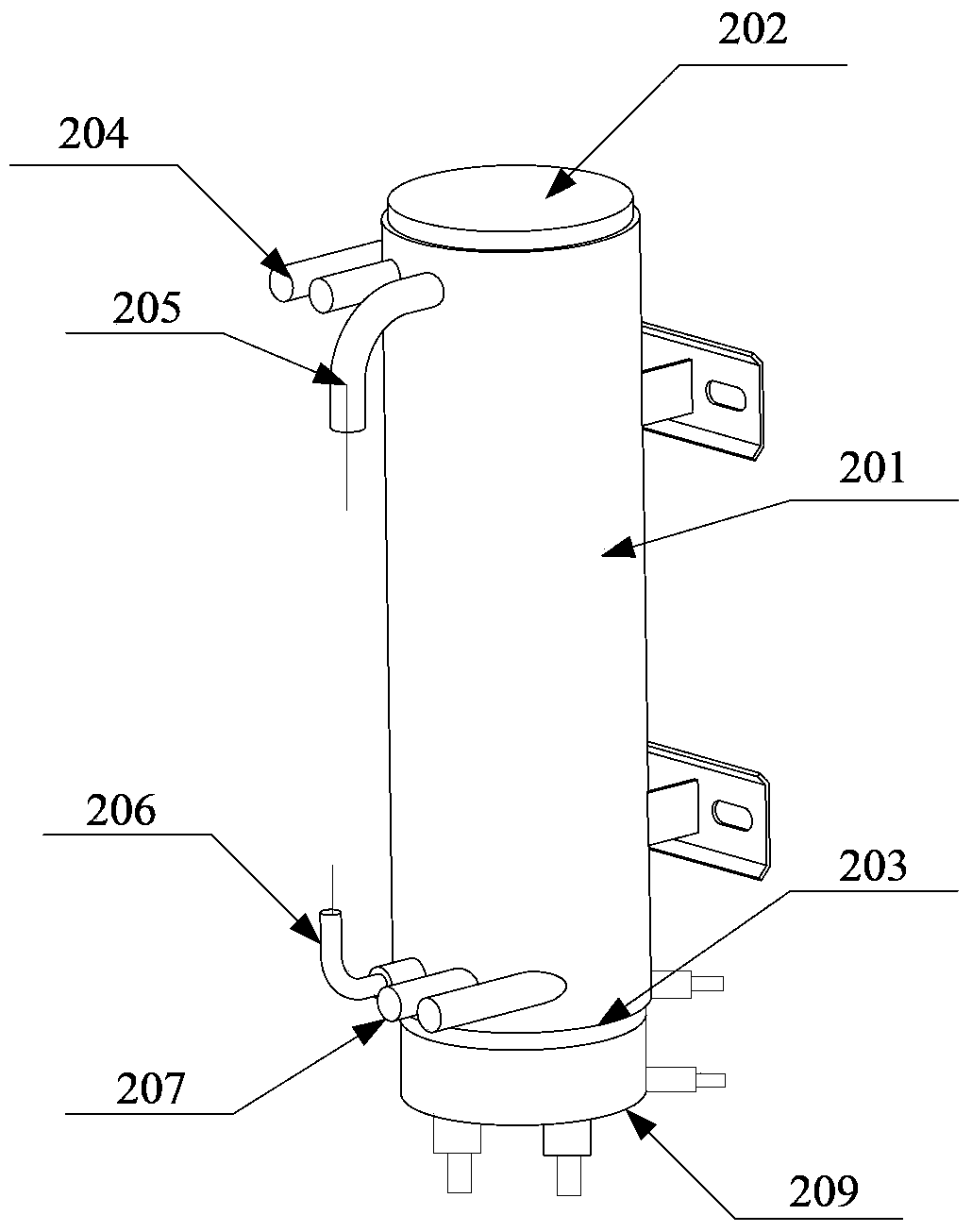

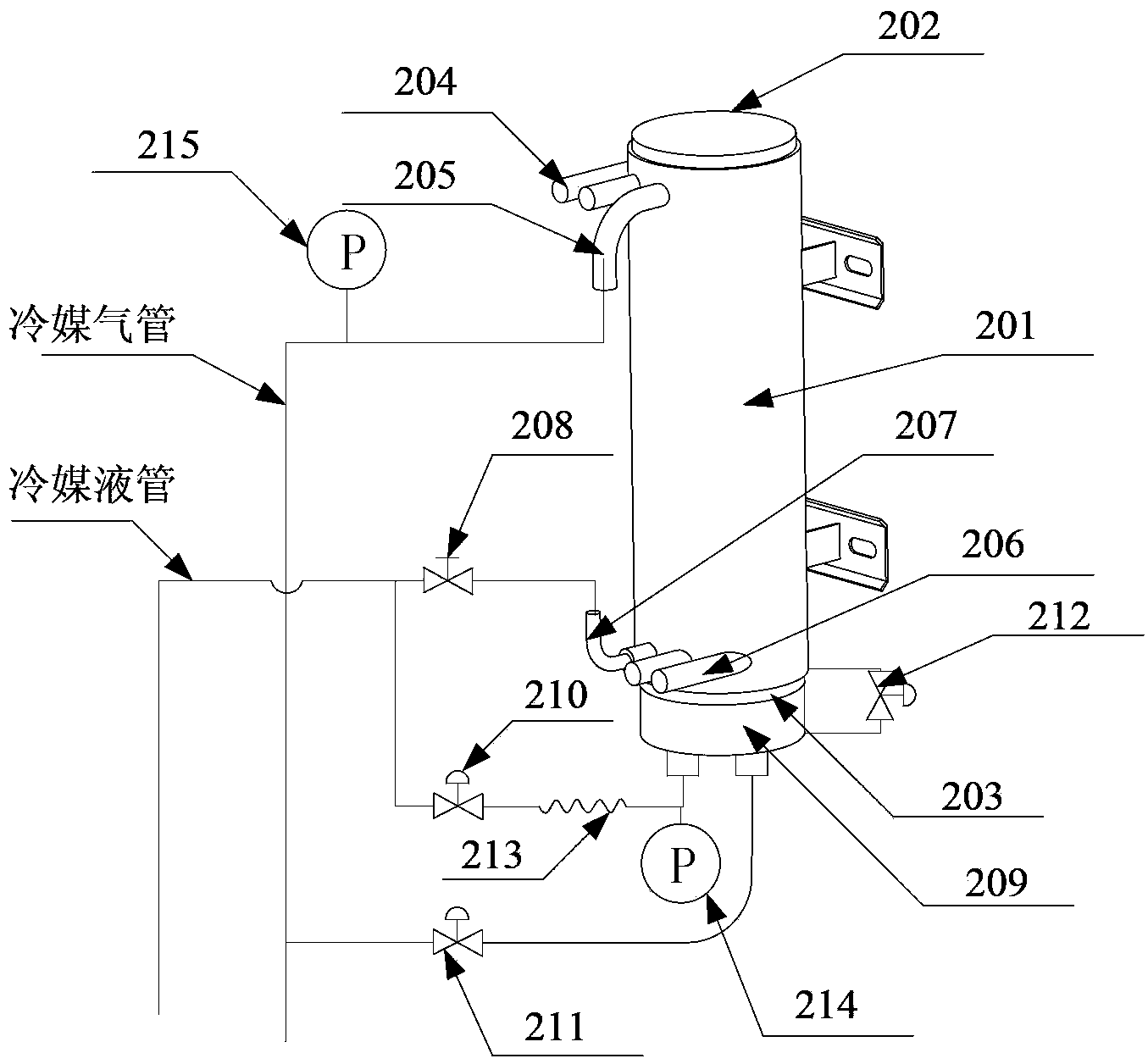

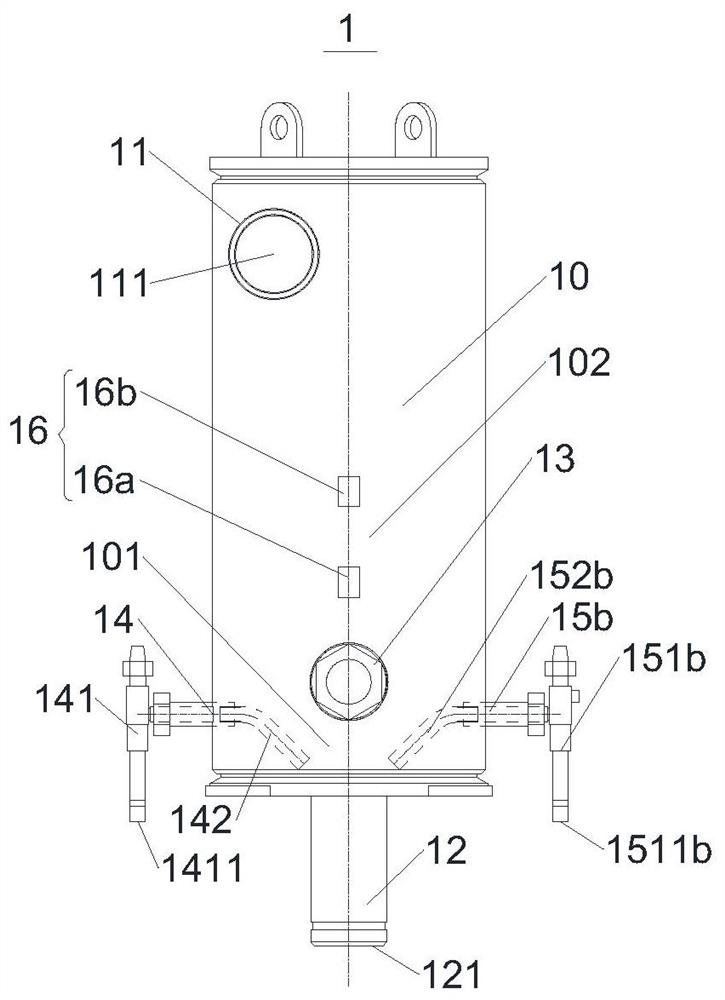

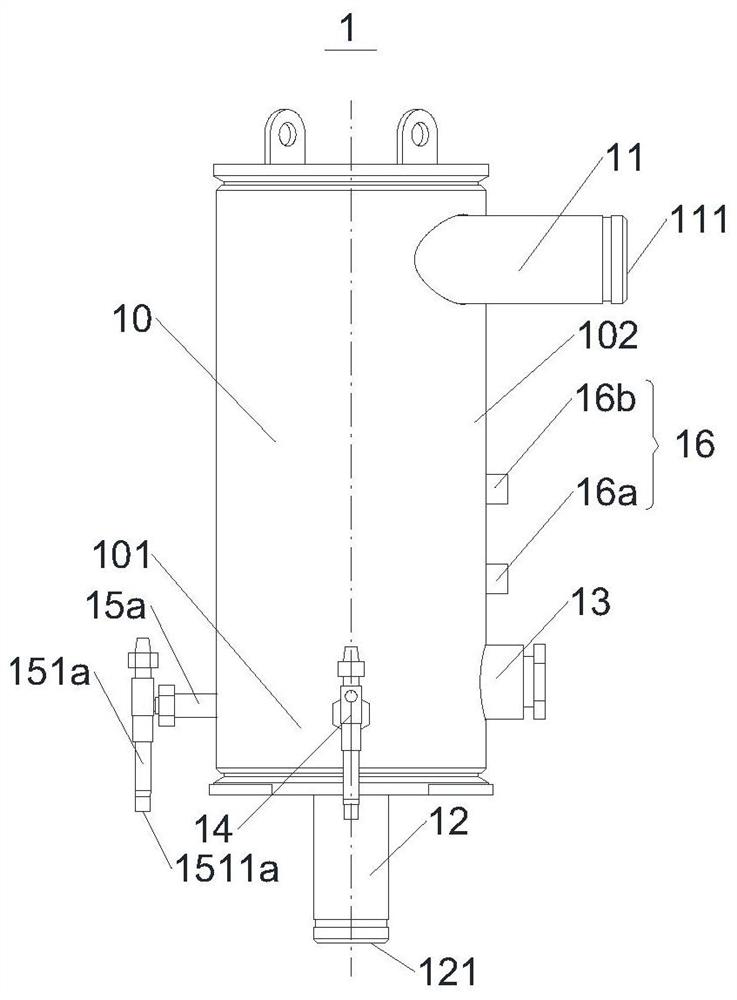

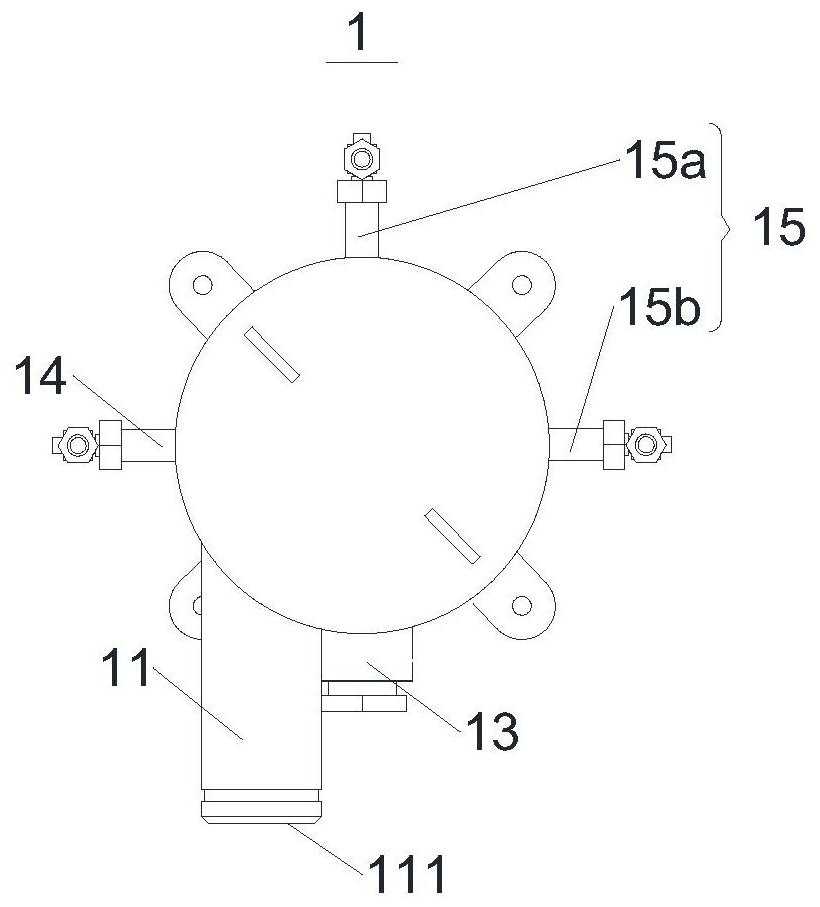

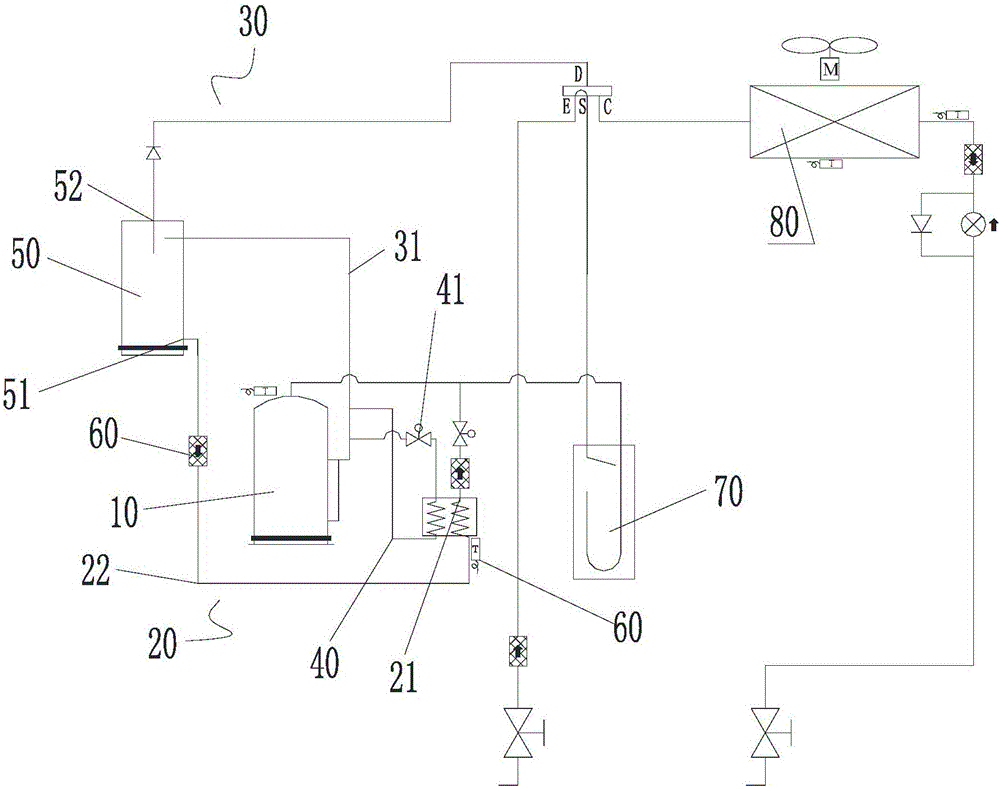

Oil separator, oil return system and refrigerating system

ActiveCN113465231AImprove stabilityImprove oil return efficiencyCompressorMechanical apparatusOil canThermodynamics

The invention relates to an oil separator, an oil return system and a refrigerating system. The oil separator comprises a cylinder, a basic oil return opening formed in the lower part of the cylinder, at least one enhanced oil return opening, and at least one oil level switch; each enhanced oil return opening and the basic oil return opening are spaced from each other on the cylinder; and each oil level switch is arranged on the side wall of the cylinder, each oil level switch corresponds to one enhanced