Organic phase-change material microcapsules in narrow particle size distribution and preparation method thereof

An organic phase and microcapsule technology, applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problem of hindering uniform heat transfer temperature field, unfavorable phase change material control temperature and heat storage performance, organic phase change Microcapsule particles are difficult to meet the needs of fine compounding and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides an organic phase change material microcapsule and a preparation method thereof, the method sequentially includes an emulsion emulsification stage, a microencapsulation stage and a post-treatment stage;

[0073] specific:

[0074] (1) configuration mass concentration is the styrene-maleic anhydride copolymer solution of 2.5wt% as emulsifier, it is added in liquid paraffin and simply stirred to obtain pre-emulsion;

[0075] (2) the pre-emulsion prepared in step (1) is pressed through a porous membrane with a pore size of 10.1 μm under a membrane pressure of 0.1 MPa to obtain uniform emulsion droplets with a particle size for 4 times;

[0076] (3) The melamine-formaldehyde prepolymer solution whose mass concentration is 2.88wt% is prepared, and slowly added dropwise to the emulsion droplets prepared in step (2) under the condition of a stirring rate of 200r / min at 70°C, dripping After the addition is completed, increase the stirring rate to 600r / m...

Embodiment 2

[0080] This example provides an organic phase change material microcapsule and a preparation method thereof. In the method, except that the membrane pressure in step (2) is 0.3 MPa, other preparation methods and conditions are the same as those in Example 1.

[0081] The average particle size of the liquid paraffin microcapsules prepared in this example is 6.70 μm, the relative standard deviation is 0.33, the particle size distribution range is wider than that of Example 1, and the number of small particle size microcapsules increases.

