Method for preparing rose hip seed oil microcapsules

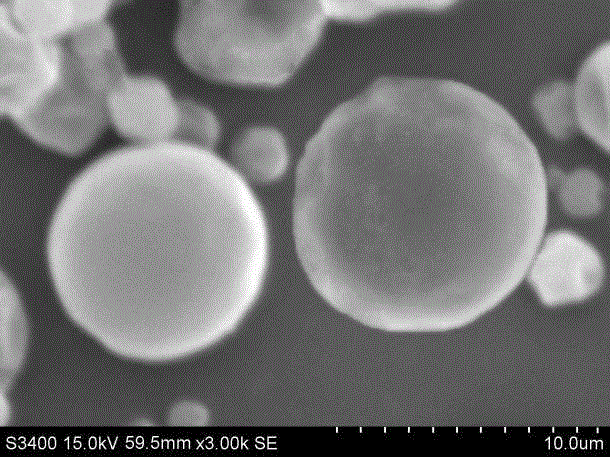

A technology for rosehip seed oil and microcapsules, which is applied in the fields of food preparation, oil-containing food ingredients, food science, etc., can solve the problems of uneven particles, sunken surface of fruit seed oil microcapsules, irregular shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] To prepare rosehip seed oil:

[0029] After the rosehip seeds are crushed, they are extracted with supercritical fluid; the extraction temperature is 50°C, the separation 1 temperature is 50°C, the separation 2 temperature is 35°C, the extraction pressure is 25Mpa, the separation 1 pressure is 8Mpa, and the separation 2 pressure is 4.5Mpa.

Embodiment 2

[0031] Prepare the wall material composition:

[0032] Mix starch octenyl succinate and maltodextrin uniformly according to the mass ratio of 1:1, 2:1, 3:1, and 4:1, respectively, to obtain wall material compositions 1, 2, 3, and 4;

[0033] Starch octenyl succinate, maltodextrin and sodium tripolyphosphate were uniformly mixed at a mass ratio of 4:0.5:0.05 to obtain wall material composition 5.

Embodiment 3

[0035] The rosehip seed oil prepared in Example 1 is used as the core material, and the wall material composition 1-5 prepared in Example 2 is used as the wall material respectively, and the rosehip seed oil microcapsules 1-5 are prepared by the following method;

[0036] (1) Preparation of wall material solution

[0037] Dissolve the wall material composition in distilled water at 40°C with a solid content of 15% by weight;

[0038] (2) Mixture preparation

[0039] After adding 25% rosehip seed oil (relative to the total mass of the wall material and the core material) to the wall material liquid, use a disperser at 10000r / min high-speed shear for 3min to obtain a mixed solution;

[0040] (3) homogeneous

[0041] Pour the mixed liquid into a homogenizer with a pressure of 40MPA and homogenize twice to obtain a stable emulsion;

[0042] (4) spray drying

[0043] The emulsion is spray-dried, the air inlet temperature is 180°C, the outlet temperature is 80°C, and finally the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com