oil return opening, and the corresponding oil level height in the cylinder is monitored, and each enhanced oil return opening is lower than any one of the at least one oil level switch in the height direction of the cylinder. According to the oil separator, oil can be returned in time, and the oil return efficiency is remarkably improved. The invention further discloses the oil return system and the refrigerating system comprising the oil separator.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +2

Air conditioner system, air conditioner system control method and air conditioner

ActiveCN105972868AImprove oil return efficiencyExtended service lifeCompressorRefrigeration safety arrangementProcess engineeringViscosity

The invention provides an air conditioner system, an air conditioner system control method and an air conditioner. The air conditioner system comprises a compressor, an oil return pipeline communicating with the oil return end of the compressor, a heating pipeline which is at least partially adjacent to the oil return pipeline, wherein when a coolant with preset temperature is introduced into the heating pipeline, the heating pipeline exchanges heat with the oil return pipeline, to increase the oil return temperature of the oil return pipeline. By the arrangement of the heating pipeline which exchanges heat with the oil return pipeline, the coolant in the air conditioner system is introduced into the heating pipeline, and the coolant entering the heating pipeline can supply heat to the oil return pipeline, so that the oil return temperature in the oil return pipeline can be increased; and therefore, the viscosity of oil in the oil return pipeline is reduced, the oil return efficiency of the compressor is improved, and the service life of the compressor is effectively prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

