Colored chromium-free passivation solution

A chrome-free passivation and color technology, applied in the direction of metal material coating process, can solve the problems of affecting the long-term corrosion resistance of metals, difficult to obtain coating, etc., and achieve the effect of good passivation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

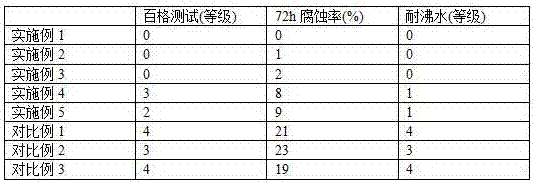

Examples

Embodiment 1

[0051] The colored chrome-free passivation solution consists of 3 parts by weight of fluorozirconic acid solution, 4 parts by weight of fluorotitanic acid, 2 parts by weight of ammonium metavanadate, 1 part by weight of tannic acid, 0.1 parts by weight of silica sol solution and 0.05 parts by weight The dispersant of parts by weight, the catechin gallate of 0.1 parts by weight, the nanometer tantalum oxide solution of 0.1 parts by weight and the water of 100 parts by weight, described fluozirconic acid solution is the aqueous solution containing 50%wt fluozirconic acid, the The fluorotitanic acid solution is an aqueous solution containing 50%wt fluorotitanic acid, the silica sol solution is an aqueous solution containing 30%wt silicon dioxide, and the nano-tantalum oxide solution is an aqueous solution containing 15%wt nano-tantalum oxide.

[0052] The nanometer tantalum oxide solution is prepared through the following steps:

[0053] 8 parts by weight of tantalum pentachlorid...

Embodiment 2

[0060] The colored chrome-free passivation solution consists of 3 parts by weight of fluorozirconic acid solution, 4 parts by weight of fluorotitanic acid, 2 parts by weight of ammonium metavanadate, 1.2 parts by weight of tannic acid, 0.13 parts by weight of silica sol solution and 0.05 parts by weight The dispersant of parts by weight, the catechin gallate of 0.08 parts by weight, the nanometer tantalum oxide solution of 0.08 parts by weight and the water of 100 parts by weight, described fluozirconic acid solution is the aqueous solution containing 50%wt fluozirconic acid, the The fluorotitanic acid solution is an aqueous solution containing 50%wt fluorotitanic acid, the silica sol solution is an aqueous solution containing 30%wt silicon dioxide, and the nano-tantalum oxide solution is an aqueous solution containing 15%wt nano-tantalum oxide.

[0061] The nanometer tantalum oxide solution is prepared through the following steps:

[0062] 8 parts by weight of tantalum pentac...

Embodiment 3

[0069] The colored chrome-free passivation solution consists of 3 parts by weight of fluorozirconic acid solution, 4 parts by weight of fluorotitanic acid, 2 parts by weight of ammonium metavanadate, 0.8 parts by weight of tannic acid, 0.07 parts by weight of silica sol solution and 0.05 parts by weight The dispersant of parts by weight, the catechin gallate of 0.12 parts by weight, the nanometer tantalum oxide solution of 0.12 parts by weight and the water of 100 parts by weight, described fluozirconic acid solution is the aqueous solution containing 50%wt fluozirconic acid, the The fluorotitanic acid solution is an aqueous solution containing 50%wt fluorotitanic acid, the silica sol solution is an aqueous solution containing 30%wt silicon dioxide, and the nano-tantalum oxide solution is an aqueous solution containing 15%wt nano-tantalum oxide.

[0070] The nanometer tantalum oxide solution is prepared through the following steps:

[0071] 8 parts by weight of tantalum pentac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com