Gas conveying equipment for metallurgical machinery

A technology for conveying equipment and gas, which is applied in mechanical equipment, gas/liquid distribution and storage, pipes/pipe joints/pipe fittings, etc. It can solve problems such as repairing worker injuries, blockage of gas conveying pipes, and difficulty in cleaning, to prevent leakage. Air, improve sealing, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

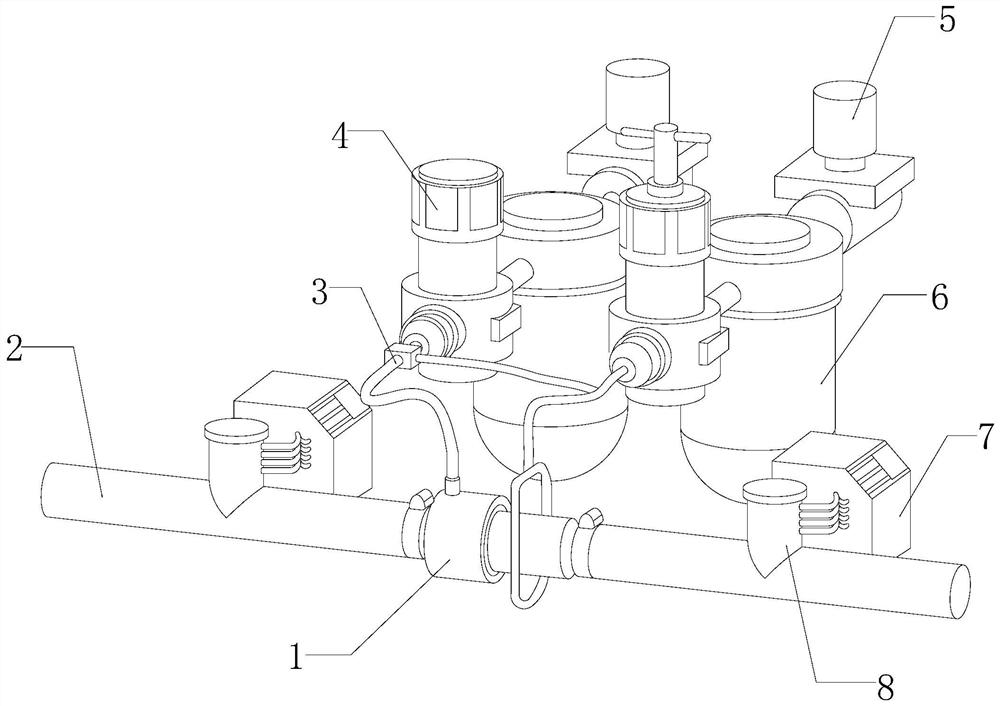

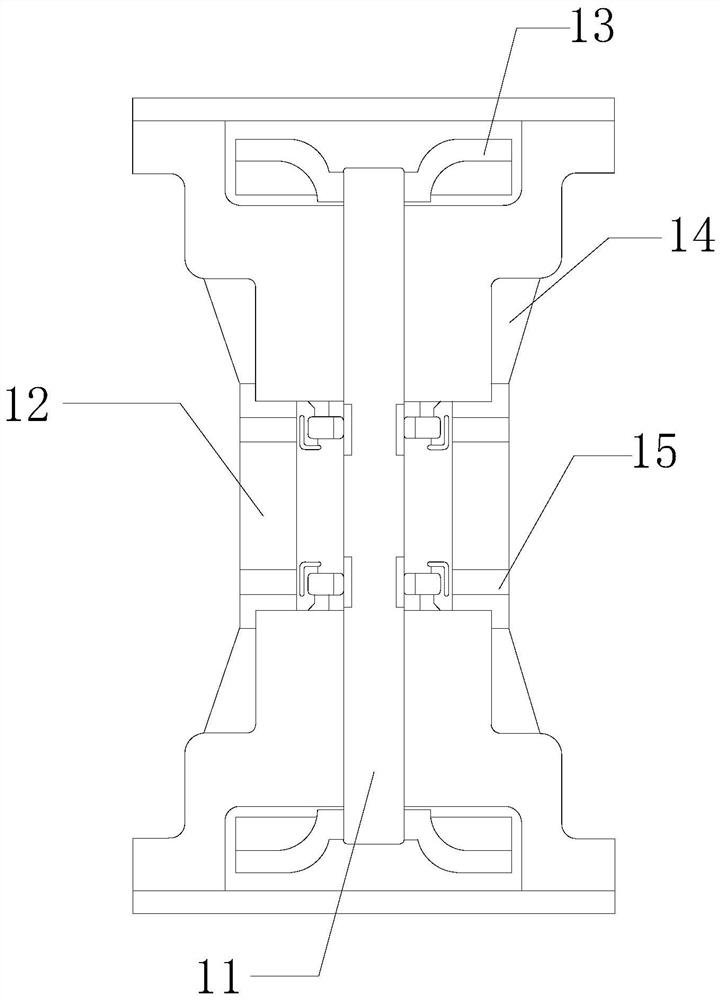

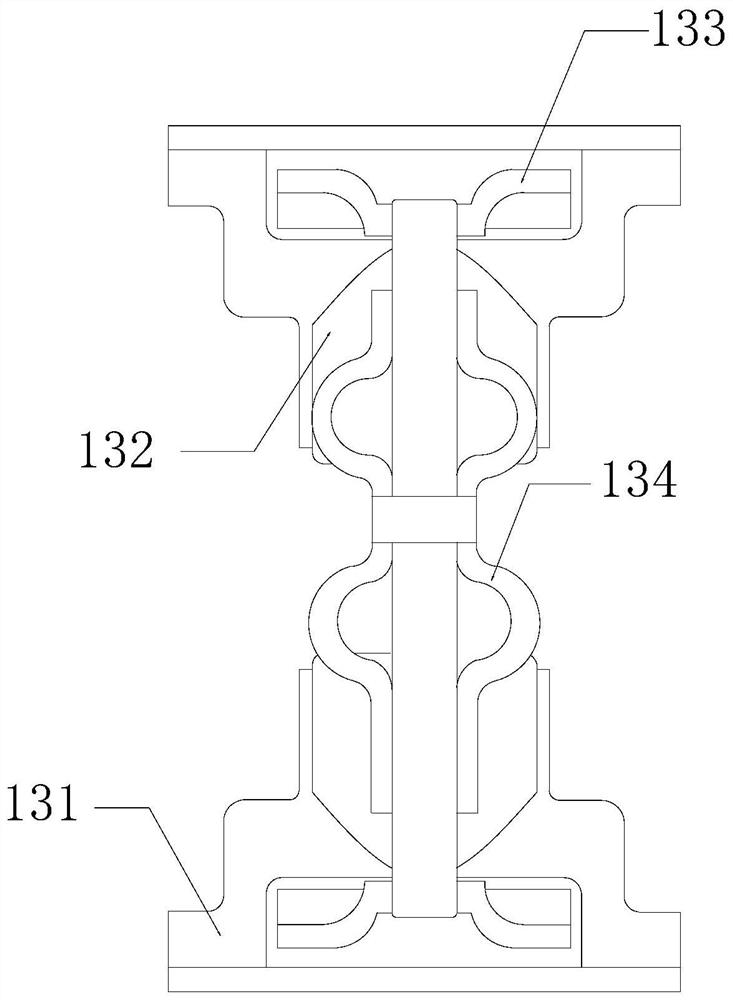

[0035] see figure 1, the present invention provides a technical solution: a gas conveying equipment for metallurgical machinery, its structure includes a processing device 1, a conveying pipe 2, a gas conveying pipe 3, an air flow chamber 4, a gas regulator 5, a gas storage chamber 6, and an outlet interface 7. Exhaust pipe 8, the processing device 1 is fitted in parallel on the conveying pipe 2, the two sides of the top of the conveying pipe 2 are provided with an exhaust pipe 8, and the exhaust pipe 8 is connected through the conveying pipe 2, the The exhaust pipe 8 communicates with the conveying pipe 2, the exhaust pipe 8 is connected with the outlet interface 7 as a whole, the outlet interface 7 is connected with the conveying pipe 2 through the exhaust pipe 8, and the outlet interface 7 is installed on On both sides of the conveying pipe 2, the top of the conveying pipe 2 is connected to the air conveying pipe 3, one end of the air conveying pipe 3 is connected inside t...

Embodiment 2

[0047] see figure 1 , the present invention provides a technical solution: a gas conveying equipment for metallurgical machinery, its structure includes a processing device 1, a conveying pipe 2, a gas conveying pipe 3, an air flow chamber 4, a gas regulator 5, a gas storage chamber 6, and an outlet interface 7. Exhaust pipe 8, the processing device 1 is fitted in parallel on the conveying pipe 2, the two sides of the top of the conveying pipe 2 are provided with an exhaust pipe 8, and the exhaust pipe 8 is connected through the conveying pipe 2, the The exhaust pipe 8 communicates with the conveying pipe 2, the exhaust pipe 8 is connected with the outlet interface 7 as a whole, the outlet interface 7 is connected with the conveying pipe 2 through the exhaust pipe 8, and the outlet interface 7 is installed on On both sides of the conveying pipe 2, the top of the conveying pipe 2 is connected to the air conveying pipe 3, one end of the air conveying pipe 3 is connected inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com