Sealing component

A technology of sealing components and sealing lips, which is applied in the direction of engine components, engine sealing, mechanical equipment, etc., can solve the problems of difficult processing and production, and the inability to add oil return channels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

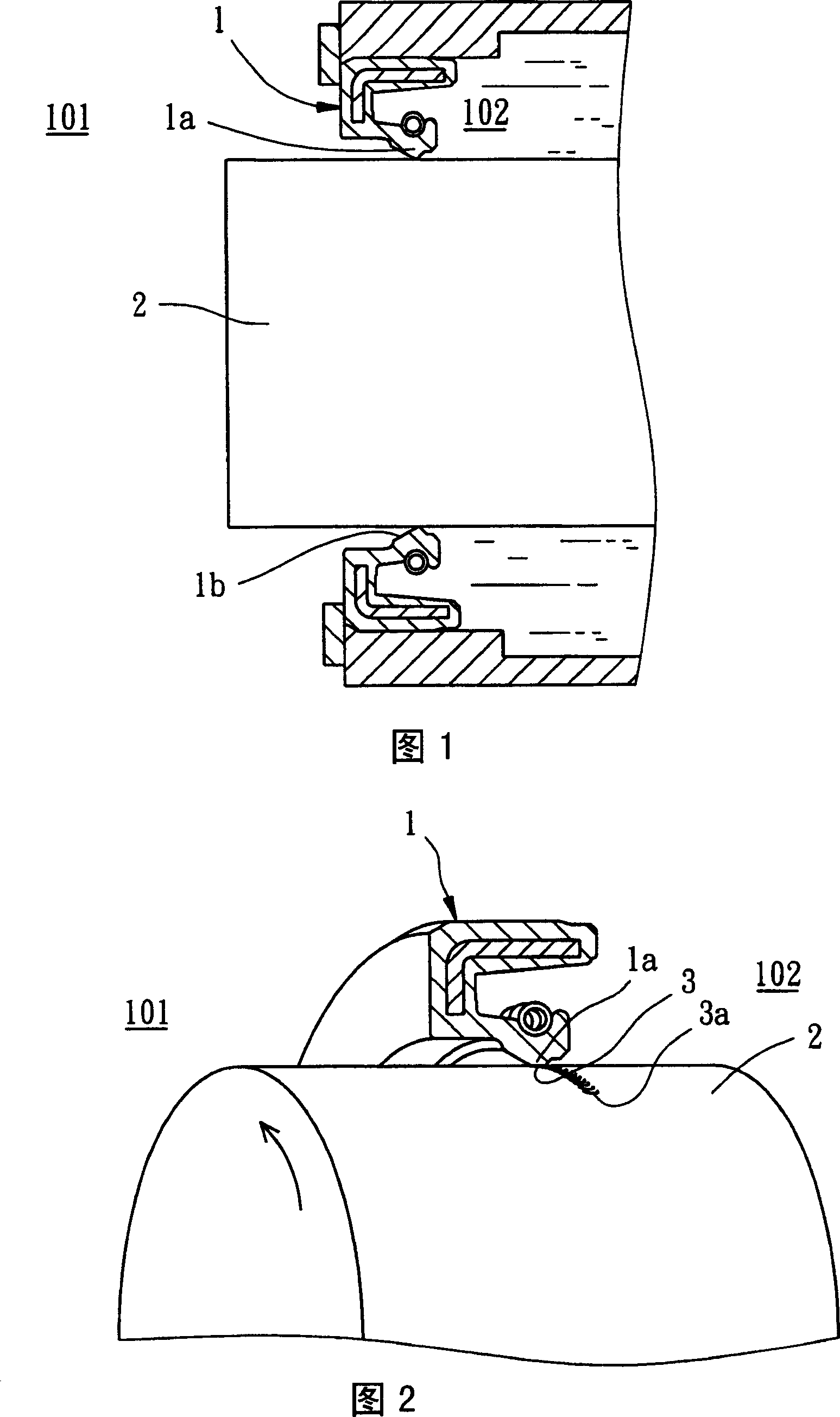

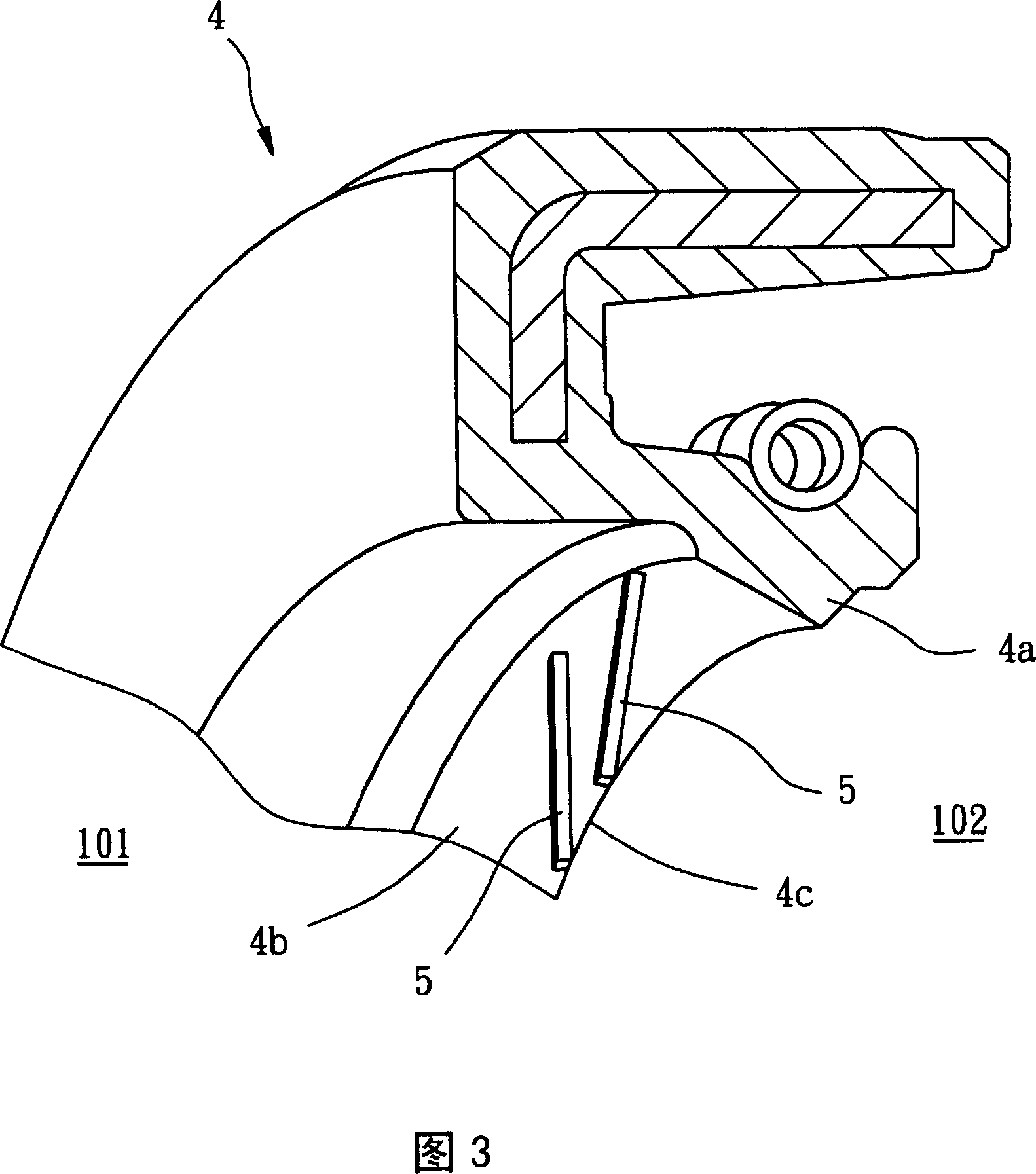

[0048] 8 and 9 are schematic diagrams of an application example of a sealing element 100 in a preferred embodiment of the present invention, revealing that the sealing element 100 is sleeved on a rotating shaft 200 rotating counterclockwise, and is located between the rotating shaft 200 and an oil groove. 300 , which is mainly used to isolate the air from the lubricating oil in the oil tank 300 , one side of the sealing element 100 is the air side 101 , and the other side is the oil side 102 .

