Self-adaptive suspension centering device for die assembly

A centering device and self-adaptive technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as difficult centering of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

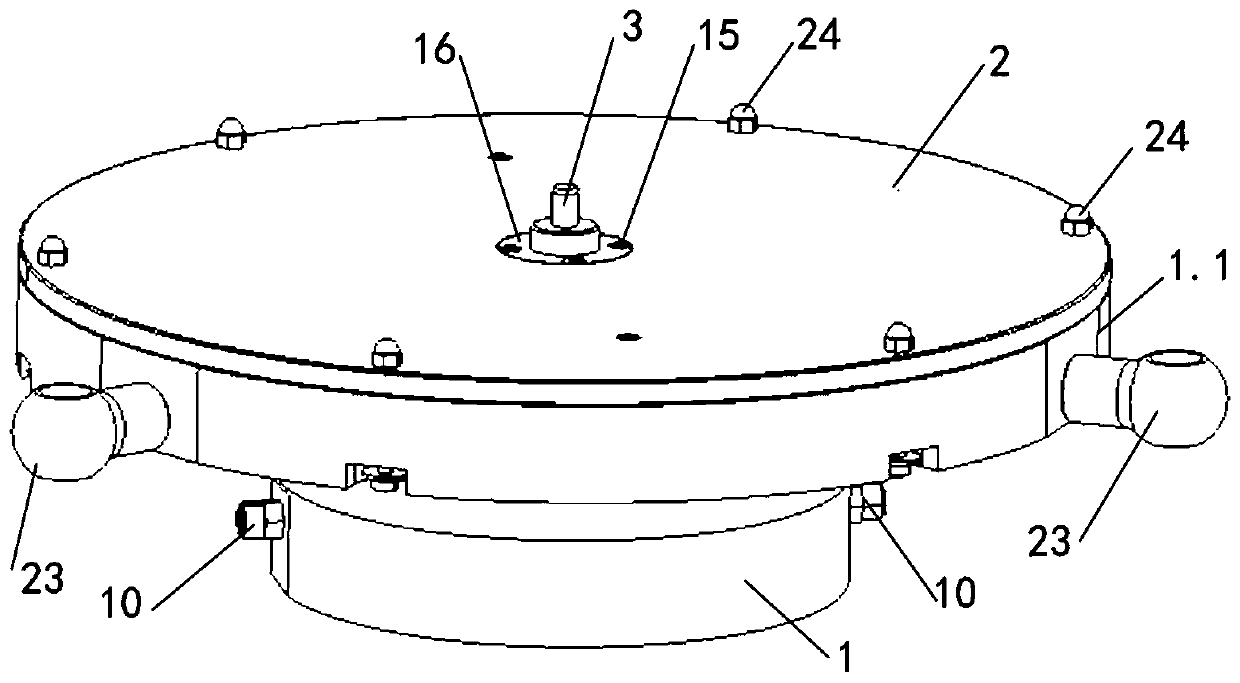

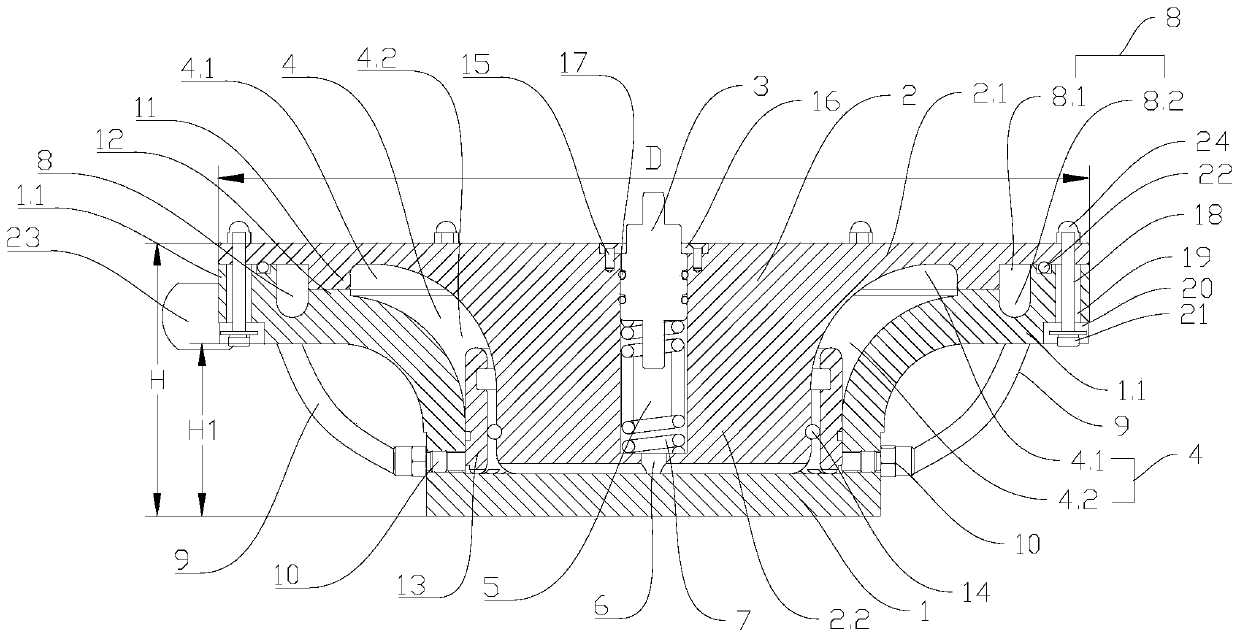

[0034] Such as Figure 1-Figure 3 As shown, this embodiment provides a self-adaptive suspension centering device for mold assembly, including a bearing base 1, a bearing plate 2 and a plunger 3, a hydraulic chamber 4 is provided between the bearing base 1 and the bearing plate 2, and the bearing plate 2 A plunger chamber 5 is provided, and a through hole 6 connecting the plunger chamber 5 and the hydraulic chamber 4 is provided on the carrier plate 2. Specifically, the through hole 6 is arranged at the lower end of the plunger chamber 5, and the plunger 3 and the plunger chamber 5 Sliding fit, the upper end of the plunger chamber 5 on the carrier plate 2 is provided with a limit structure, and a spring 7 is provided between the lower end of the plunger 3 and the plunger chamber 5;

[0035] The carrier plate 2 includes a support plate 2.1 and an extension portion 2.2 extending from the support plate 2.1 toward the carrier seat 1. The support plate 2.1 is connected to the carrie...

Embodiment 2

[0041] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0042] A lining ring 13 is arranged inside the hydraulic chamber 4 , the extension part 2.2 is located in the lining ring 13 , and an O-ring 14 is arranged between the extension part 2.2 and the lining ring 13 .

[0043] The lining ring 13 is located in the hydraulic chamber 4, and an O-ring 14 is provided between the lining ring 13 and the extension part 2.2. The O-ring 14 divides the lower part and the upper part of the lining ring 13 into two spaces, and the plunger 3 moves down. The process increases the pressure of the space below the backing ring 13, and squeezes the O-ring 14 under the condition that the pressure in the lower space of the backing ring 13 increases, so that there is a gap between the O-ring 14 and the backing ring 13, and the backing ring The hydraulic oil in the lower space of 13 flows into the upper space of the lining ring 13 from the gap, and then flow...

