Automatic dehydrating and oil returning system for siphoning type oil tank and oil returning method

An oil return system, siphon type technology, applied in the field of oil tank oil return system, can solve the problems of oil and water mixing together, unstable oil-water interface, etc., and achieve the effects of improving efficiency, long service life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

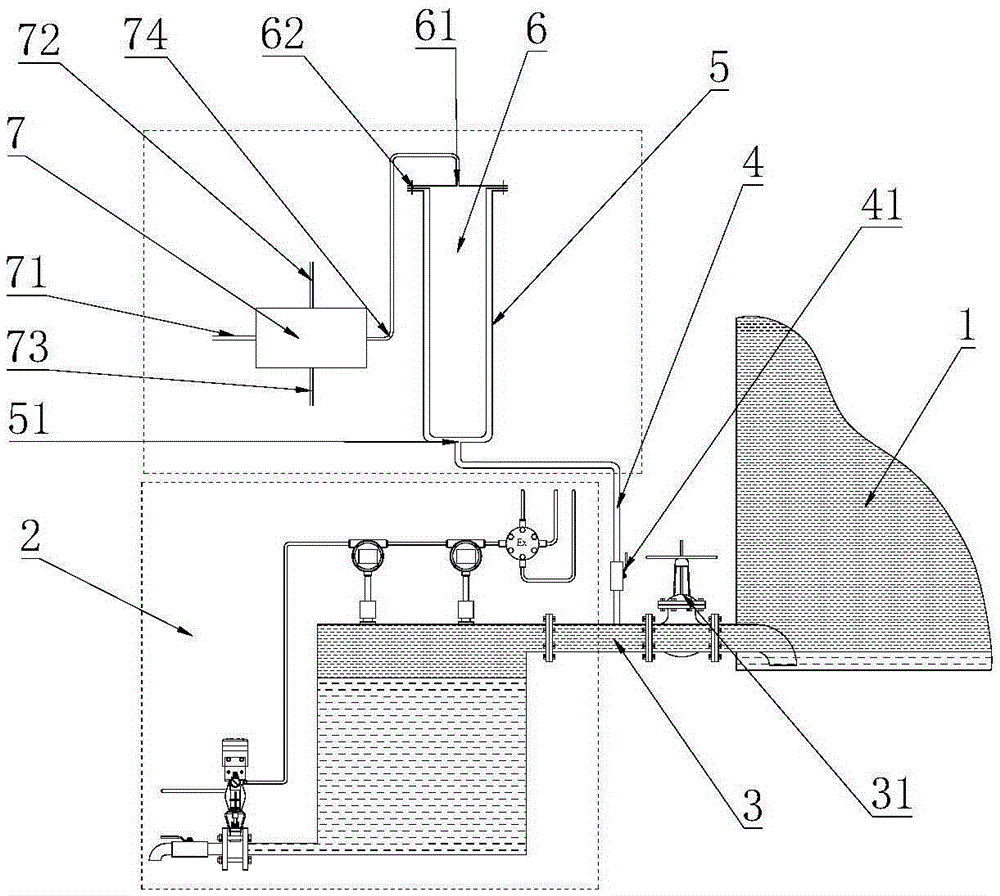

[0047] like figure 1 The siphon type oil tank automatic dehydration and oil return system of the present invention includes an oil tank 1, a dehydrator 2, a dehydration pipeline 3 for connecting the oil tank 1 and the dehydrator 2, and an oil return system. The oil return system passes through the connecting pipeline 4 communicates with the dehydration pipeline 3 , and the connection port between the connection pipeline 4 and the dehydration pipeline 3 is arranged on the top wall of the dehydration pipeline 3 .

[0048] The oil return system includes a buffer tank 5, a soft capsule 6, a control device 7 for controlling the increase or decrease of the air pressure in the buffer tank, the soft capsule 6 is provided with an air chamber, and the soft capsule 6 is arranged on the In the buffer tank 5 , the buffer tank 5 and the soft capsule 6 are hermetically connected through a mounting flange 62 , the soft capsule 6 is provided with an air filling port 61 , and the buffer tank 5 ...

