Device and method for controlling oil-containing uniformity and stability of tows during acrylic fiber oiling

A technology of stability and tow, which is applied in the field of spinning, can solve the problems of not being suitable for other substances, and the deviation of the concentration of the mother liquid of the oil agent, etc., and achieve the effect of stable oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

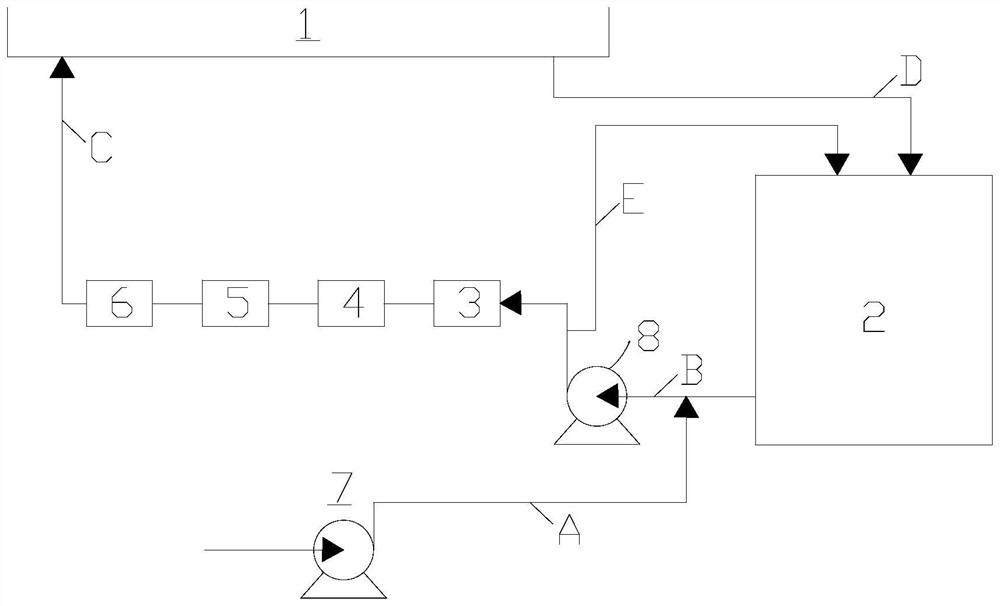

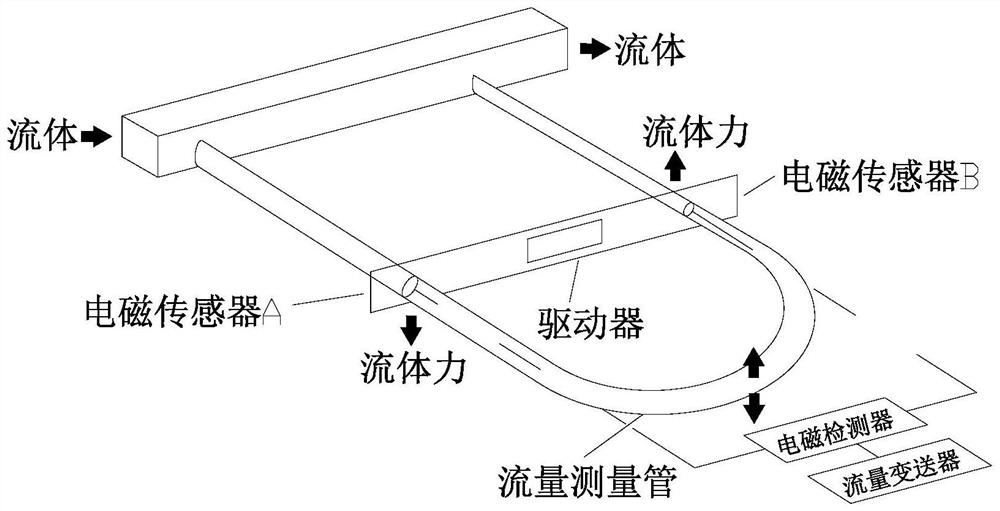

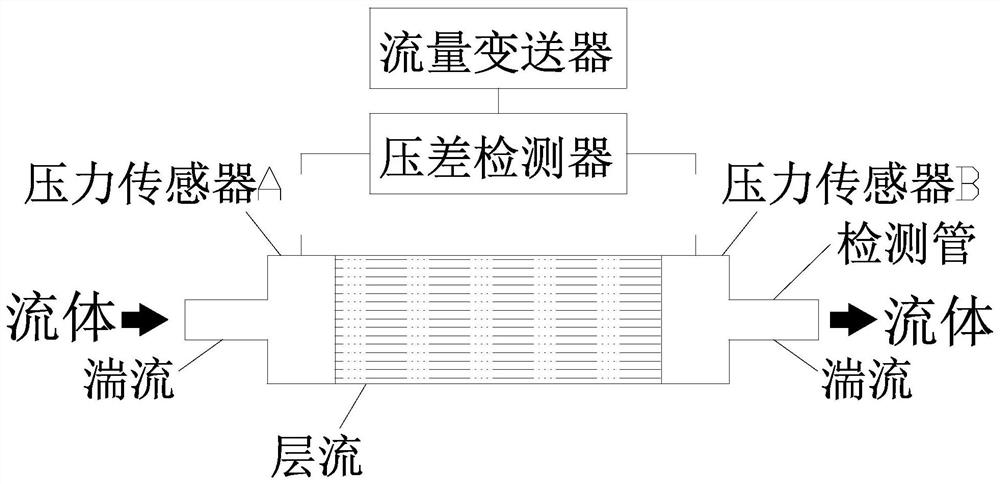

[0045] A device for controlling the uniformity and stability of the tow with oil when the acrylic fiber is oiled, such as figure 1 As shown, it includes thick oil agent replenishment line A, oil agent circulation line B, oil agent mother liquor conveying line C, conditioning and tempering oil tank 1, thin oil agent recovery line D, and conditioning and tempering tank 2 connected in sequence according to the flow direction; The oil agent circulation line is connected to the outlet of the conditioning tank, and the oil agent mother liquor return line E flowing to the tempering tank is provided on the oil agent mother liquor delivery line; the oil agent mother liquor delivery line is provided with oil filter according to the flow direction. device 3, oil heater 4, Coriolis mass flow controller 5 and differential pressure mass flow controller 6.

[0046] Wherein, the connection point between the oil agent mother liquor return line and the oil agent mother liquor delivery line is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com