Oil return control method for an air-conditioning compressor unit

A compressor unit and oil return control technology, which is applied in the direction of compressors, refrigerators, refrigeration components, etc., can solve the problems of ignoring the operation status of the unit, unfavorable unit operation stability and high-efficiency and high-quality oil return, so as to improve the operation stability and The effect of oil return efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides an oil return control method of an air conditioner compressor unit, which judges whether the operation state of the compressor unit reaches the set oil return condition according to the operation parameters of the compressor unit, and when the operation state of the compressor unit reaches the set oil return condition , to control the compressor unit to run in the oil return mode. The following will be described in conjunction with specific embodiments.

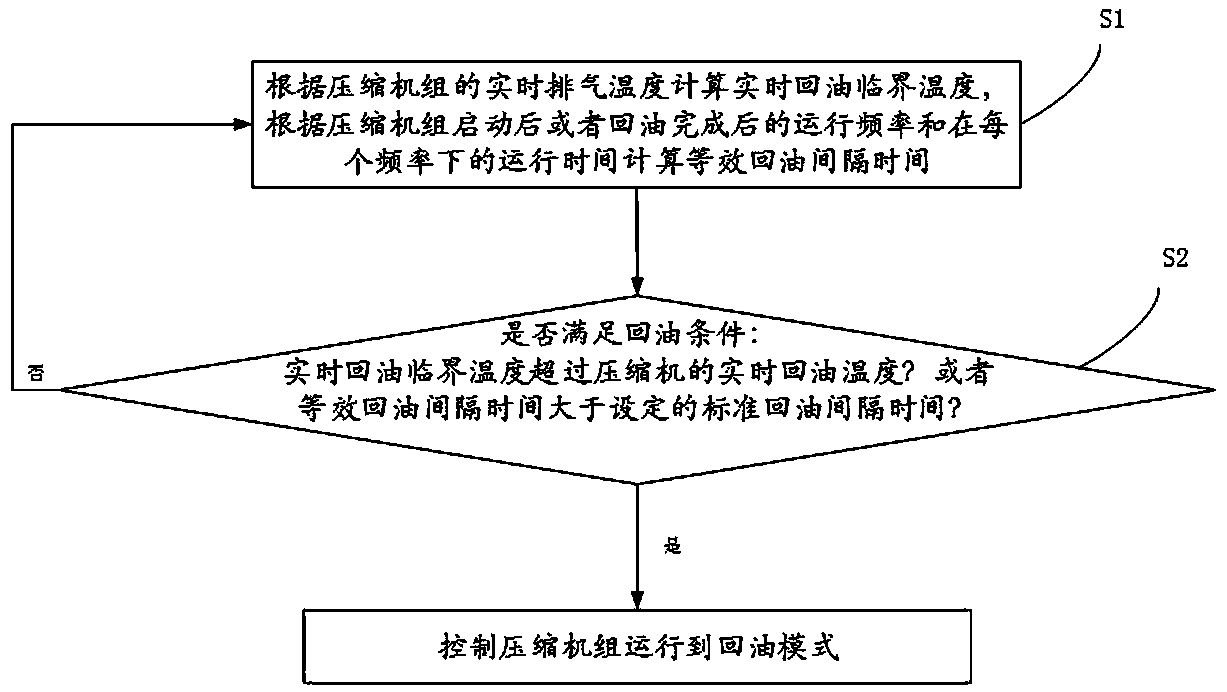

[0024] Such as figure 1 As shown, in Embodiment 1 of the present invention, the oil return control method of the air-conditioning compressor unit includes:

[0025] Step S1: Calculate the real-time oil return critical temperature according to the real-time exhaust temperature of the compressor unit, and calculate the equivalent oil return interval time according to the operating frequency of the compressor unit after starting or after the oil return is completed and the operating time at each fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com