Preparation method and application of {001} crystal face exposed porous titanium dioxide nanosheet

A technology of porous titanium dioxide and titanium dioxide, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of poor product morphology or performance, complicated process, high risk, etc., and achieve excellent photocatalytic performance , The preparation method is simple and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Accurately measure 20 mL of cyclohexanol, add 2 mmol of hexafluorotitanic acid and 2.5 mmol of tetrabutyl titanate in sequence, stir and dissolve to obtain a milky white solution; transfer the above solution to a closed, pressure-resistant homogeneous reaction vessel In the process, react at 180°C for 150 minutes at a rotation speed of 300 rpm; after the product is rapidly cooled to room temperature, it is repeatedly washed with deionized water and absolute ethanol, centrifuged, and dried in a vacuum to obtain a pure white powder product.

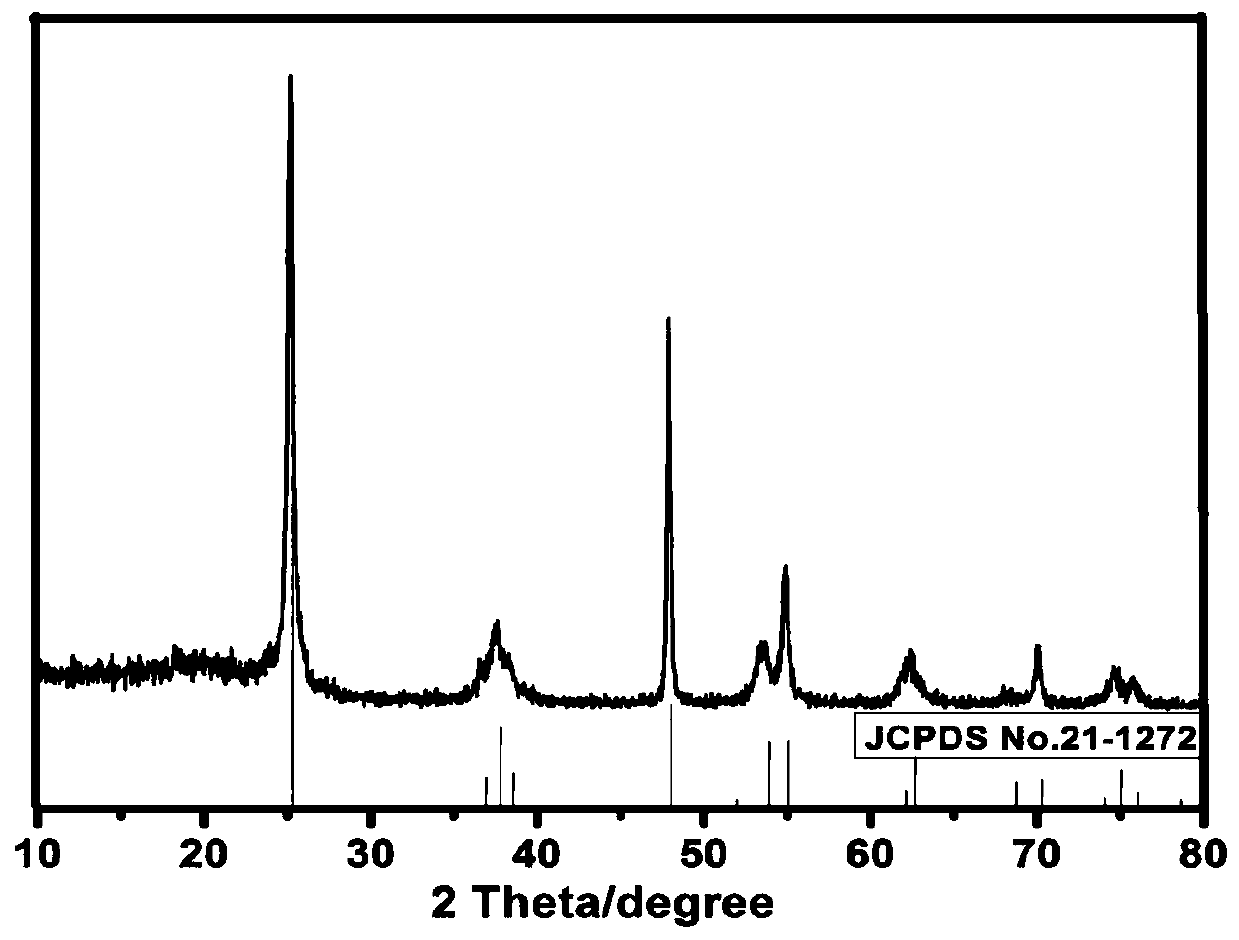

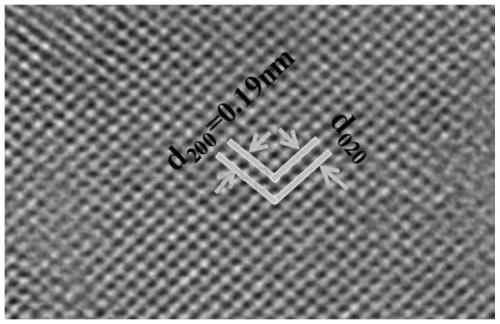

[0061] The product was subjected to Bruker D8 ADVANCE X-ray powder diffractometer (Cu Kα ray, wavelength The scanning step is 0.08° / sec) identified as anatase TiO 2 powder( figure 1 ), matched with the JCPDS card standard value (No.21-1272), and no other impurity peaks appeared.

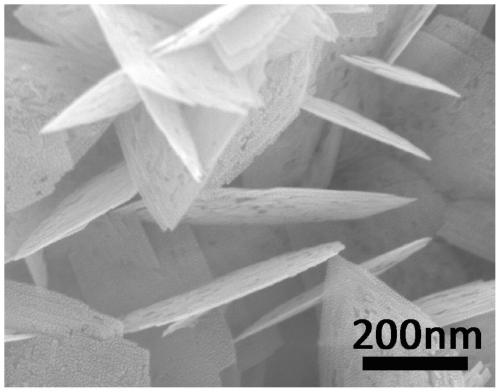

[0062] Observation of anatase TiO by SU-8200 scanning electron microscope 2 The morphology of the nanosheets, the results are as follows f...

Embodiment 2

[0067] Example 2: Accurately measure 15 mL of cyclohexanol, add 1 mmol of hexafluorotitanic acid and 3 mmol of tetrabutyl titanate in sequence, stir and dissolve to obtain a milky white solution; transfer the above solution to a closed, pressure-resistant homogeneous reaction vessel , at a rotation speed of 300rpm, reacted at 200°C for 180min; after the product was rapidly cooled to room temperature, washed repeatedly with deionized water and acetone, centrifuged, and then freeze-dried to obtain a pure white powder product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com