Gas sampling room

A technology of gas sampling and sampling chamber, which is applied in the direction of sampling device, measuring device, material analysis through optical means, etc., to achieve the effect of improving the ability to resist dust or water vapor interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention should not be limited to these embodiments.

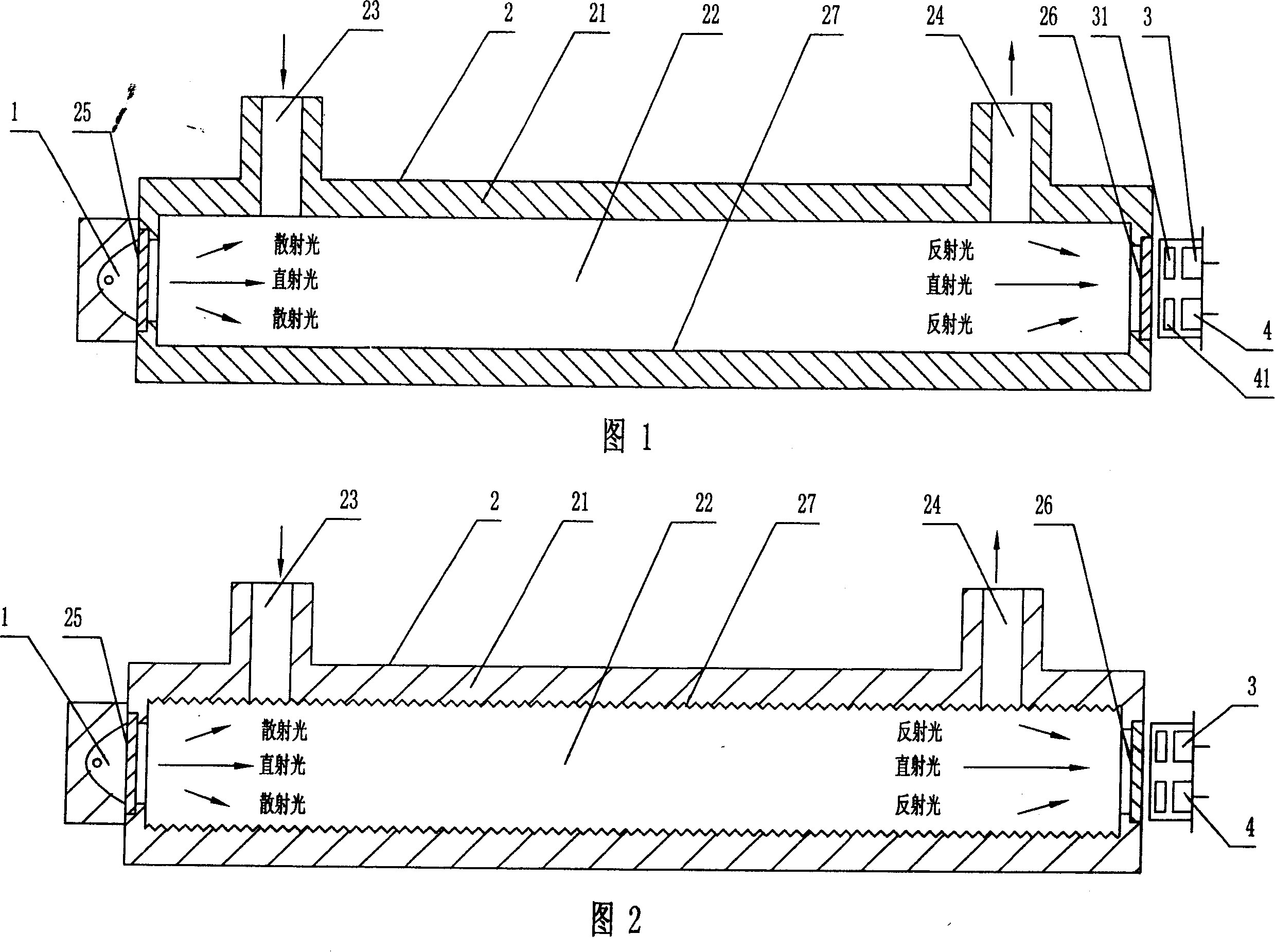

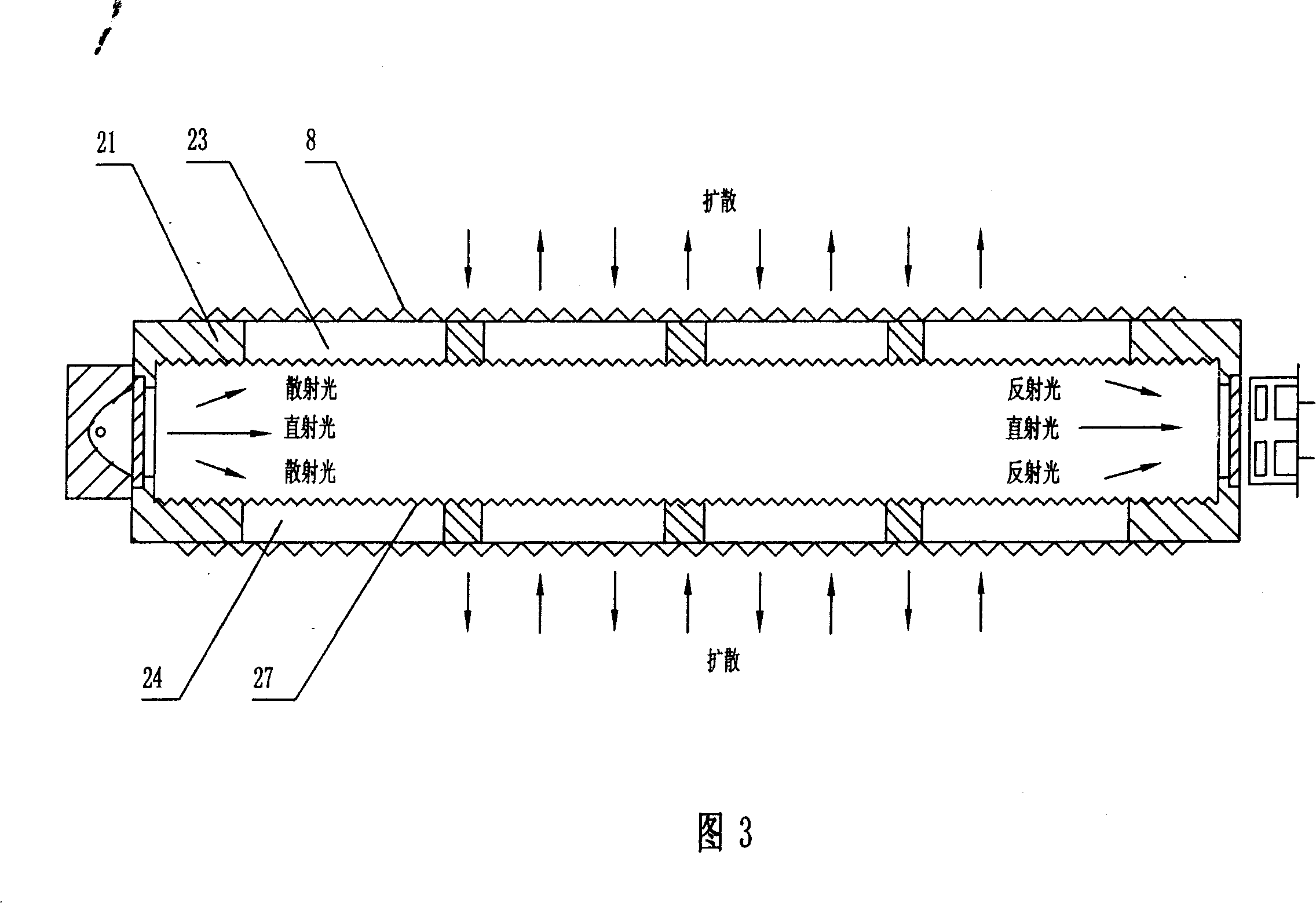

