Loop heat pipe type heating and refrigerating air conditioning system

An air-conditioning system, loop heat pipe technology, applied in the direction of air-conditioning systems, refrigerators, heating methods, etc., can solve the problem of high resistance of the refrigerant along the way, to improve the heating or cooling effect, improve stability, and reduce resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

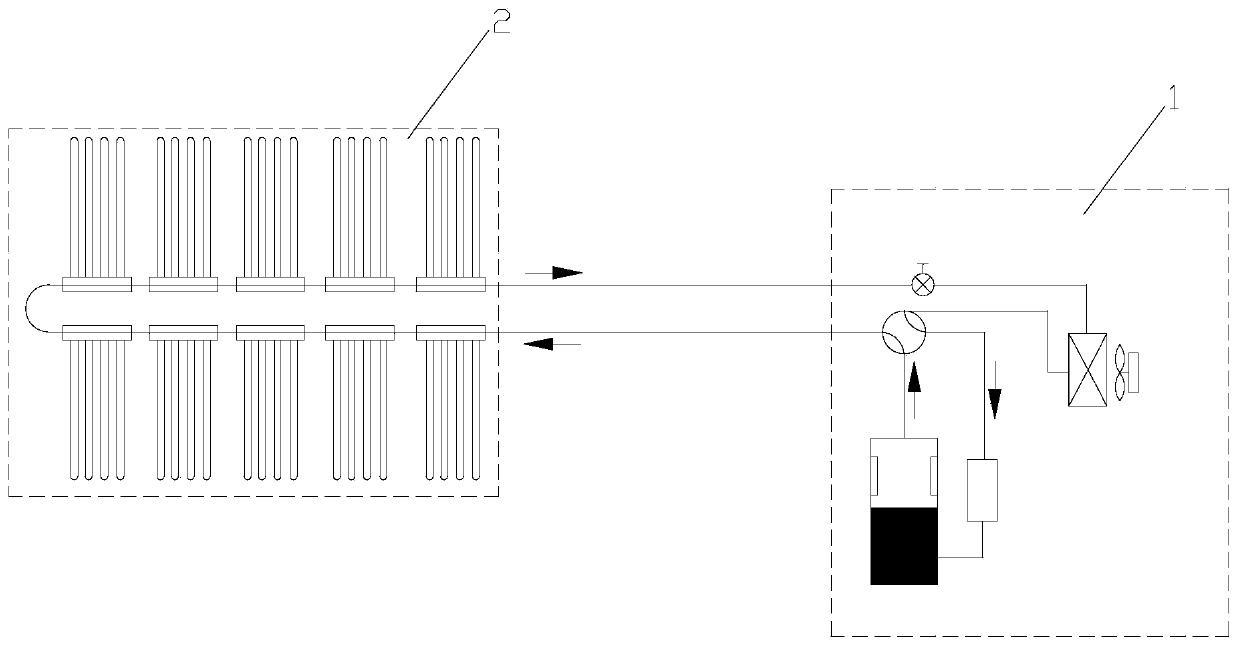

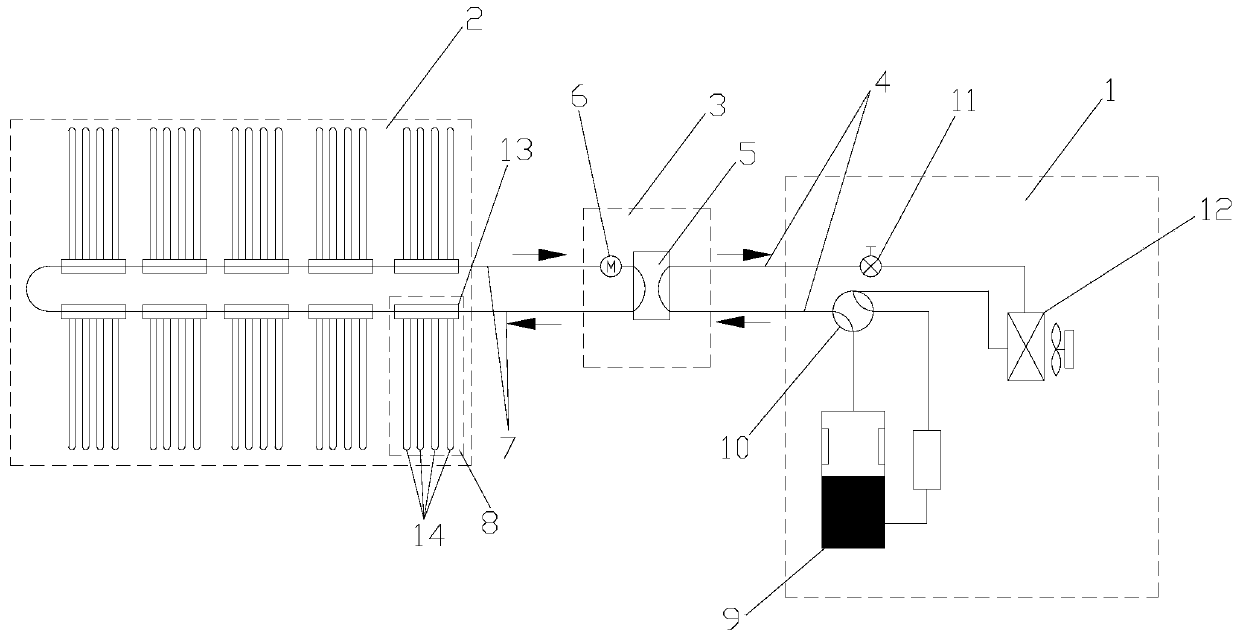

[0060] This example illustrates the loop heat pipe heating and air-conditioning system as an example. image 3 As shown, the loop heat pipe heating and air conditioning system described in this embodiment includes: a heating cycle unit 1, a loop heat pipe unit 2 and an intermediate heat exchange unit 3, and the heating cycle unit 1 has a first refrigerant, the loop heat pipe unit 2 has a second refrigerant;

[0061] The heating cycle unit 1 is used to form a heating cycle of the first refrigerant;

[0062] The loop heat pipe unit 2 is used to condense and release heat after the second refrigerant absorbs heat;

[0063] The intermediate heat exchange unit 3 is used for refrigerant heat exchange between the first refrigerant in the heating cycle unit 1 and the second refrigerant in the loop heat pipe unit 2 .

