Oil passage balance system of dual parallel compressor screw water chilling unit

A chiller and dual-compressor technology, which is applied in the direction of compressors, refrigeration components, refrigerators, etc., can solve the problems of difficult realization, high difficulty in assembly, lack of oil in the compressor, etc., so as to avoid unit failure and achieve good oil return effect , The effect of oil circuit balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

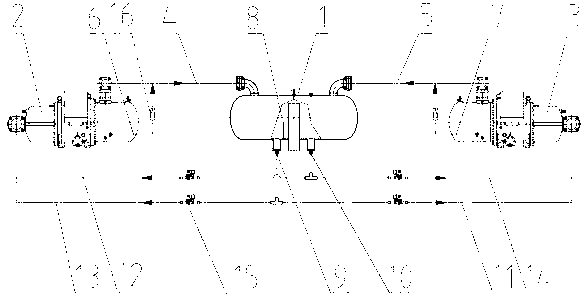

[0013] As shown in the figure: a dual-compressor parallel screw chiller oil circuit balance system, including two parallel compressors and an external shared secondary oil separator 1, the two compressors are respectively the first compressor 2 and a second compressor 3, the first compressor 2 is provided with a first exhaust pipe 4 for exhaust, and the second compressor 3 is also provided with a second exhaust pipe 5 for exhaust, Both the first exhaust pipe 4 and the second exhaust pipe 5 communicate with the secondary oil separator 1, and the first compressor 2 and the second compressor 3 are respectively provided with outlets for deriving excess lubricating oil. The first overflow pipe 6 and the second overflow pipe 7, the first overflow pipe 6 communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com