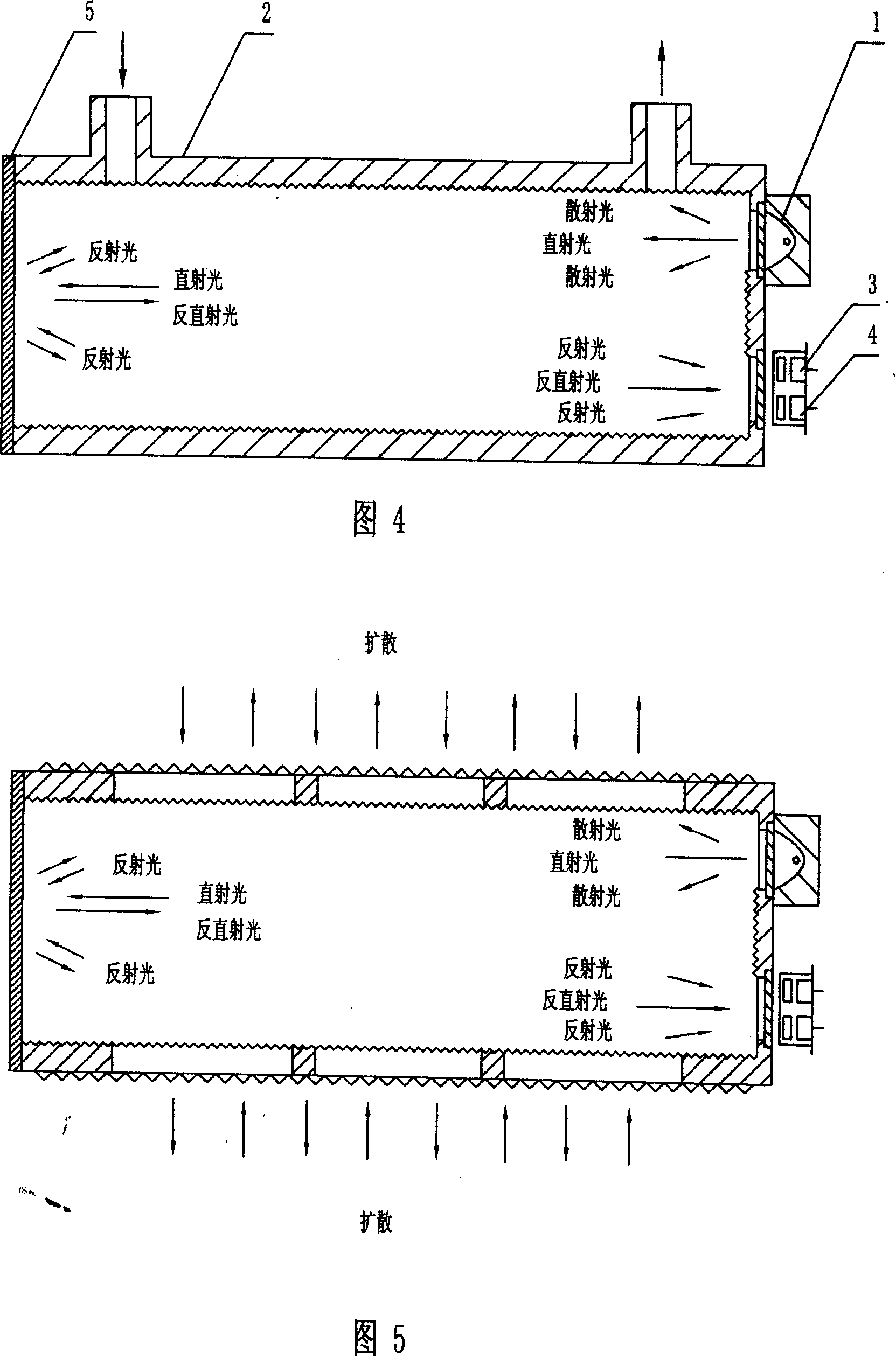

[0027] As shown in Figure 2, in the present embodiment, the structure of the gas sampling chamber 2 is as follows: the cavity 21 of the gas sampling chamber is provided with openings 23 and 24 through which the inner cavity 22 communicates with the outside world, and in the cavity of the sampling chamber 21 is also provided with windows 25 and 26 that allow light to pass through, and, on the inner cavity wall 27 of the sampling chamber cavity 21, is provided with an impeding reflection layer made of a material with near zero infrared reflectivity—it can be formed by the The material that strongly absorbs infrared light is made, or the inner surface is coated with a material that strongly absorbs infrared light, and the surface of the inner cavity wall 27 of the sampling chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com