Environment-friendly low-cost metal surface treatment agent and preparation method thereof

A metal surface treatment, low-cost technology, applied in the direction of metal material coating process, etc., can solve the problems of poor film adhesion and corrosion resistance, dust hanging, environmental pollution, etc., and achieve the effect of low energy consumption and low use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

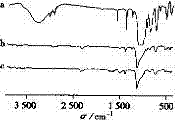

Image

Examples

Embodiment 1

[0037] Take 15 grams of 3-aminopropyltriethoxysilane, 15 grams of dispersible nano-silica, 15 grams of fluotitanic acid, 25 grams of fluozirconic acid, 5 grams of oxalic acid, 8 grams of hydrogen peroxide, 912 grams of water, and 5 grams of ammonia water , produced by the following preparation method:

[0038] (1) Weigh 15 grams of 3-aminopropyltriethoxysilane and add it to 300 grams of water (the conductivity of the water is <10 μs / cm), stir rapidly for 10 minutes to fully dissolve it, and then prepare the semi-finished product A;

[0039] (2) Weigh 15 grams of dispersible nano-silica and add it to 300 parts of water (water conductivity <10μs / cm), stir rapidly for 20 minutes to fully dissolve, add 25 grams of fluozirconic acid and 15 grams of fluotitanic acid, After stirring for 10 minutes, semi-finished product B was obtained;

[0040] (3) Take 5 grams of oxalic acid and add it to 100 grams of water, stir for 10 minutes to dissolve it completely, then add 8 grams o...

Embodiment 2

[0043] Take 20 grams of 3-aminopropyltriethoxysilane, 20 grams of dispersible nano-silica, 25 grams of fluotitanic acid, 15 grams of fluozirconic acid, 10 grams of oxalic acid, 15 grams of hydrogen peroxide, 890 grams of water, and 5 grams of ammonia water , produced by the following preparation method:

[0044] (1) Weigh 20 grams of 3-aminopropyltriethoxysilane and add it to 300 grams of water (the conductivity of the water is <10 μs / cm), stir rapidly for 10 minutes to fully dissolve it, and then prepare the semi-finished product A;

[0045] (2) Weigh 20 grams of dispersible nano-silica and add it to 300 parts of water (the conductivity of water is <10 μs / cm), stir rapidly for 20 minutes to fully dissolve, add 15 grams of fluozirconic acid and 25 grams of fluotitanic acid, After stirring for 10 minutes, semi-finished product B was obtained;

[0046] (3) Take 10 grams of oxalic acid and add it to 100 grams of water, stir for 10 minutes to dissolve it completely, then...

Embodiment 3

[0049] Take 10 grams of 3-aminopropyltriethoxysilane, 10 grams of dispersible nano-silica, 10 grams of fluotitanic acid, 20 grams of fluozirconic acid, 10 grams of oxalic acid, 8 grams of hydrogen peroxide, 930 grams of water, and 10 grams of ammonia water, The preparation method and steps are the same as in Example 1.

[0050] Among them, 3-aminopropyltriethoxysilane (γ-APS) is the main film-forming substance, and their mutual crosslinking can form a dense silane adsorption film on the metal surface; dispersible silica is the auxiliary film-forming substance , to fill the gaps in the silane adsorption film; fluozirconic acid and fluotitanic acid are mainly used to increase the density of the silane adsorption film and improve the film quality of the silane adsorption film; oxalic acid is used to adjust the pH value of the treatment agent (reduce the pH Value), promote the hydrolysis of silane and accelerate its film formation process; hydrogen peroxide is mainly used to incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com