Embodiment 2

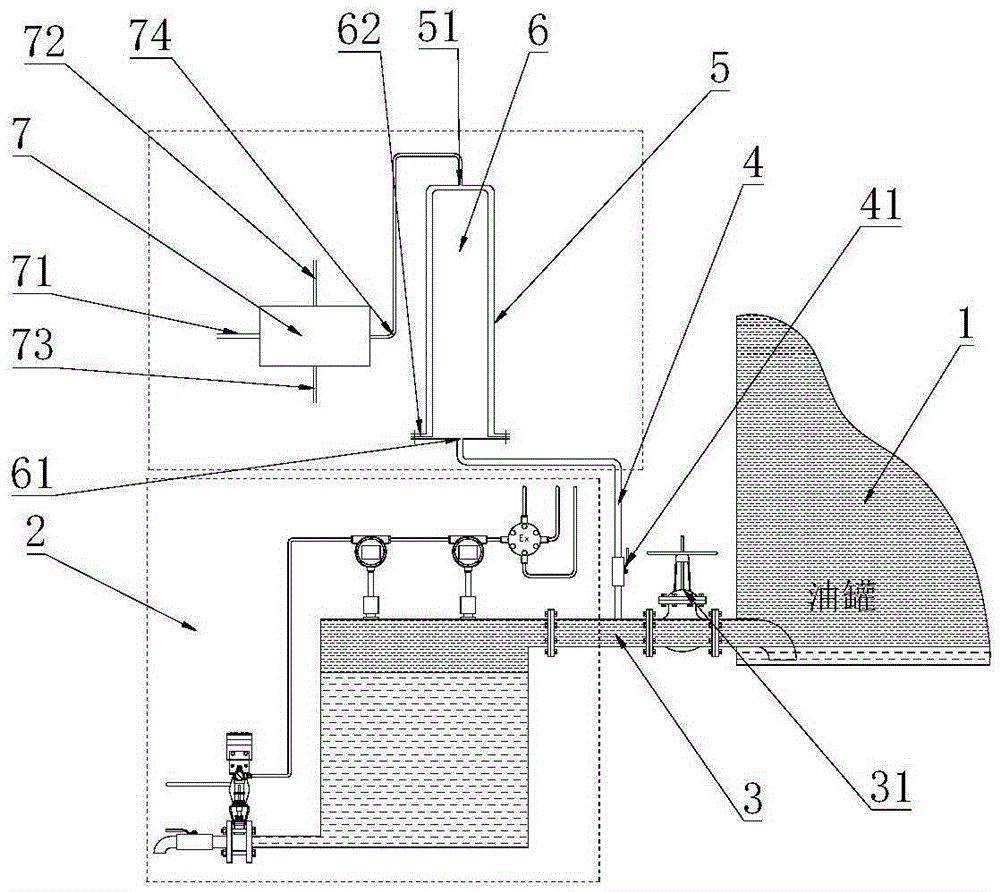

[0058] like figure 2 As shown, the siphon type oil tank automatic dehydration oil return system described in this embodiment, except for the connection direction of the oil return system, other structures and working principles are the same as those in the first embodiment. The inflation port 61 of the soft capsule 6 is connected to the connecting pipe 4 , and the gas outlet 51 of the buffer tank 5 is connected to the control channel 74 of the pressure controller 7 .

[0059] A method for automatically dehydrating and returning oil to a siphon type oil tank, comprising the following steps:

[0060] S1. The controller 73 controls the conduction of the air intake channel 71, inflates the buffer tank 5, squeezes the soft capsule 6, makes the soft capsule 6 shrink, and discharges the oil in the soft capsule 6 to the oil tank 1.