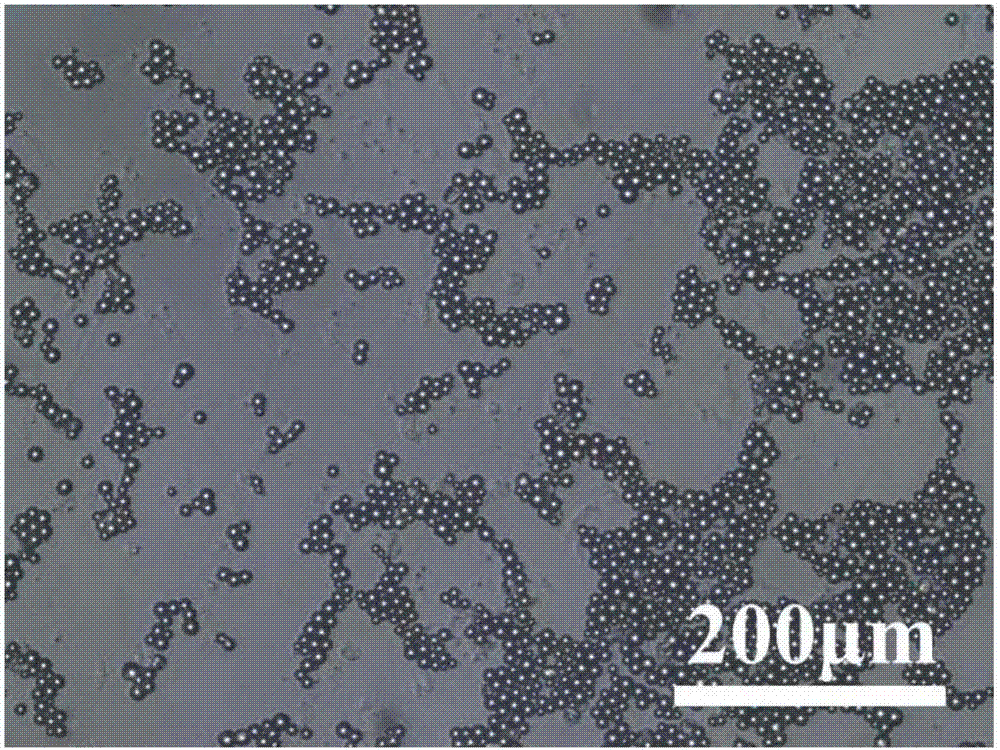

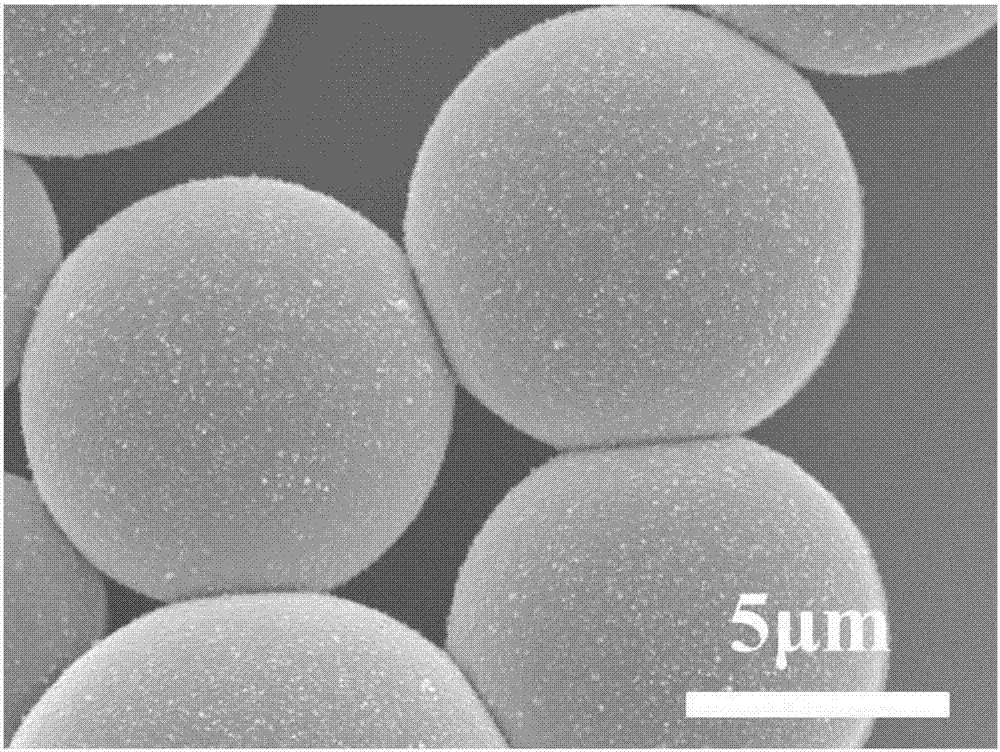

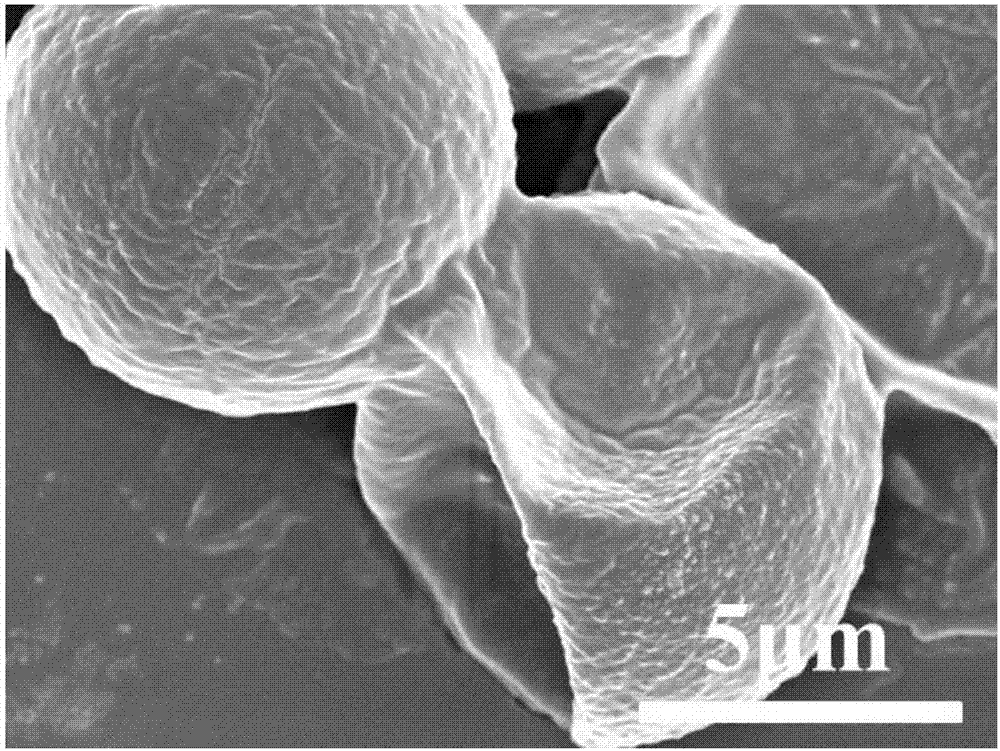

[0082] The liquid paraffin microcapsule optical microscope photo that makes in the present embodiment is as figure 1 As shown, the scanning electron microscope pictures are shown as figure 2 As shown, the particle size distribution diagram is shown in Figure 4 As shown, it can be seen that the particle size distribution of the microcapsule product prepared in this embodiment is narrow, and the surface is smooth and dense, and basically no a...

Embodiment 3

[0085] This embodiment provides a kind of microcapsule of organic phase change material and preparation method thereof, described method is except that the number of passing membrane in step (2) is 1 time, and passing membrane pressure is 0.2MPa, other preparation methods and conditions are all the same as Same as in Example 1.

[0086] The average particle size of the liquid paraffin microcapsules prepared in this example was 14.51 μm, and the relative standard deviation was 0.30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com