Oil eliminator auxiliary device of air conditioning system and control method thereof

An oil separator and auxiliary device technology, which is applied to the components of pumping devices for elastic fluids, machines/engines, liquid variable capacity machines, etc. Foreign matter clogging and other problems, to increase the cooling and heating capacity, improve the effect of EER/COP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

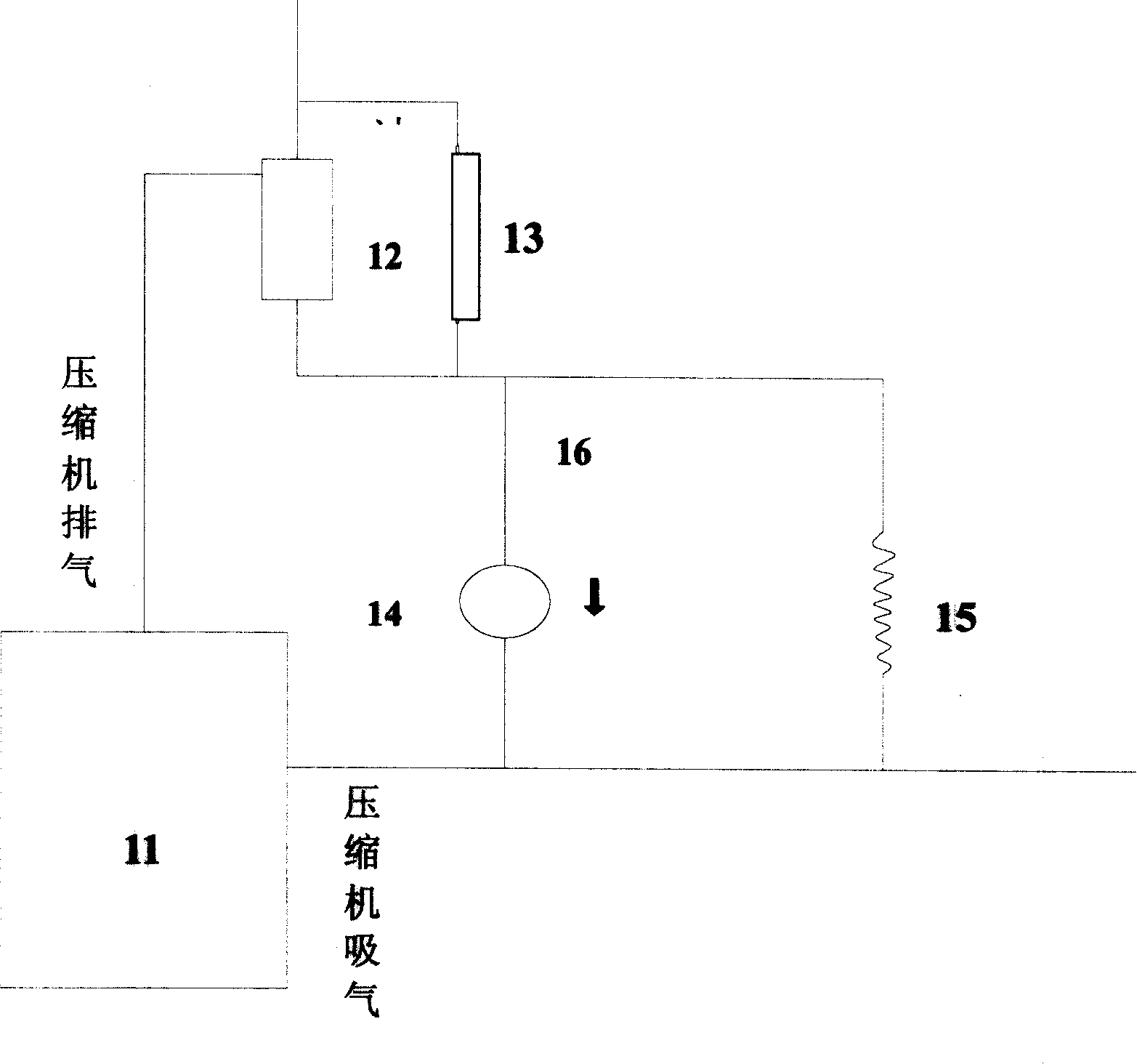

[0036] The present invention is described in detail below in conjunction with accompanying drawing, figure 1 It is a schematic diagram of the oil separator auxiliary device of the present invention. As shown in the figure, a solenoid valve is connected in series with a branch pipe 16 between the oil outlet of the oil separator 13 on the exhaust side of the compressor 11 and the suction pipe of the compressor 11. Valve 14, the solenoid valve 14 has the characteristics of the unloading valve in the air conditioning system, so after using this device, the unloading valve in the system can be combined with the solenoid valve 14 in the device, and it is controlled by the program to realize unloading or return. The function of the oil; the oil return capillary in the device passes through the branch pipe 16 and is connected in parallel with the solenoid valve on the same circuit.

[0037] The air-conditioning system oil separator auxiliary device and the oil return control method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com