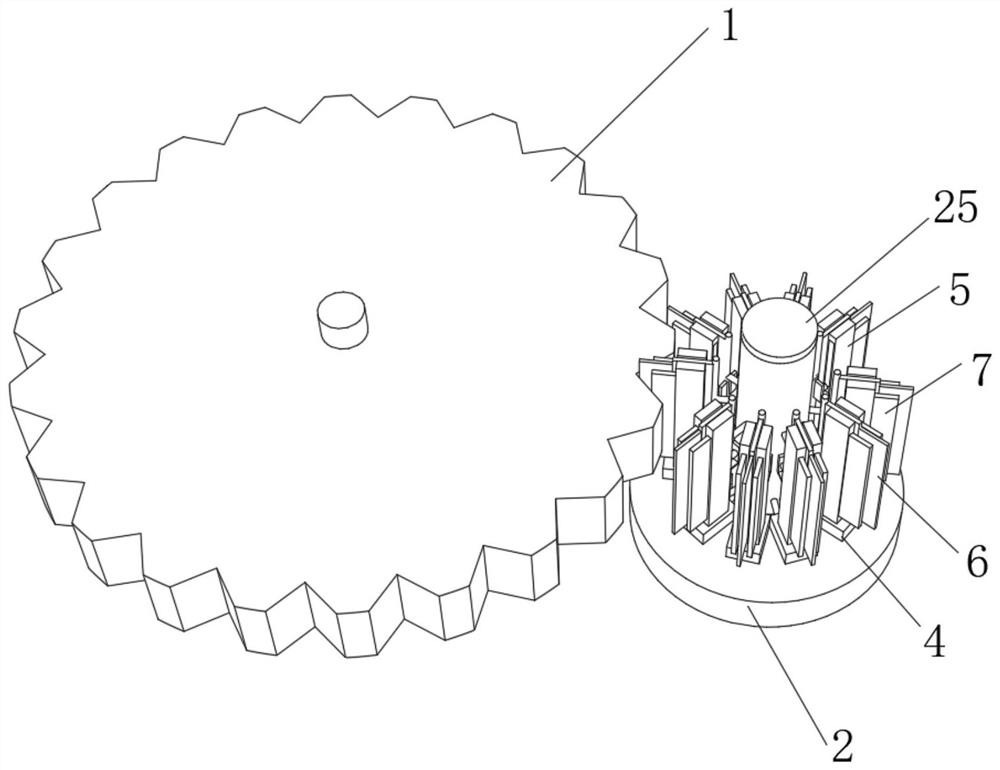

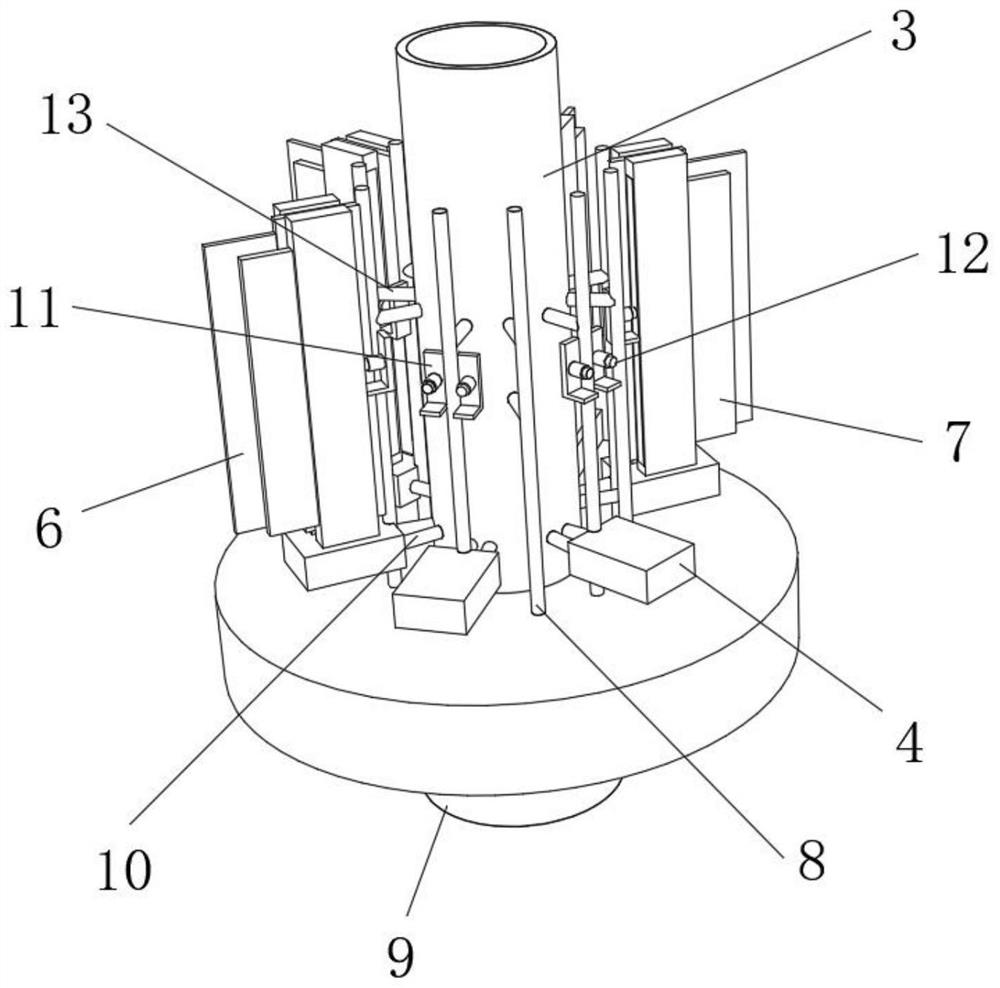

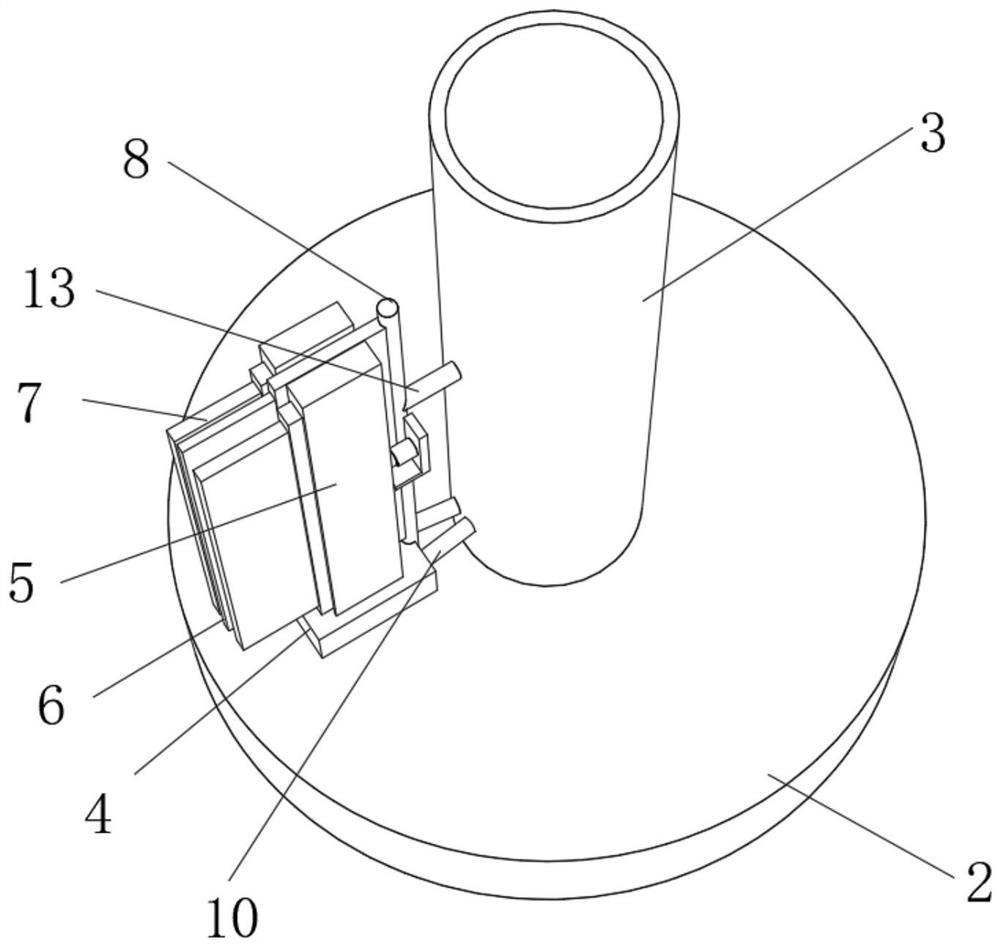

Lubricating grease coating device for electromechanical equipment installation

The invention belongs to the technical field of machinery, and particularly relates to a lubricating grease coating device for electromechanical equipment installation. Aiming at the problems that a lubricating grease coating device in the prior art is difficult to clean the gaps between the tooth blocks of the gear in a machine, and the tooth-block gaps of the gear is inconvenient to be uniformlyoiled in the later period, the following scheme is provided that the device comprises an oil return box rotationally connected to the upper end of a supporting turntable, an oil storage pipe is fixedly connected to the center of the upper end of the oil return box, a plurality of lubricating oil coating assemblies meshed with a gear are fixedly connected to the upper end of the oil return box, amud pump is connected to the inner side of the oil return box, a coarse slag filter screen is arranged on the inner side of the oil return box, the inner side of the oil storage pipe is connected withan oil pump, the input end of the oil pump is connected with an oil return pipe, and the lower end of the oil return pipe is connected with oil return nozzles. According to the lubricating grease coating device, stable cleaning of oil stains at the tooth-block gaps of the gear and stable oiling after cleaning can be achieved, the oiling difficulty coefficient of the gear surface is greatly reduced, and meanwhile, the coating quality of a lubricating oil is improved.

