Energy and water saving type hot water spraying and defrosting system

A hot water spray and water-saving technology, applied in defrosting, lighting and heating equipment, damage protection, etc., can solve the problems of high energy consumption in defrosting, improve oil return efficiency, reduce design area, and improve heat transfer performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

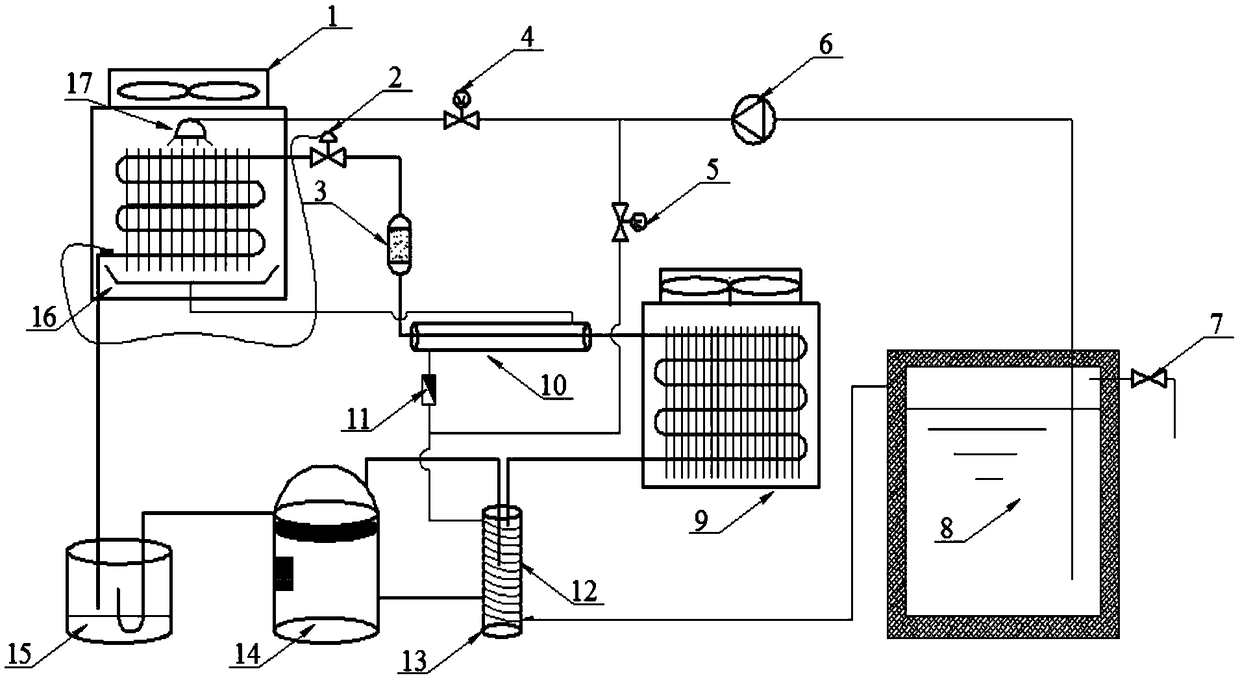

[0018] Such as figure 1 As shown, an energy-saving and water-saving hot water spray defrosting system is based on the refrigeration system, and uses the high-efficiency cascade utilization of waste heat in the refrigeration system as a technical means to achieve beneficial effects such as performance optimization of the refrigeration system, high-efficiency energy-saving defrosting, and water conservation. .

[0019] An energy-saving and water-saving hot water spray defrosting system based on a refrigeration system, including a finned tube evaporator 1, a thermal expansion valve 2, a dry filter 3, a first solenoid valve 4, a second solenoid valve 5, and a water pump 6 , safety valve 7, adiabatic water storage tank 8, air-cooled condenser 9, casing heat exchanger 10, one-way valve 11, serpentine coil 12, oil separator 13, compressor 14, gas-liquid separator 15, Water coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com