Oil ring of piston ring set of internal combustion engine

A technology for piston rings and internal combustion engines, applied to piston rings, mechanical equipment, engine components, etc., can solve the problems of poor oil scraping performance, achieve the effects of preventing oil leakage, good specific pressure distribution uniformity, and reducing oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

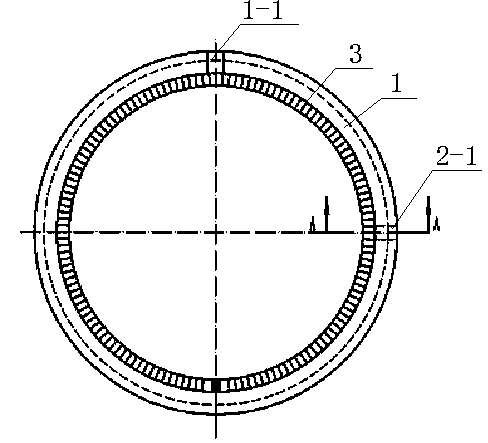

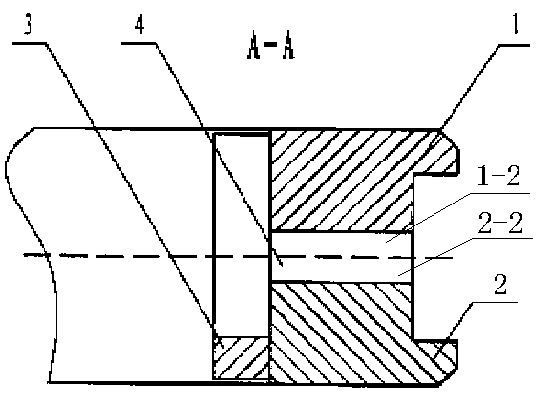

[0013] like figure 1 , 2 As shown, the present invention consists of an upper scraper ring 1 with an opening 1-1, a lower scraper ring 2 with an opening 2-1, and a wave-shaped support spring 3.

[0014] The upper oil scraper ring 1 and the lower oil scraper ring 2 made of alloy cast iron have the same height, and the upper oil scraper ring 1 or the lower oil scraper ring 2 accounts for 1 / 2 of the total height of the piston ring group oil ring.

[0015] The upper oil scraper ring 1 and the lower oil scraper ring 2 are stacked relative to each other, and the openings of the upper oil scraper ring 1 and the lower oil scraper ring 2 are staggered by 60° to 120°, and in this example, they are staggered by 90°. A wave-shaped support spring 3 is arranged on the inner circular surfaces of the two scraper rings 1 and 2 .

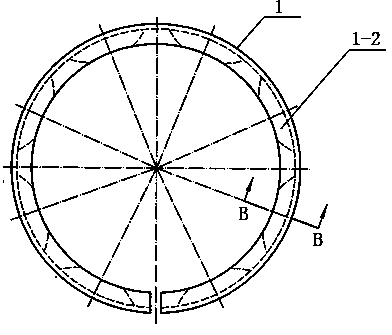

[0016] like figure 2 , 3 , 4, eight upper oil discharge grooves 1-2 are evenly distributed in the circumferential direction of the upper oil scraper ring 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com