Owner:SUZHOU LAIJIN ELECTROMECHANICAL AUTOMATION CO LTD

Oil quick-returning-discharging circuit for oil cylinder of hydraulic machine

ActiveCN103557197AAvoid the problem of increased manufacturing cost of the oil discharge circuitAvoid size restrictionsServomotor componentsServomotorsFuel tankElectromagnetic valve

The invention relates to an oil return circuit for an oil cylinder, in particular to an oil quick-returning-discharging circuit for an oil cylinder of a hydraulic machine. The oil quick-returning-discharging circuit comprises the oil cylinder and a main reversing valve, wherein the oil cylinder is vertically arranged; the main reversing valve is provided with a first oil outlet, a second oil outlet, an oil inlet and an oil return opening; the first oil outlet of the main reversing valve is connected with the lower cavity of the oil cylinder through an oil pipe; the oil return opening of the main reversing valve is connected with an oil tank through an oil pipe. The oil quick-returning-discharging circuit is characterized in that the lower cavity of the oil cylinder is connected with the oil inlet of the main reversing valve through an oil pipe; the second oil outlet of the main reversing valve is connected with the oil tank through an oil pipe. The oil quick-returning-discharging circuit can achieve the oil quick-returning effect of the oil cylinder of the hydraulic machine under the condition that the diameters of the first oil outlet and the oil return opening of the main reversing valve are not enlarged and no special oil return electromagnetic valve is additionally arranged, so that the manufacturing cost is lowered.

Owner:无锡蓝力智能装备有限公司

Floating oil recovery device

ActiveCN104164859AImprove oil return efficiencyWater cleaningGeneral water supply conservationControl systemFuel tank

The invention relates to a floating oil recovery device. The floating oil recovery device comprises an oil suction unit, a pump and an oil-water separator. The oil suction unit comprises a floating oil tank, an inclined baffle, a bottom plate, an oil suction disk, an oil suction pipe and a control system. A partition plate is arranged in the floating oil tank. The top and the sides of the partition plate are all connected with the tank body of the floating oil tank, a channel opening for oil to enter is arranged between the bottom end of the partition plate and the bottom of the tank body of the floating oil tank, the channel opening is lower than the top end of the inclined baffle, and the top end of the inclined baffle is lower than a suction opening of the oil suction disk. A vacuum chamber and a vacuum pump are arranged on the upper portion of the floating oil tank, and the vacuum chamber and the inclined baffle are arranged on the two sides of the partition plate respectively, and communicated with the floating tank. Due to the structure, under the vacuum action, the return oil liquid level in a cavity where the oil suction disk is located is higher than the liquid level on one side of the inclined baffle, the height difference between the return oil liquid level and the suction opening of the oil suction disk can be controlled through the vacuum degree so as to be kept within a certain range, and thus the suction opening of the oil suction disk is kept immersed below the return oil liquid level, air is effectively prevented from being sucked in, and the oil return efficiency is prevented from being reduced.

Owner:ZHEJIANG OCEAN UNIV

A floating oil recovery device

ActiveCN104164859BImprove oil return efficiencyWater cleaningGeneral water supply conservationControl systemFuel tank

The invention relates to a floating oil recovery device. The floating oil recovery device comprises an oil suction unit, a pump and an oil-water separator. The oil suction unit comprises a floating oil tank, an inclined baffle, a bottom plate, an oil suction disk, an oil suction pipe and a control system. A partition plate is arranged in the floating oil tank. The top and the sides of the partition plate are all connected with the tank body of the floating oil tank, a channel opening for oil to enter is arranged between the bottom end of the partition plate and the bottom of the tank body of the floating oil tank, the channel opening is lower than the top end of the inclined baffle, and the top end of the inclined baffle is lower than a suction opening of the oil suction disk. A vacuum chamber and a vacuum pump are arranged on the upper portion of the floating oil tank, and the vacuum chamber and the inclined baffle are arranged on the two sides of the partition plate respectively, and communicated with the floating tank. Due to the structure, under the vacuum action, the return oil liquid level in a cavity where the oil suction disk is located is higher than the liquid level on one side of the inclined baffle, the height difference between the return oil liquid level and the suction opening of the oil suction disk can be controlled through the vacuum degree so as to be kept within a certain range, and thus the suction opening of the oil suction disk is kept immersed below the return oil liquid level, air is effectively prevented from being sucked in, and the oil return efficiency is prevented from being reduced.

Owner:ZHEJIANG OCEAN UNIV

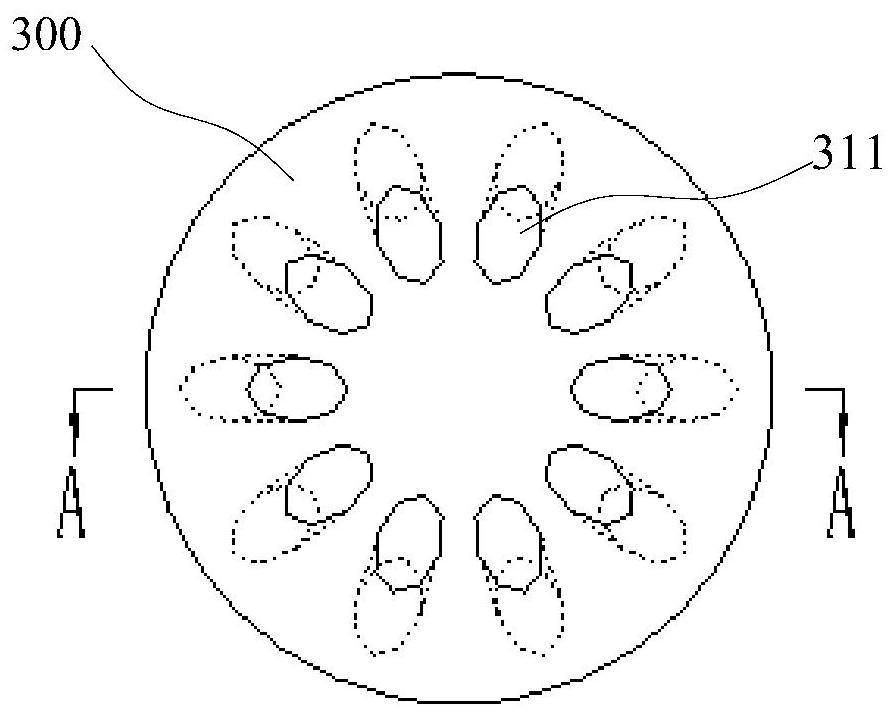

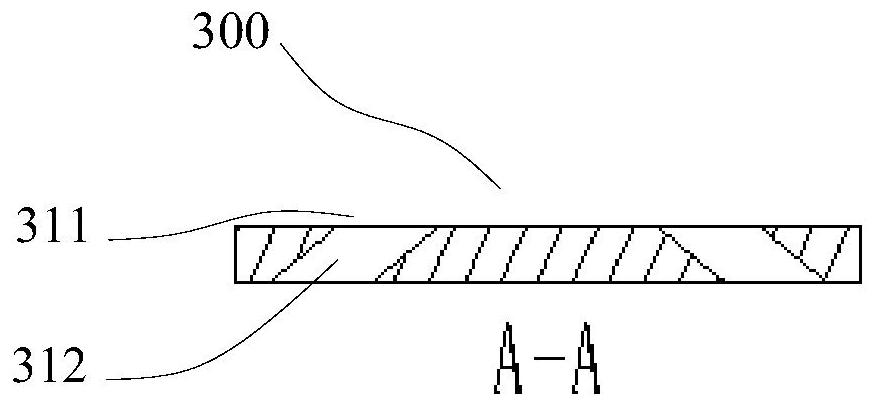

Evaporator, injection return flow system thereof and air conditioning unit

PendingCN109269157AGuaranteed liquid volumeImprove oil return efficiencyEvaporators/condensersEvaporatorEngineering