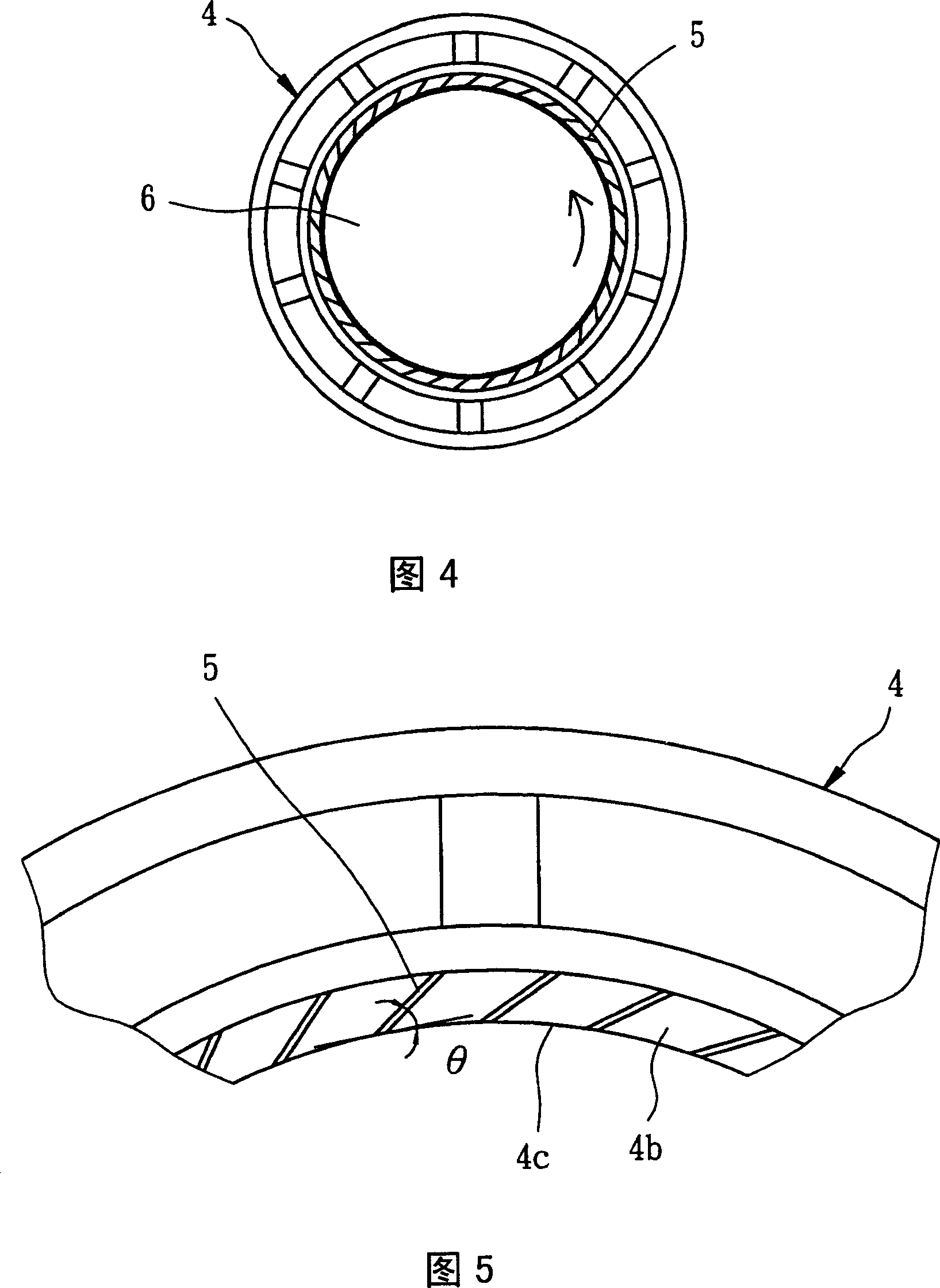

[0049] Please refer to FIG. 10 , the sealing element 100 of the foregoing embodiment includes a circular frame body 10, an annular body 12, a sealing lip 14, a spring ring 16 and a plurality of oil return grooves 18, wherein the annular body 12, the sealing The lip 14 and the oil return groove 18 are integrally formed of rubber material, and the structure of each part is described below:

[0050] The circular frame body 10 is made of metal and serves as the main support body of the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com