Embodiment 3

[0046] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

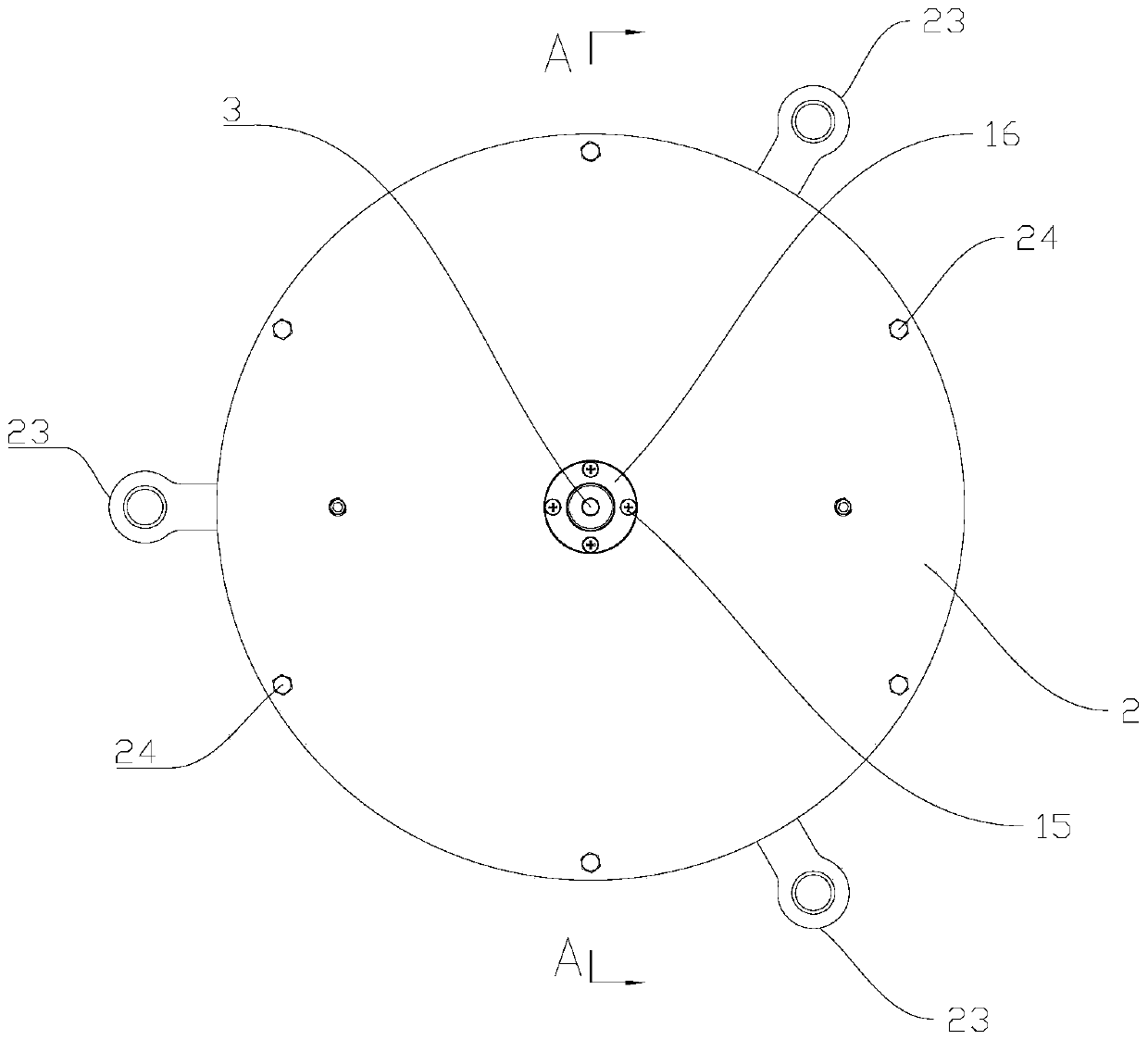

[0047] The limit structure includes a limit ring 16 fixed on the carrier plate 2 by a screw 15, the inner diameter of the limit ring 16 is smaller than the outer diameter of the plunger 3 in the plunger cavity 5, and the plunger 3 stretches out of the plunger cavity 5 The part is slidingly fitted with the limit ring 16.

[0048] Limiting ring 16 is used to limit the moving path of plunger 3, and the upper end that is positioned at plunger chamber 5 is provided with mounting groove on the carrier plate 2, and limit ring 16 is located in the mounting groove, and the upper end surface of limit ring 16 and carrying plate The upper end surface of 2 is flush, and a plurality of screws 15 are evenly provided along the circumferential direction of the axis of the plunger chamber 5, and four screws 15 are provided in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com