The invention relates to an evaporator, an injection return flow system thereof and an air conditioning unit. A high liquid taking port and a low liquid taking port are arranged on the side wall of the evaporator, an opening-closing component for opening and closing the high liquid taking port and the low liquid taking port is arranged in the evaporator, and a control component for controlling opening-closing state of the opening-closing component to the high liquid taking port and the low liquid taking port is arranged in the evaporator. The opening-closing component is arranged to open and close the high liquid taking port and the low liquid taking port, and only one of the high liquid taking port and the low liquid taking port is controlled to be communicated with the outside constantlythrough the control component, so that one liquid taking port can be controlled and selected to be communicated with the outside through the control component; the evaporator can be ensured to have high oil return efficiency at different liquid levels.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

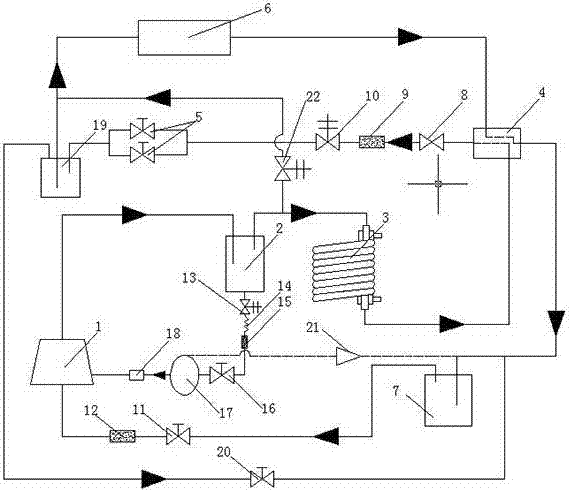

Automatic oil return device of carbon dioxide cascade refrigeration system

InactiveCN106766386AMinimal impact on normal operationIncrease contentCompressorGas cycle refrigeration machinesShell and tube heat exchangerEngineering

The invention discloses an automatic oil return device of a carbon dioxide cascade refrigeration system. The automatic oil return device comprises a shell-and-tube heat exchanger, adjusting valves, electromagnetic valves, a pressure-differential adjusting valve connected with the top of the shell side of the shell-and-tube heat exchanger, a liquid level meter connected with the shell side of the shell-and-tube heat exchanger, and two liquid level switches, wherein one adjusting valve and one electromagnetic valve are connected with the middle part of the shell side of the shell-and-tube heat exchanger; and the other adjusting valve and the other electromagnetic valve are connected with the bottom of the shell side of the shell-and-tube heat exchanger. The whole oil return device comprises 5 ports connected with external devices, namely port 1 connected with a condenser or a liquid reservoir, port 2 connected with an expansion valve, port 3 connected with a carbon dioxide pump outlet pipeline, port 4 connected with a circulatory barrel, and port 5 connected with an air suction port of a compressor. Through the adoption of the automatic oil return device disclosed by the invention, during the operation of the refrigeration system, refrigerant oil dissolved in carbon dioxide in the low-pressure circulatory barrel can be automatically extracted and returned to the compressor, so that the heat exchange efficiency of refrigeration equipment is improved; and the refrigerating capacity of the refrigeration system is not lost during operation, and the operation of the compressor is not influenced, so that the practicability is high.

Owner:DALIAN REFRIGERATOR

Self-adaptive suspension centering device for die assembly

ActiveCN110370016AImprove oil return efficiencyImplementation driveMetal working apparatusSelf adaptiveMechanical engineering

The invention relates to the technical field of die assembly and discloses a self-adaptive suspension centering device for die assembly. The device comprises a bearing base, a bearing plate and a plunger, wherein a hydraulic cavity is arranged between the bearing base and the bearing plate, a plunger cavity is arranged on the bearing plate, a through hole connecting the plunger cavity and the hydraulic cavity is arranged in the bearing plate, the plunger is in sliding fit with the plunger cavity, a limiting structure is arranged on the bearing plate and located at the upper end of the plungercavity, and a spring is arranged between the lower end of the plunger and the plunger cavity; and the bearing plate comprises a support plate and an extension part, the support plate is in floating connection with the bearing base, an oil return cavity and an adjustable sealing structure are further arranged between the bearing base and the bearing plate, and the oil return cavity communicates with the hydraulic cavity through a pipeline. The self-adaptive suspension centering device for die assembly, provided by the invention, solves the problem of difficult centering in a die assembly process. By adopting the structure of the device, the positions of pin holes can be automatically located through the fine adjustment of the position of a lower die, assembly is easily finished, the assembly efficiency of the die is increased, and the assembly precision is improved.

Owner:绵阳飞腾精密机械科技有限公司

Oil return control method, device, system and air conditioner for temperature regulating equipment

ActiveCN110285544BThrottling does not occurImprove oil return efficiencyCompressorMechanical apparatusThermodynamicsTemperature conditioning

The invention relates to a temperature adjusting equipment oil return control method, device and system and an air conditioner. Air temperature information within the future preset time period is obtained; when it is determined that the advance oil return condition is met according to the air temperature information within the future preset time period and the preset oil return frequency reduction critical temperature, the oil return duration is determined according to the air temperature information within the future preset time period and a preset compressor oil return duration model; and the oil return timing is determined according to the oil return duration and the air temperature information within the future preset time period, and according to the oil return timing, a compressor of temperature adjusting equipment is controlled to start oil return at the oil return timing. When it is judged that oil return needs to be conducted in advance by combining the air temperature information within the future preset time period with the preset oil return frequency reduction critical temperature, the advance oil return timing is determined according to the air temperature information within the future preset time period and the preset compressor oil return duration model, thus, the compressor completes oil return before the air temperature is raised to the preset oil return frequency reduction critical temperature, it is ensured that the compressor can conduct oil return at the highest frequency, and protective frequency reduction does not occur, and the oil return efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Oil return device and air conditioning unit

The invention discloses an oil return device and an air-conditioning unit which belongs to the technical field of air conditioning and is designed to solve the problem of low oil return efficiency of the existing device. The invention relates to an oil return device, comprising an oil return assembly provided with a return port, a float, a heavy hammer and a return pipe, among which the oil return assembly is connected with the float, the upper end of the heavy hammer is connected with the float or the oil return assembly, the lower end is connected to the upper end of the oil return pipe, the oil return port communicates with the oil return pipe, and the oil return pipe can adjust its length in the vertical direction at least according to its force in the vertical direction. In that oil return device and the air-condition unit of the invention, the buoyancy and gravity balance principle are used, such that the oil return port can be accurately position in the vertical direction of the liquid surface of the oil-rich layer with the lowest height, so that the oil return is reliable, the oil return efficiency is improve, and the oil-free operation of the compressor is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

