Corn paste stuffing and production method thereof

A corn and stuffing technology, applied in baking, baked goods, food science and other directions, can solve the problems of low nutritional retention, no physical feeling, inconvenient for customers to use, etc., and achieve the effect of good taste and unique nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

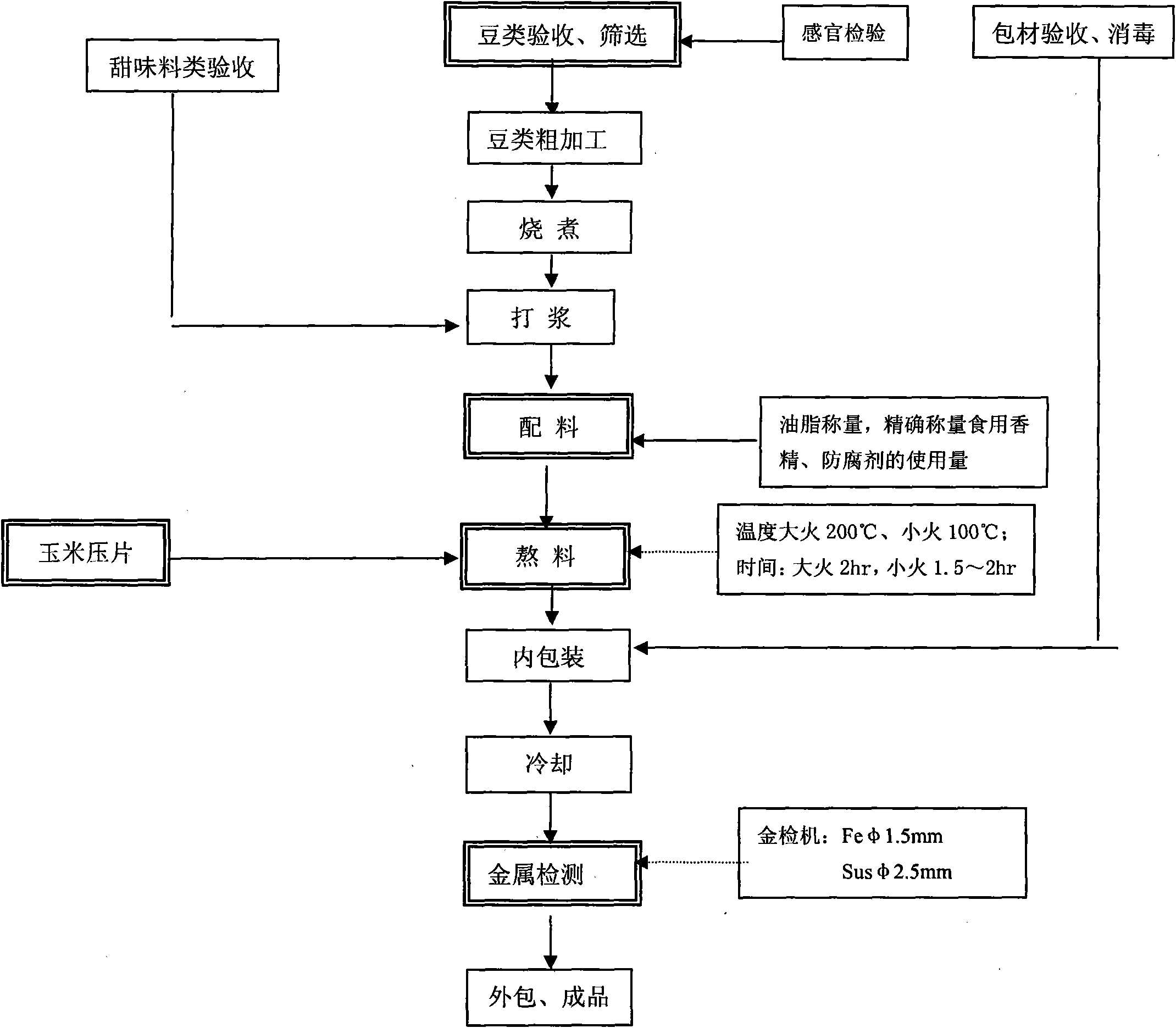

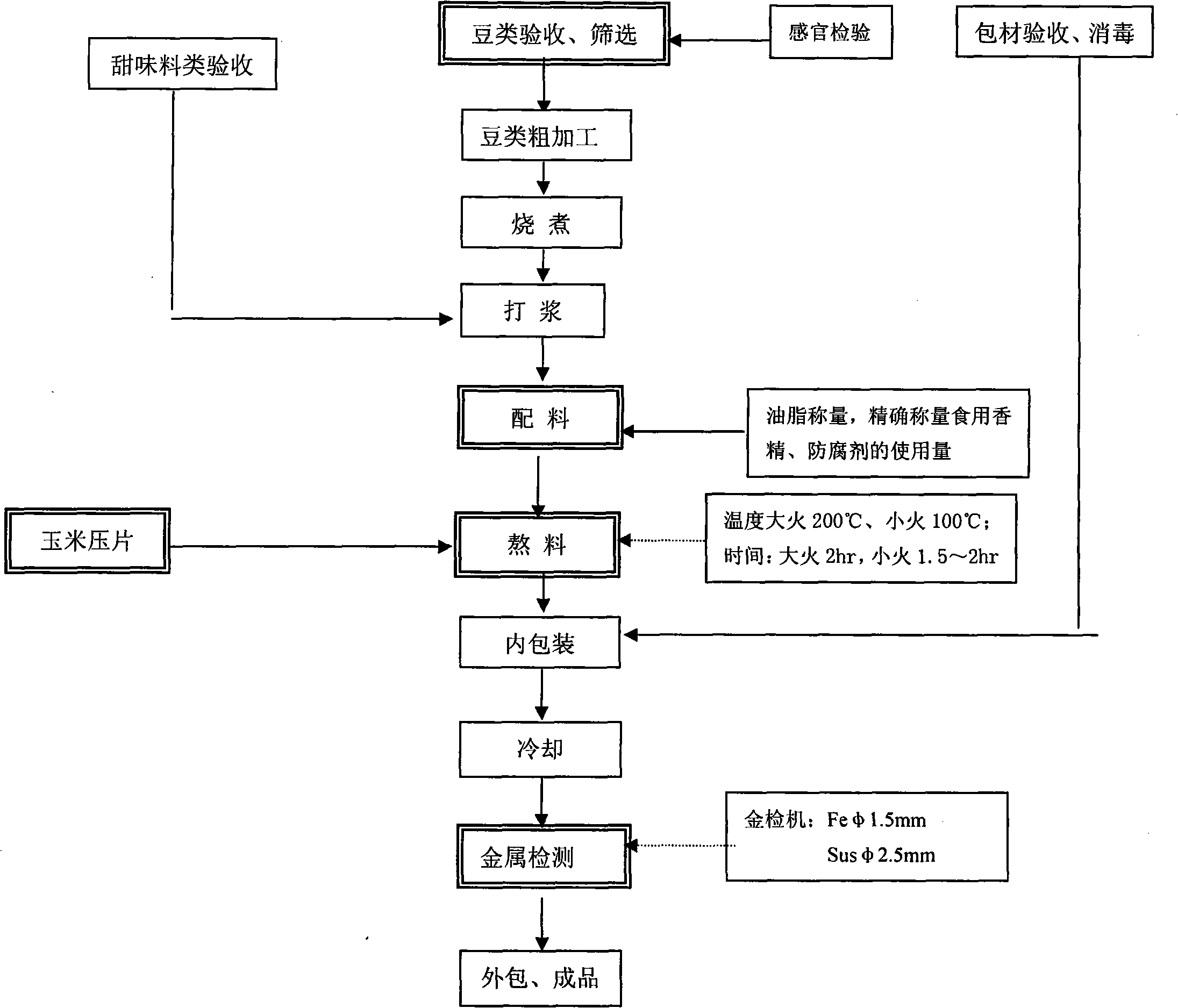

Image

Examples

Embodiment 1

[0030] Prepare the following raw materials and accessories:

[0031] Beans 21Kg

[0032] Corn 30Kg

[0033] Sweetener 34Kg

[0034] Grease 14.65Kg

[0035] Food flavor 0.3Kg

[0036] Preservative 0.05Kg

[0037] The above-mentioned beans are large kidney beans or small kidney beans, or a mixture of the two.

[0038] The above-mentioned sweetener is white granulated sugar or soft white sugar or glucose syrup, or a mixture of two or more of white granulated sugar, soft white sugar and glucose syrup.

[0039] The above-mentioned fats are salad oil or butter or ghee, or a mixture of two or three kinds of fats.

[0040] The above-mentioned edible essence is corn essence.

[0041] The above-mentioned preservative is potassium sorbate or sodium dehydroacetate, or a mixture of the two.

[0042] The processing steps are as follows:

[0043] (1) Acceptance and treatment of the above-mentioned raw materials, including rough processing of beans washed and peeled;

[0044] (2) co...

Embodiment 2

[0053] Prepare the following raw materials and accessories

[0054] Beans 29Kg

[0055] Corn 26Kg

[0056] Sweetener 32Kg