[0061] S2. The controller 73 closes the air intake channel 71, opens the exhaust channel 72, and discharges the gas in the buffer tank 5, the pressure ...

Embodiment 3

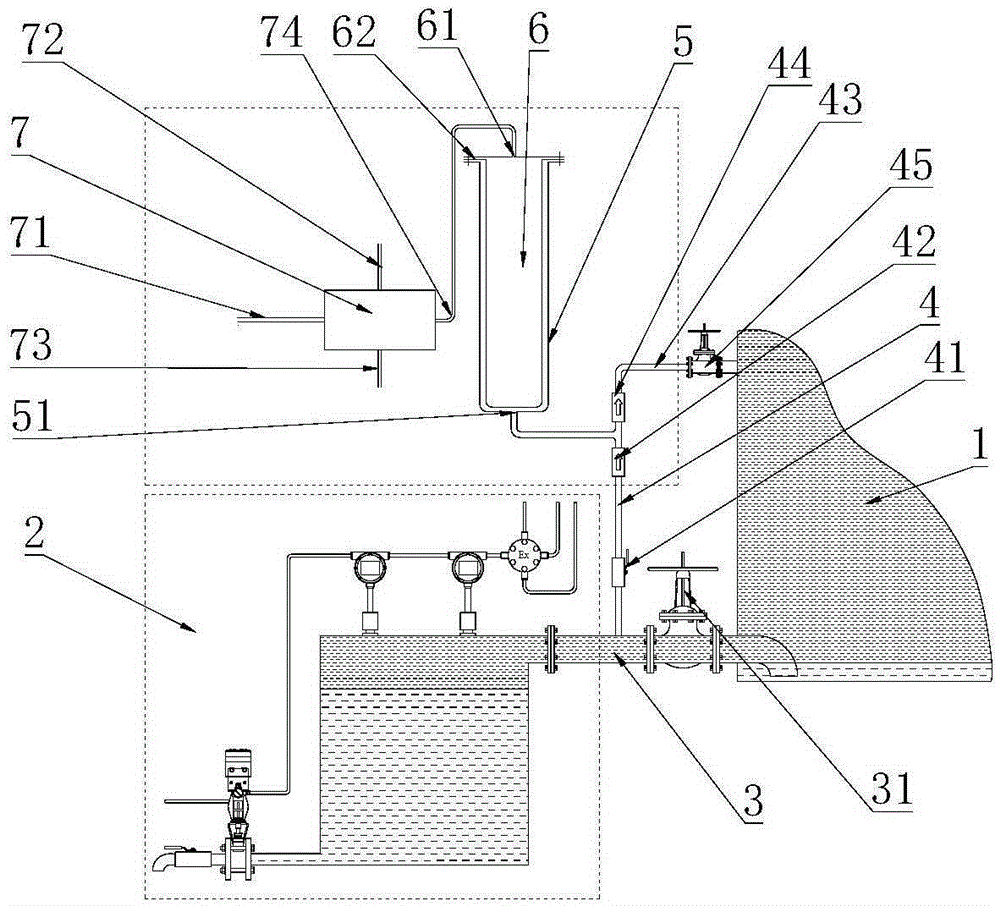

[0066] like image 3 As shown, the siphon type oil tank automatic dehydration oil return system described in this embodiment, except for the oil return channel of the oil return system, other structures and working principles are the same as those in the first embodiment. The control passage 4 is provided with a first one-way valve 42, and the first one-way valve 42 leads from the deoiling passage to the oil return system. It also includes an oil return pipeline 43. One end of the oil return pipeline 43 is arranged on the control channel 4 between the first one-way valve 42 and the buffer tank 5, and the other end is connected to the oil tank 1. On the oil return pipeline 43 A second one-way valve 44 is provided, and the second one-way valve 44 leads from the buffer tank 5 to the oil tank 1 . The oil return passage 43 is provided with an oil return switch valve 45 .

[0067] A method for automatic dehydration and oil return of a siphon type oil tank, the steps are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com