A system for preventing the heating surface of the boiler from being contaminated by a double-fluidized bed combustion furnace

A double fluidized bed, fluidized bed technology, applied in the direction of fluidized bed combustion equipment, fuel burned in the molten state, combustion type, etc., can solve problems such as contamination, achieve extended operating time, small equipment investment, and solve the problem of coal The effect of powder transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

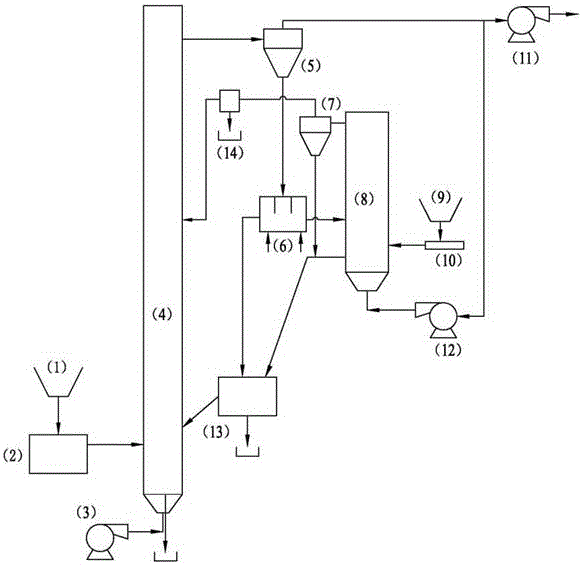

[0028] Such as figure 1 As shown, a double fluidized bed combustion furnace prevents the heating surface of the boiler from being contaminated, including a fluidized bed combustion furnace 4, a cyclone separator 5, a coal ash distributor 6, a fluidized bed pyrolysis furnace 8, and a fluidized bed combustion furnace The furnace 4 is connected with a first feeder 2, and the outlet at the upper end of the side wall of the fluidized bed combustion furnace 4 is connected to the inlet of the cyclone separator 5, and the cyclone separator 5 separates the high-temperature coal ash from the fluidized bed combustion furnace 4; The outlet at the bottom of the cyclone separator 5 is connected to the inlet of the coal ash distributor 6, and the separated high-temperature coal ash is passed into the coal ash distributor 6, and the top of the cyclone separator 5 is provided with a flue gas outlet; the coal ash distributor 6 is set There are a first coal ash outlet and a second coal ash outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com