Lubricating grease coating device for electromechanical equipment installation

A technology of lubricating grease and coating device, applied in the direction of mechanical equipment, engine lubrication, lubricating parts, etc., can solve the problems of uniform oiling and cleaning of the tooth block gap of the inconvenient gear, so as to improve the oiling quality and improve the return rate. The effect of improving oil quality and improving oil return efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

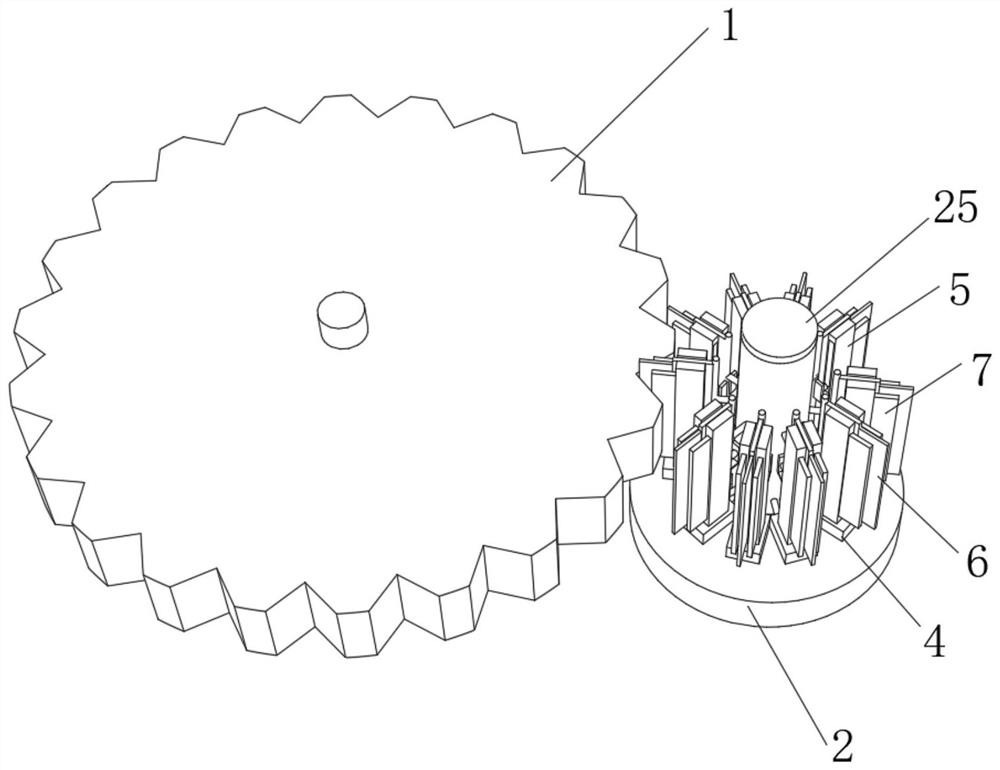

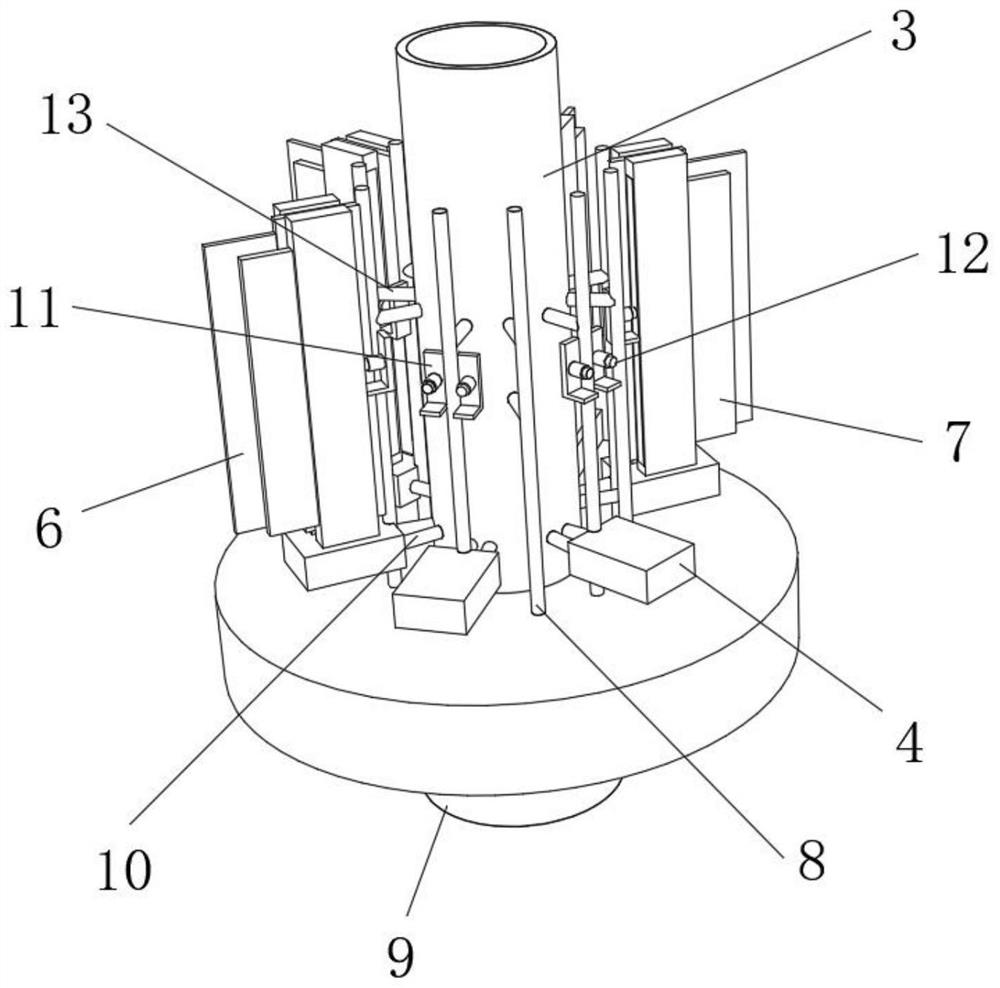

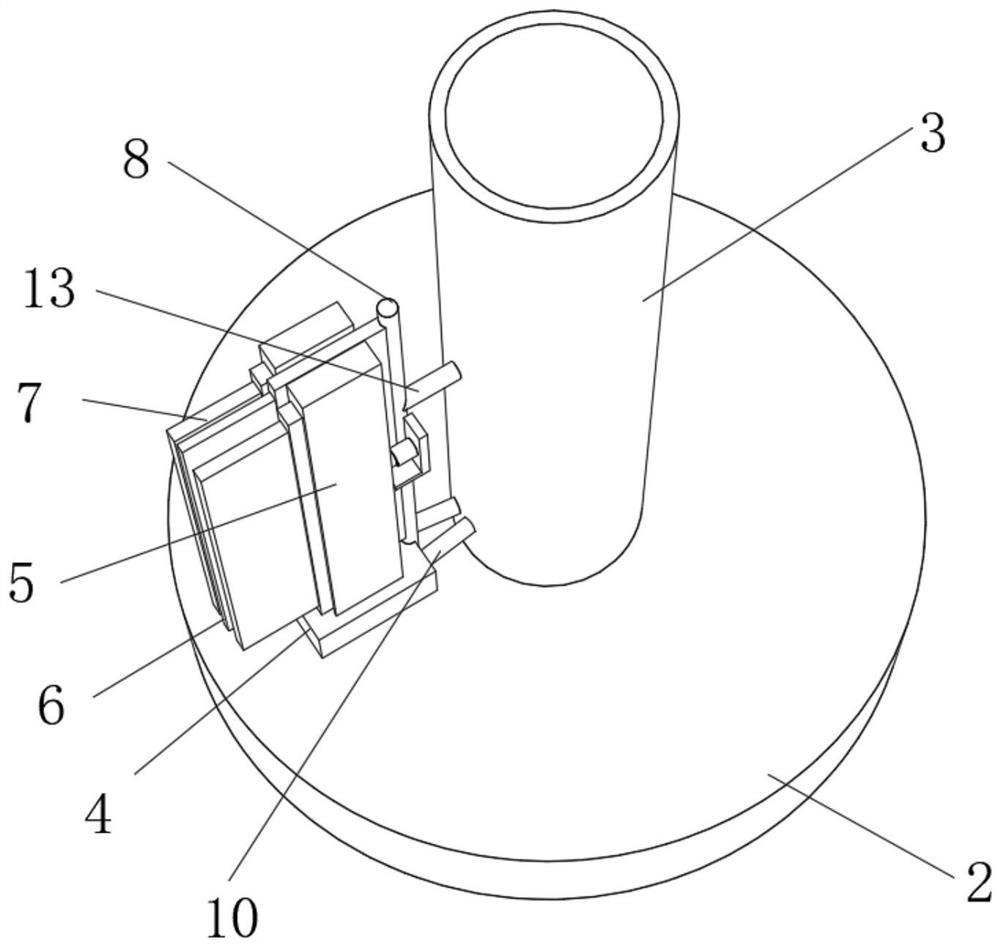

[0029] refer to Figure 1-5 , a lubricating grease coating device for installing electromechanical equipment, comprising an oil return box 2 rotatably connected to the upper end of a support turntable 9, an oil storage pipe 3 is fixedly connected to the center of the upper end of the oil return box 2, and the upper end of the oil return box 2 is fixedly connected to multiple A lubricating oil removal assembly meshed with the gear 1, and a support column 13 is fixedly connected between a plurality of lubricating oil removal assemblies and the outer wall of the oil storage pipe 3, and a mud pump 14 is connected to the inner side of the oil return box 2, and the mud pump 14 The input pipe 15 is connected with the lubricating oil removal assembly, the output pipe 23 of the mud pump 14 is connected with the inner side of the oil return box 2, and the inner side of the oil return box 2 is provided with a coarse slag filter screen 17, and the coarse slag filter screen 17 is connected ...

Embodiment 2

[0039] refer to Figure 1-4 , a lubricating grease coating device for the installation of electromechanical equipment. Compared with Embodiment 1, the oil storage pipe 3 in this embodiment is a transparent tube, which is convenient for the operator to observe the amount of lubricating oil stored in the oil storage pipe 3 from the outside. The oil storage pipe 3 The upper end is provided with an oil filling port, and the oil filling port is plugged with a sealing plug 25. Opening the sealing plug 25, additional new lubricating oil can be added to the oil storage pipe 3 to maintain stable oiling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com