Coating agent for thermally insulating material and laminate for thermally insulating material using the same

A technology of thermal insulation materials and coating agents, applied in the direction of coatings, layered products, fireproof coatings, etc., can solve problems such as low oxidation resistance and mechanical strength, insufficient surface smoothness and surface gloss, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

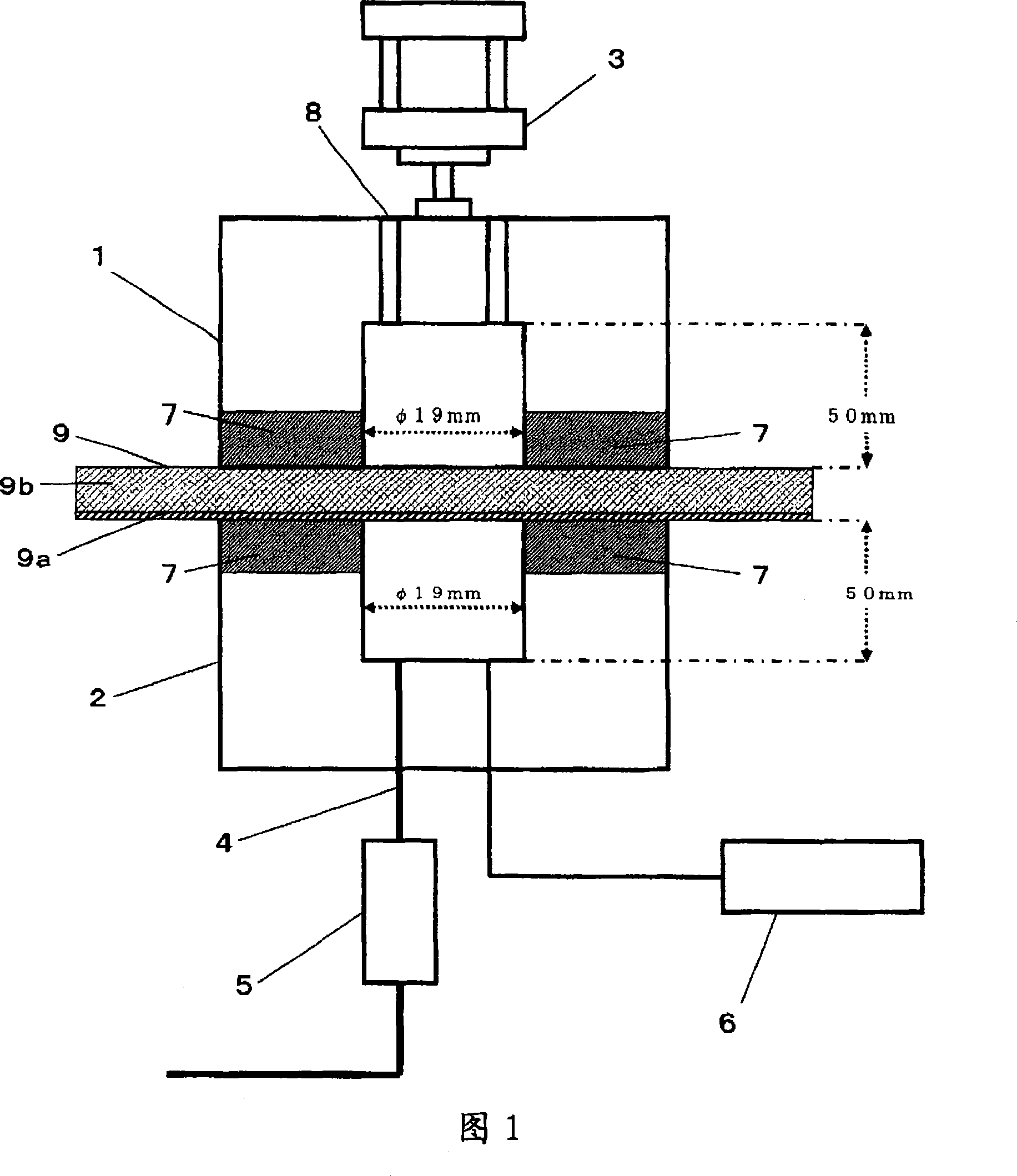

Image

Examples

Embodiment 1

[0136] 〔Preparation of carbonized molded body〕

[0137] With respect to 100 parts by mass of a pitch-based carbon fiber felt (manufactured by Kureha Chemical Industry Co., Ltd., "Kurekafelt F-110") with an average fiber length of 50 mm, a phenol resin-based impregnating solution (manufactured by Showa Polymer Co., Ltd., trade name " 44 parts by mass of シヨウノール BRS-3896") was laminated in six layers in a flat plate to obtain a laminate. Next, the laminate thus obtained was press-molded under conditions of a temperature of 150° C. and a pressure of 0.015 MPa to cure the resin. Then, the laminate obtained by curing the resin in this way was further subjected to graphitization treatment in vacuum at a temperature of 2000° C. for 1 hour to obtain a felt with a bulk density of 0.16 g / cm 3 flat carbon fiber felt laminate (carbonized molded body: thickness 48mm).

[0138] [Preparation of coating agent for thermal insulation materials]

Embodiment 2

[0144] Carry out in the same manner as the preparation sequence of the carbonized molded body in Example 1, and carry out graphitization treatment at 2000° C. so that its bulk density reaches 0.12 g / cm 3 , except using the thus prepared bulk density of 0.12 g / cm 3 The carbon fiber felt laminated body (carbonized molded body) to replace the bulk density prepared in Example 1 is 0.16g / cm 3 Except for the carbon fiber felt laminated body, the same procedure as in Example 1 was carried out to produce a laminated body for a heat insulating material and a sample used in each test. The surface of the coating layer for a heat insulating material laminated on the thus obtained laminate for a heat insulating material was smooth and glossy.

Embodiment 3

[0146] Carry out in the same manner as the preparation sequence of the carbonized molded body in Example 1, and carry out graphitization treatment at 2000° C. so that its bulk density reaches 0.4 g / cm 3 , except using the thus prepared bulk density of 0.4 g / cm 3 The carbon fiber felt that replaces the bulk density prepared in embodiment 1 is 0.16g / cm 3 Except for the carbon fiber felt laminated body, the same procedure as in Example 1 was carried out to prepare a laminated body for a heat insulating material and a sample used in each test. The surface of the coating layer for a heat insulating material laminated on the thus obtained laminate for a heat insulating material was smooth and glossy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com