A floating oil recovery device

An oil slick recovery and oil tank technology, which is applied in general water supply conservation, water conservancy projects, and open-air water surface cleaning, etc., can solve problems such as reducing oil return efficiency, and achieve the effect of high oil return efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

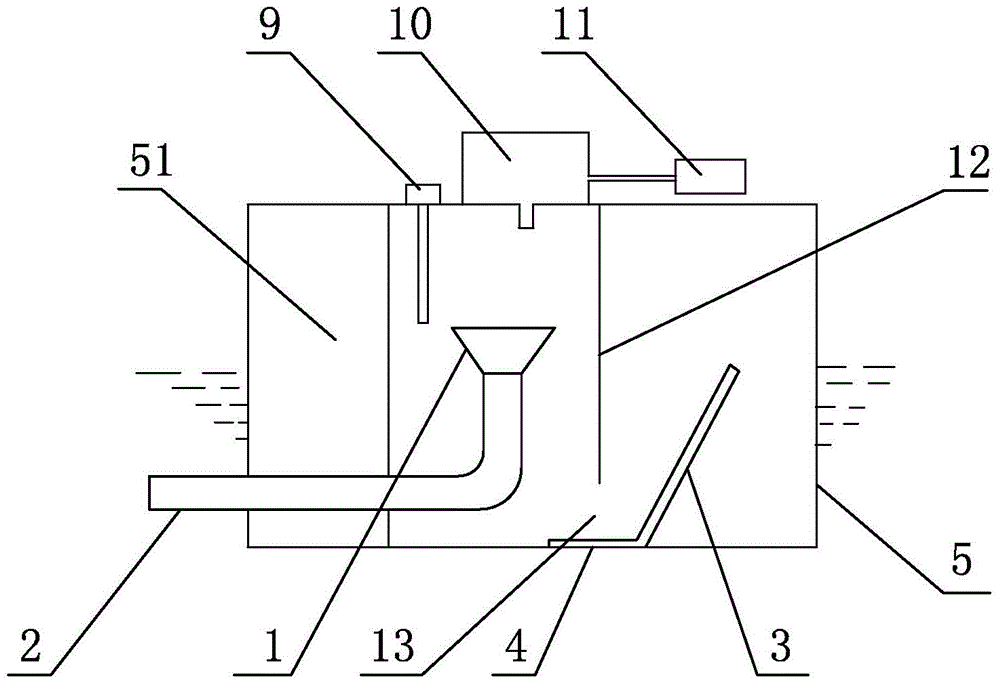

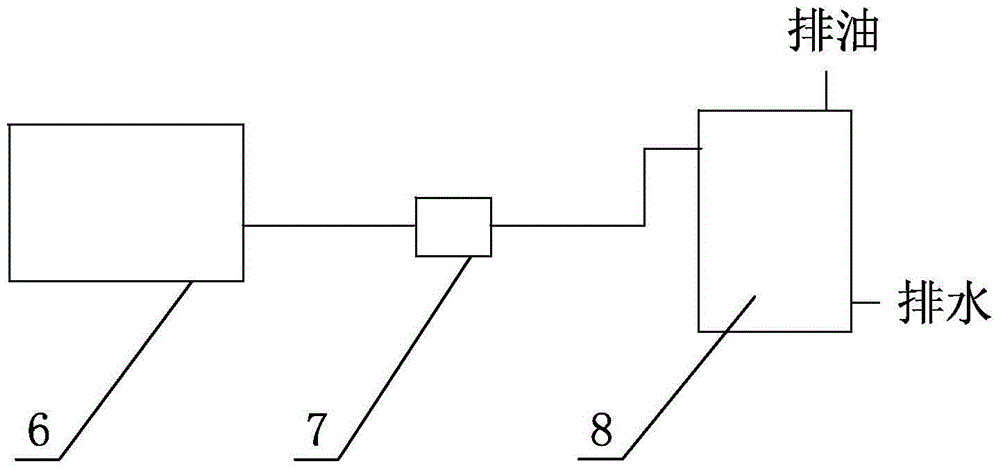

[0013] Embodiment: a kind of floating oil recovery device of the present invention, as attached figure 1 , attached figure 2 As shown, it includes an oil absorber 6, a pump 7, an oil-water separator 8, and the oil absorber 6 includes a floating oil tank 5, an inclined baffle plate 3, a bottom plate 4, an oil suction pan 1, an oil suction pipe 2, and a control system.

[0014] A partition 12 is arranged in the floating oil tank 5; the top and side of the partition 12 are all connected with the floating oil tank 5, and the channel opening 13 for oil liquid entry is arranged between the bottom end and the bottom of the floating oil tank 5, and the channel opening 13 lower than the top of the slanted baffle 3, the top of the slanted baffle 3 is lower than the suction port of the oil suction pan 1; On the side, the vacuum box 10 communicates with the floating oil tank 5. Under the action of vacuum, the oil return liquid level in the cavity where the oil suction plate is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com