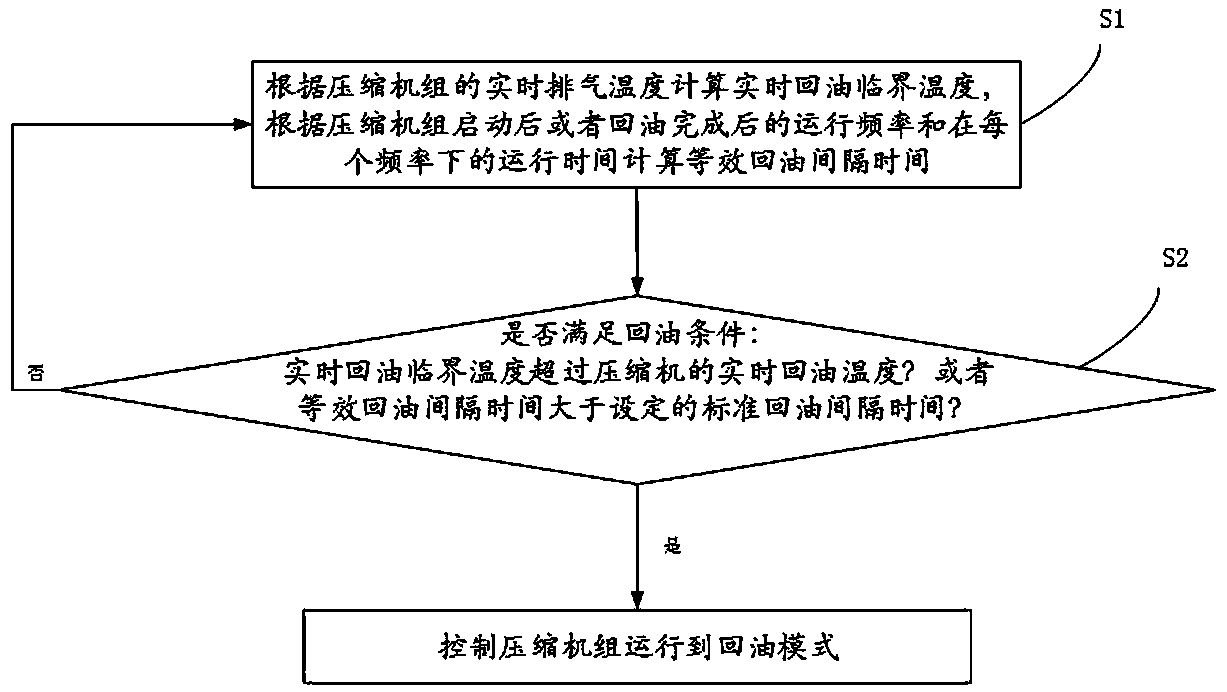

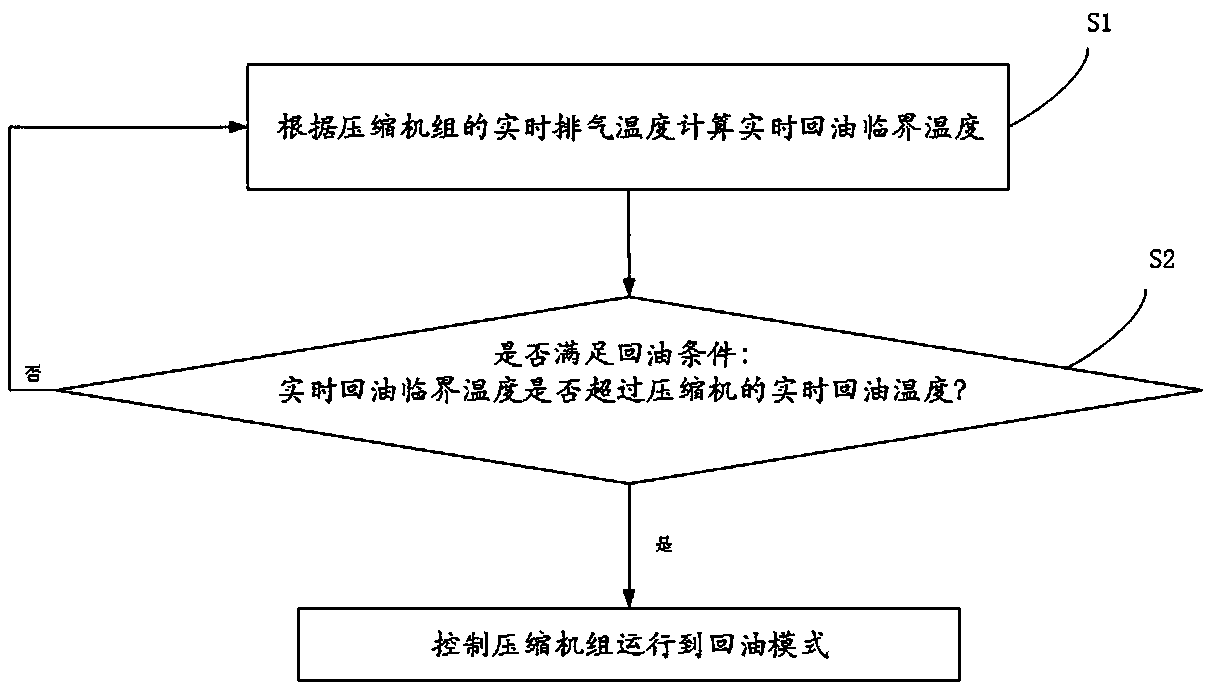

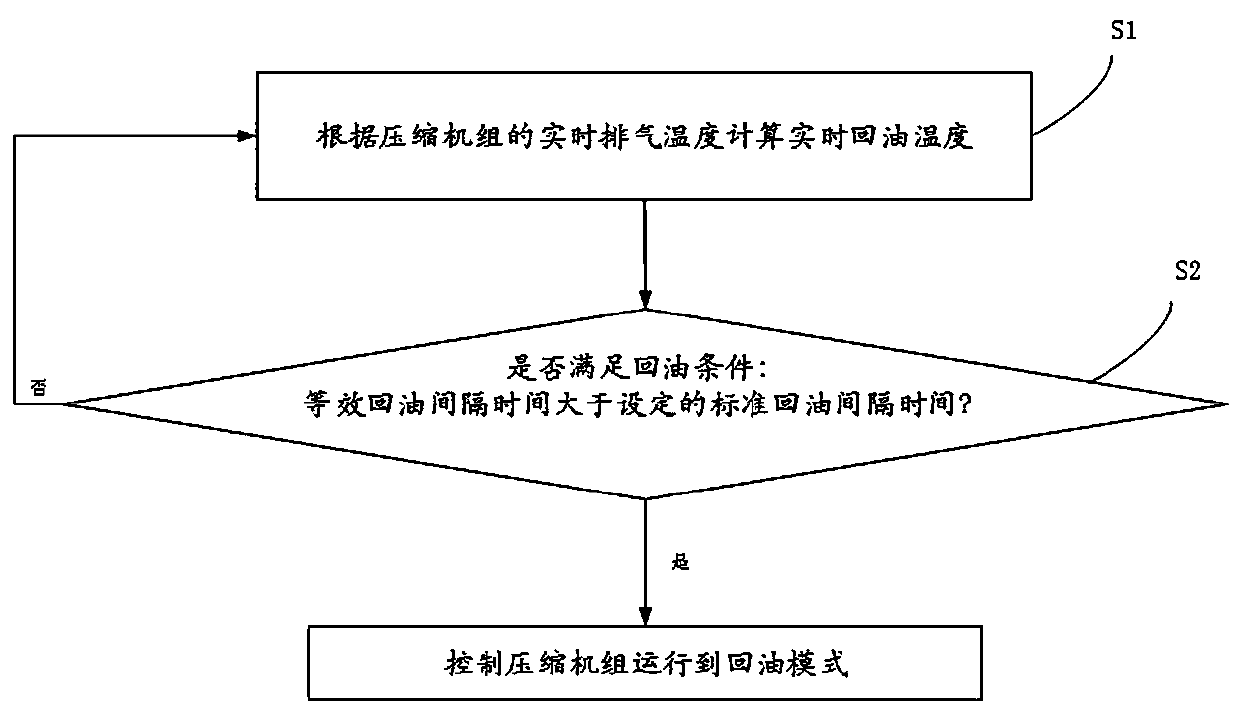

Oil return control method for an air-conditioning compressor unit

ActiveCN109114844BImprove running stabilityImprove oil return efficiencyCompressorRefrigeration safety arrangementThermodynamicsControl theory

