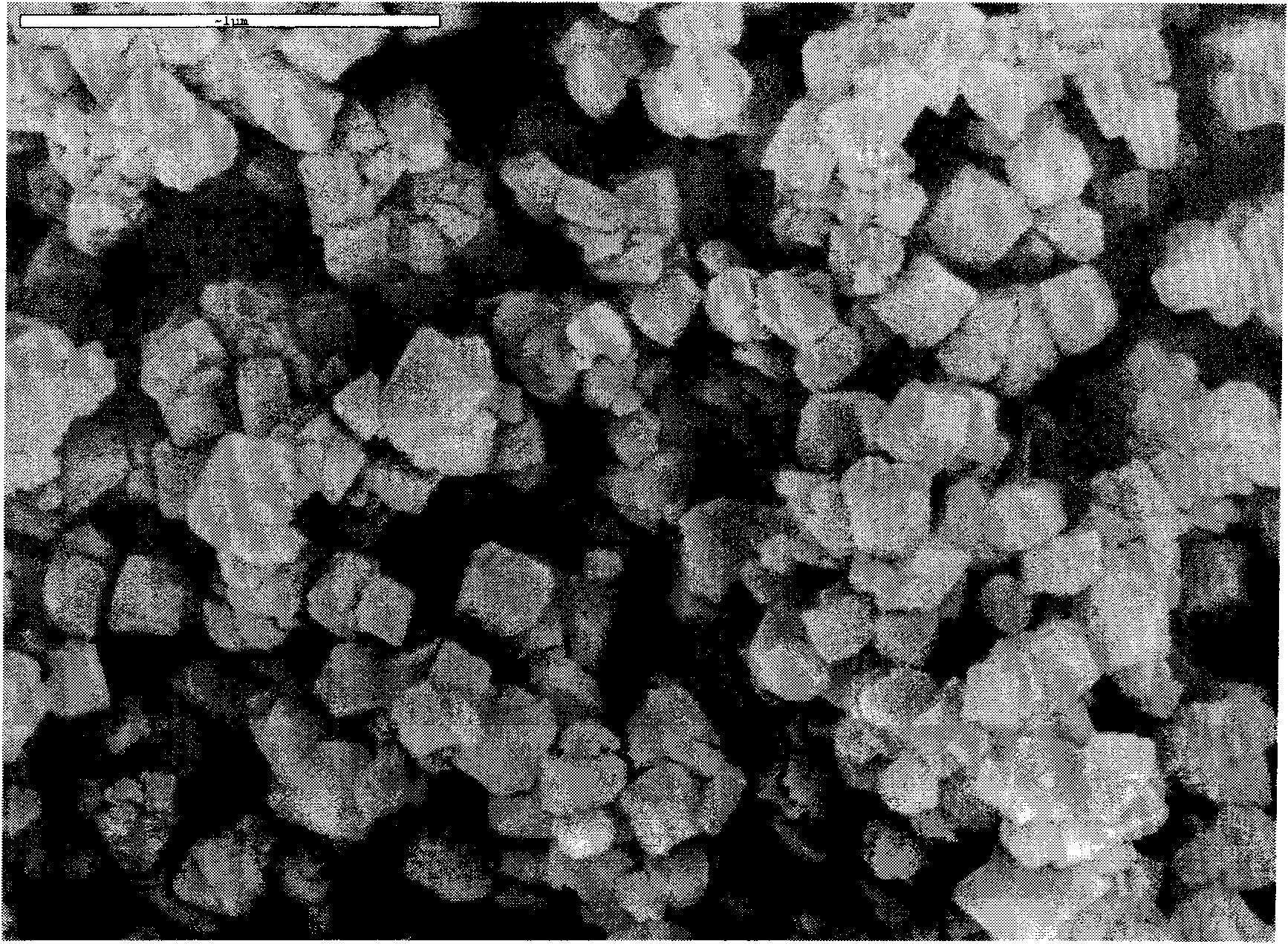

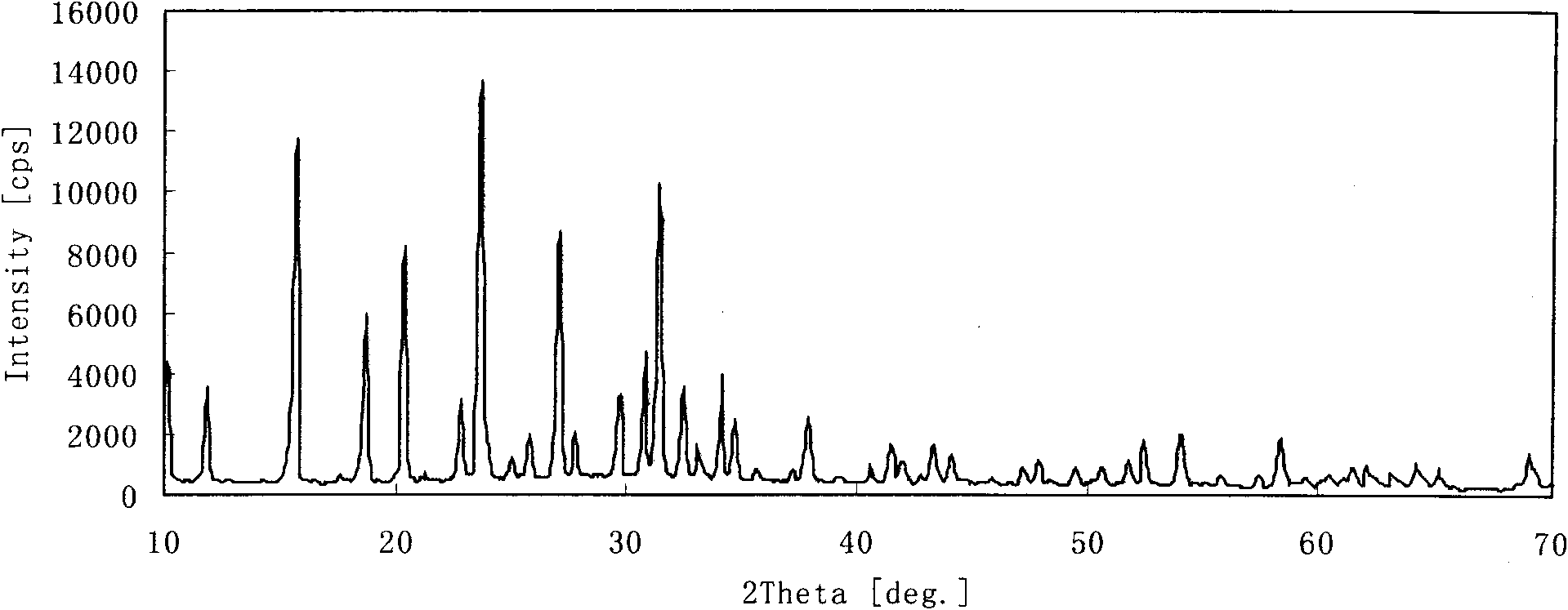

Small-grain high-Si Y-type molecular sieve and preparation method thereof

A molecular sieve and small-grain technology, applied in the direction of crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc. Poor thermal stability and other problems, to achieve the effect of ensuring the continuity of the skeleton, good stability, and high crystallization retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of small grain NaY type molecular sieve of the present invention specifically comprises the following steps:

[0031] A. Preparation of directing agent at low temperature.

[0032] According to Na 2 O:Al 2 o 3 : SiO 2 :H 2 O=10~20: 1: 10~20: 300~400 feed molar ratio, at a temperature above 0°C and less than 15°C, preferably at a temperature of 0°C to 10°C, the water glass is slowly stirred under the condition of stirring Add it into the high-alkaline sodium metaaluminate solution and mix evenly, then stir at the above temperature at a constant temperature and speed for 0.5-2 hours; then seal the mixed solution in a synthesis kettle, and age it at a static temperature for 10-14 hours to obtain a directing agent The directing agent is preferably added with 20% to 40% of the weight of the directing agent before use.

[0033] B. Preparation of gel at low temperature.

[0034] Mix water glass, aluminum sulfate solution, low-alkali sodium metaalu...

Embodiment 1

[0048] This example is to prepare NaY molecular sieve with small crystal grains as raw material.

[0049] The raw materials used are as follows:

[0050] High alkali sodium metaaluminate: Na 2 O content 291g / L, Al 2 o 3 Content 42g / L; low alkali sodium metaaluminate: Na 2 O content 117g / L, Al 2 o 3 Content 77g / L; water glass: SiO 2 Content 250g / L, modulus 3.2; aluminum sulfate: Al 2 o 3 Content 90g / L.

[0051] Preparation of LY-1:

[0052] A. Preparation of guiding agent: Slowly add 1200ml of water glass into 800ml of peralkaline sodium metaaluminate under stirring condition at 10°C. After adding the water glass, stir at constant temperature for 40 minutes. Stirring was stopped, and the mixed solution was sealed in a container, and aged at a temperature of 5°C for 12 hours at a constant temperature. After the constant temperature is finished, add 667ml of clean water to the mixed solution as a guiding agent.

[0053] B. Preparation of gel: Add 59.4ml of aluminum su...