[0057] Grease 12.5Kg

[0058] Food flavor 0.4Kg

[0059] Preservative 0.1Kg

[0060] The above-mentioned beans are large kidney beans or small kidney beans, or a mixture of the two.

[0061] The above-mentioned sweetener is white granulated sugar or soft white sugar or glucose syrup, or a mixture of two or more of white granulated sugar, soft white sugar and glucose syrup.

[0062] The above-mentioned fats are salad oil or butter or ghee, or a mixture of two or three kinds of fats.

[0063] The above-mentioned edible essence is corn essence.

[0064] The above-mentioned preservative is potassium sorbate or sodium dehydroacetate, or a mixture of the two.

[0065] Processing steps are identical with embodiment one.

Embodiment 3

[0067] Prepare the following raw materials and accessories

[0068] Beans 22Kg

[0069] Corn 26Kg

[0070] Sweetener 35Kg

[0071] Grease 16.61Kg

[0072] Food flavor 0.35Kg

[0073] Preservative 0.04Kg

[0074] The above-mentioned beans are large kidney beans or small kidney beans, or a mixture of the two.

[0075] The above-mentioned sweetener is white granulated sugar or soft white sugar or glucose syrup, or a mixture of two or more of white granulated sugar, soft white sugar and glucose syrup.

[0076] The above-mentioned fats are salad oil or butter or ghee, or a mixture of two or three kinds of fats.

[0077] The above-mentioned edible essence is corn essence.

[0078] The above-mentioned preservative is potassium sorbate or sodium dehydroacetate, or a mixture of the two.

[0079] Processing steps are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com