Modified Y-type molecular sieve and preparation method thereof

A molecular sieve and modification technology, which is applied in the directions of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problem of low pore volume of modified Y molecular sieve, destruction of crystallinity of modified Y molecular sieve, low crystallinity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

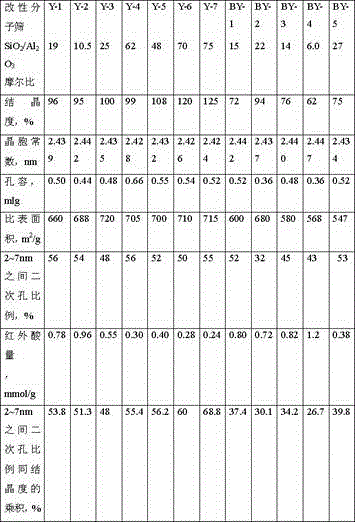

Examples

Embodiment 1

[0021] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 1.5mol / L according to the liquid-solid ratio of 4:1, exchange at 80°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 2.3%;

[0022] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 550°C and 0.1Mpa for 2 hours;

[0023] (3) Mix the Y molecular sieve obtained in step (2) with sodium nitrate with a concentration of 2.0mol / L according to the liquid-solid ratio of 5:1, exchange at 70°C for 1 hour, repeat this process twice, and the Na in the exchanged Y molecular sieve content in Na 2 O is calculated as 3.0%;

[0024] (4) The molecular sieve obtained in step (3) is mixed with 0.8 mol / L ammonium fluorosilicate solution according to the liquid-solid ratio of 5:1 and beaten, and treated at 90°C for 2 hours;

[0025] (5) The Y molecular sieve treated with ammo...

Embodiment 2

[0027] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium chloride with a concentration of 2.0mol / L according to the liquid-solid ratio of 5:1, exchange at 85°C for 2 hours, repeat this process twice, and the exchanged Y Na content in molecular sieve is Na 2 O is calculated as 1.7%;

[0028] (2) The Y molecular sieve obtained in step (1) was hydrothermally treated at 530°C and 0.1Mpa for 1.5 hours;

[0029] (3) Mix the Y molecular sieve obtained in step (2) with sodium nitrate with a concentration of 1.5mol / L according to the liquid-solid ratio of 5:1, exchange at 80°C for 1 hour, repeat this process twice, and the Na in the exchanged Y molecular sieve The content is 2.6% as Na2O;

[0030] (4) The molecular sieve obtained in step (3) is mixed with ammonium fluorosilicate solution with a concentration of 0.5 mol / L according to the liquid-solid ratio of 5:1 and beaten, and treated at 95°C for 2 hours;

[0031] (5) The Y molecular ...

Embodiment 3

[0033] (1) Take 200g of NaY molecular sieve raw powder prepared in the laboratory, mix it with ammonium nitrate with a concentration of 1.2mol / L according to the liquid-solid ratio of 3:1, exchange at 80°C for 2 hours, repeat this process twice, and the exchanged Y molecular sieve Na content in Na 2 O is calculated as 2.5%;

[0034] (2) Hydrothermally treat the Y molecular sieve obtained in step (1) at 550°C and 0.1Mpa for 2 hours;

[0035] (3) Mix the Y molecular sieve obtained in step (2) with a sodium chloride solution with a concentration of 1.7mol / L according to the liquid-solid ratio of 5:1, exchange at 65°C for 1 hour, repeat this process 3 times, and the Y molecular sieve after exchange Na content in Na 2O is calculated as 2.8%;

[0036] (4) The molecular sieve obtained in step (3) is mixed with ammonium fluorosilicate solution with a concentration of 0.7mol / L according to the liquid-solid ratio of 10:1 and beaten, and treated at 85°C for 2 hours;

[0037] (5) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com