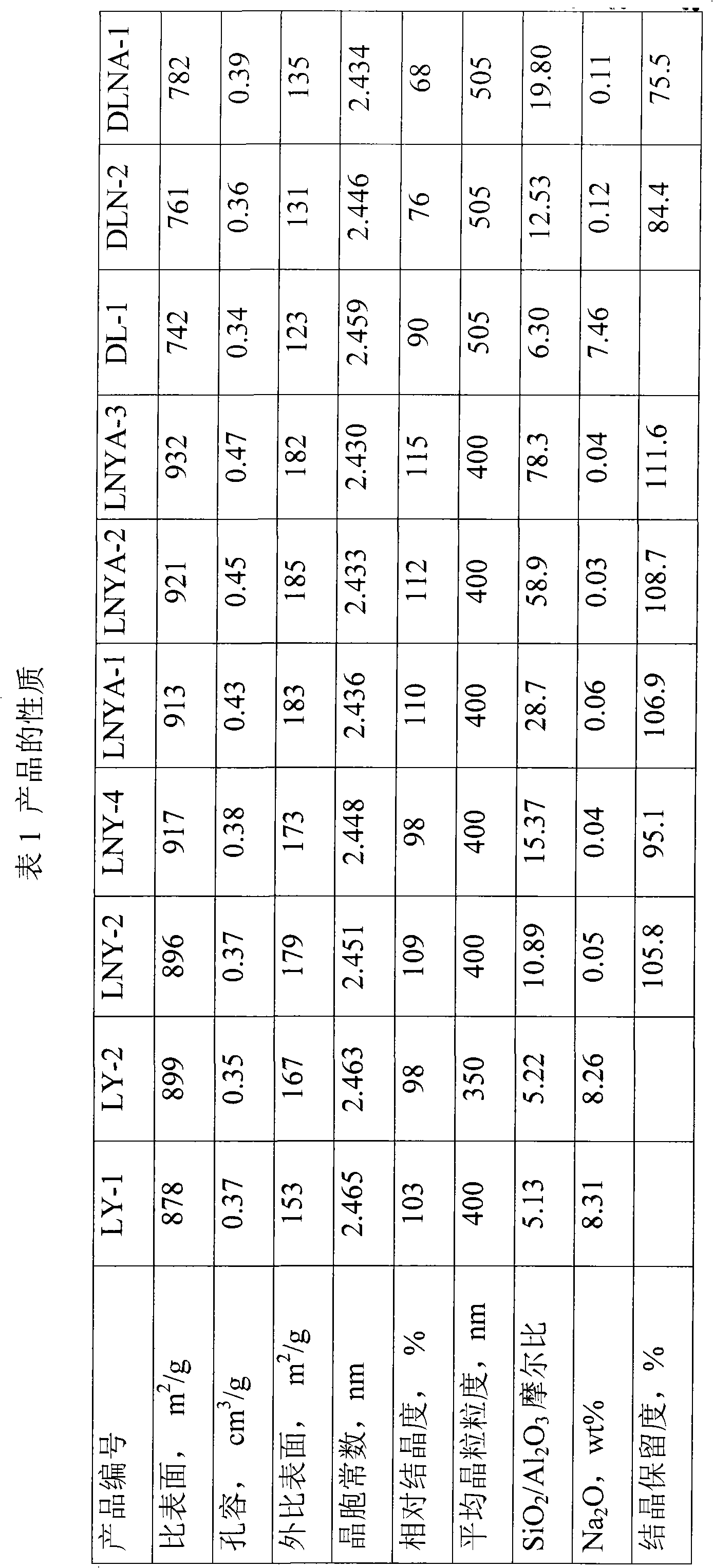

Embodiment 2

[0060] Firstly, ammonium exchange is carried out on the raw material small-grain NaY molecular sieve LY-1. The preparation concentration is 10 liters of 0.5mol / l ammonium nitrate aqueous solution. Weigh 2,000 grams of small-grain NaY molecular sieves, dissolve them in 10 liters of prepared ammonium nitrate aqueous solution, stir at 90°C for 1 hour at a constant temperature of 300 rpm, then filter the molecular sieves, and leave a small sample to analyze Na 2 O content; repeat the above operation until Na in the molecular sieve 2 The O content reaches 2.5-5wt%, and the sample number obtained after drying is LNY-1.

[0061] Measure 1 liter of clean water and dissolve 1000 g of LNY-1 in the clean water, heat up and stir rapidly, the temperature is 95°C, and the stirring speed is 300 rpm. Within 2 hours, add ammonium hexafluorosilicate aqueous solution to the molecular sieve slurry at a uniform speed, add a total of 50 grams of ammonium hexafluorosilicate, then stir at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com