[0064] Among them, the heating cycle unit 1 is connected to the loop heat pipe unit 2 through the intermediate heat exchange unit 3, the heating cycle unit 1 forms a he...

Embodiment 2

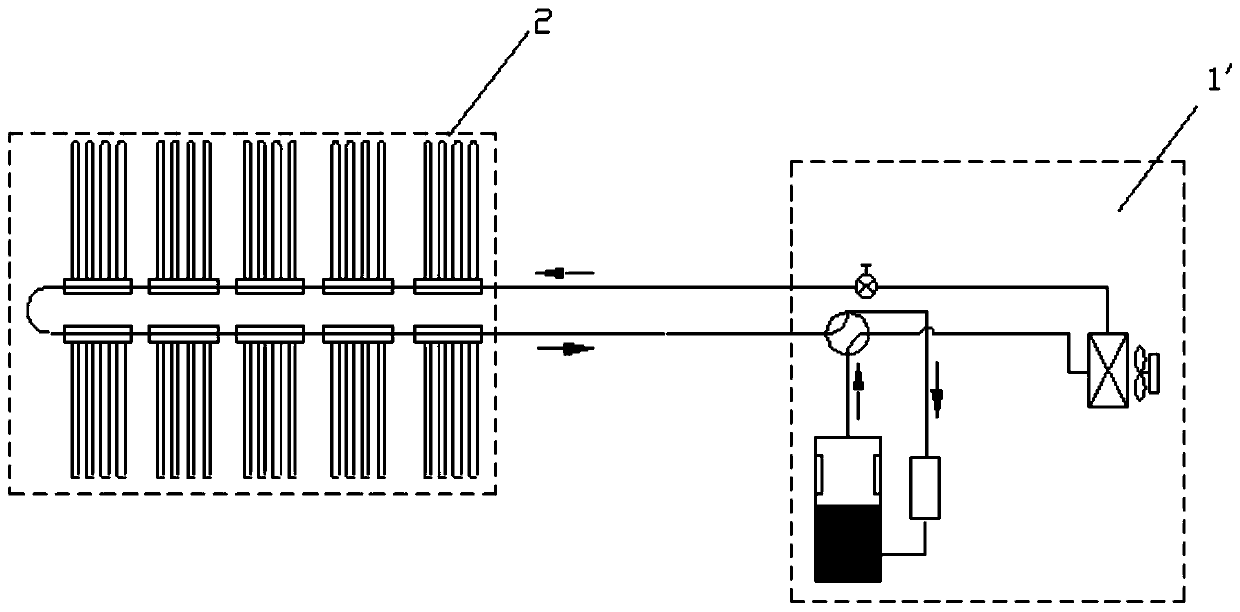

[0088] In this embodiment, the loop heat pipe refrigeration and air-conditioning system is illustrated with an example, such as Figure 8 As shown, the loop heat pipe refrigeration and air-conditioning system described in this embodiment includes: a refrigeration cycle unit 1 ′, a loop heat pipe unit 2 and an intermediate heat exchange unit 3 , and the refrigeration cycle unit 1 ′ has a first Refrigerant, the loop heat pipe unit 2 has a second refrigerant;

[0089] The refrigeration cycle unit 1' is used to form a refrigeration cycle of the first refrigerant;

[0090] The loop heat pipe unit 2 is used for evaporating and absorbing heat after the second refrigerant is condensed;

[0091] The intermediate heat exchange unit 3 is used for heat exchange between the first refrigerant in the refrigeration cycle unit 1 ′ and the second refrigerant in the loop heat pipe unit 2 .

[0092] In this embodiment, the refrigeration cycle unit 1' is connected to the loop heat pipe unit 2 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com