Owner:GREE ELECTRIC APPLIANCES INC

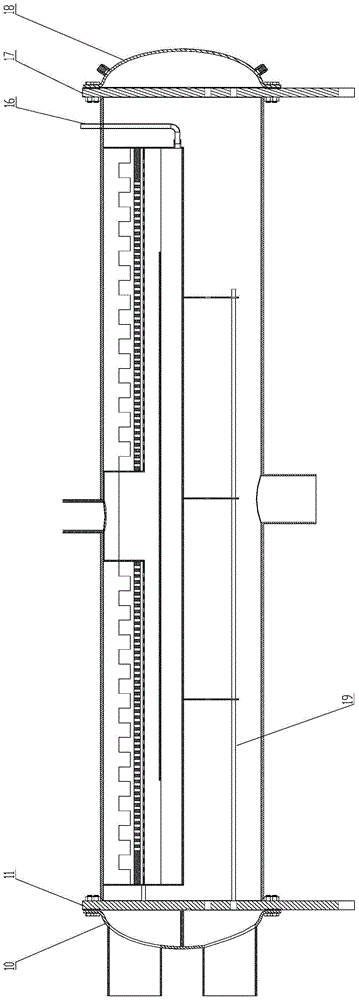

A kind of heat exchange equipment and its oil return type condenser

ActiveCN104833140BImprove separation efficiencySimple structureEvaporators/condensersOil separationEqualization

The invention discloses an oil return type condenser. An oil separator is arranged in the condenser, and the built-in oil separator has the advantages of being high in oil separation efficiency, simple in structure, simple in pipeline and the like. The built-in oil separator carries out primary separation through a knocking baffle, then carries out secondary separation through a flow equalization board, and finally caries out tertiary separation through a filter screen. The oil separation efficiency is improved through the arrangement, coolants can evenly enter the condenser and make contact with a condenser pipe more evenly through the design of an outlet of the built-in oil separator, and the heat exchanging efficiency of the condenser is improved. The invention further discloses a heat exchanging device with the oil return type condenser.

Owner:GREE ELECTRIC APPLIANCES INC

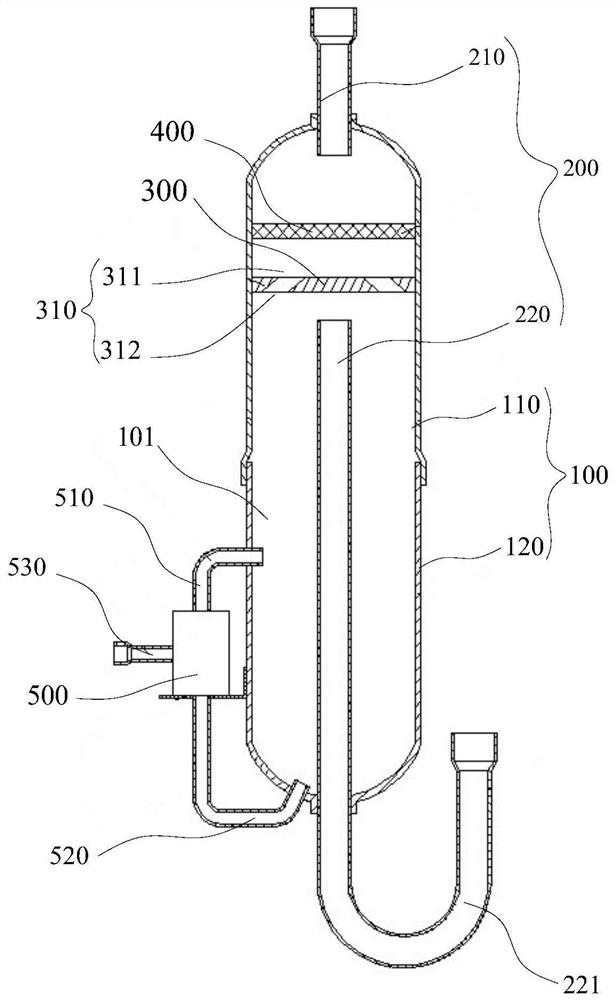

Oil separator, compressor, electric appliance and control method of oil separator

PendingCN113465239AEasy to separateAvoid enteringRefrigeration safety arrangementThermodynamicsOil separation

The invention relates to an oil separator, a heat exchange device, an electric appliance and a control method of the oil separator. The oil separator comprises a shell, an air pipe and a flow guide part. A separation cavity is formed in the shell. The air pipe comprises an air inlet pipe and an air outlet pipe, the inner end of the air inlet pipe communicates with the separation cavity, the outer end of the air inlet pipe communicates with the compressor, the inner end of the air outlet pipe extends into the separation cavity, and an oil storage space is formed in the lower part of the separation cavity. The flow guide part is connected into the shell to separate the separation cavity, the flow guide part is located between the inner end of the air inlet pipe and the inner end of the air outlet pipe, the flow guide part is provided with flow channels, each flow channel comprises a first opening formed in the first surface of the flow guide part and a second opening formed in the second surface of the flow guide part, the distance between the second openings and the inner wall of the shell is smaller than that between the first openings and the inner wall of the shell, and the second openings deviate from the inner end of the air outlet pipe. The flow guide part has the flow guide effect, the proportion of oil entering the air outlet pipe can be greatly reduced, after the oil is discharged from the second opening and condensed, most of the oil is gathered in the oil storage space, the oil-gas separation efficiency can be improved, and the oil shortage problem of the compressor is solved.

Owner:GREE ELECTRIC APPLIANCES INC

The hydraulic cylinder returns to the quick oil discharge circuit

ActiveCN103557197BAvoid the problem of increased manufacturing cost of the oil discharge circuitAvoid size restrictionsServomotor componentsServomotorsHydraulic cylinderFuel tank

The invention relates to an oil return circuit for an oil cylinder, in particular to an oil quick-returning-discharging circuit for an oil cylinder of a hydraulic machine. The oil quick-returning-discharging circuit comprises the oil cylinder and a main reversing valve, wherein the oil cylinder is vertically arranged; the main reversing valve is provided with a first oil outlet, a second oil outlet, an oil inlet and an oil return opening; the first oil outlet of the main reversing valve is connected with the lower cavity of the oil cylinder through an oil pipe; the oil return opening of the main reversing valve is connected with an oil tank through an oil pipe. The oil quick-returning-discharging circuit is characterized in that the lower cavity of the oil cylinder is connected with the oil inlet of the main reversing valve through an oil pipe; the second oil outlet of the main reversing valve is connected with the oil tank through an oil pipe. The oil quick-returning-discharging circuit can achieve the oil quick-returning effect of the oil cylinder of the hydraulic machine under the condition that the diameters of the first oil outlet and the oil return opening of the main reversing valve are not enlarged and no special oil return electromagnetic valve is additionally arranged, so that the manufacturing cost is lowered.

Owner:无锡蓝力智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com